Coke powder-based cathode material of lithium ion power battery and preparation method thereof

A technology of negative electrode material and power battery, which is applied in the field of lithium ion battery material preparation, can solve the problems of low degree of graphitization, poor rate performance, low initial efficiency, etc. of products, and achieves easy industrial production, low cost and low preparation cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

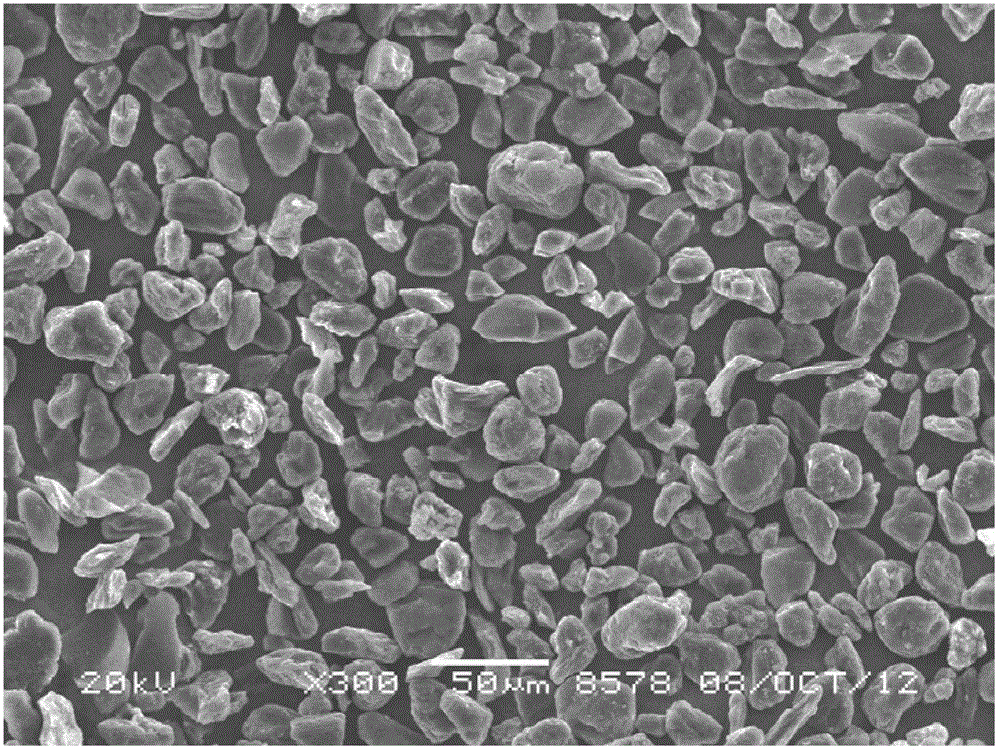

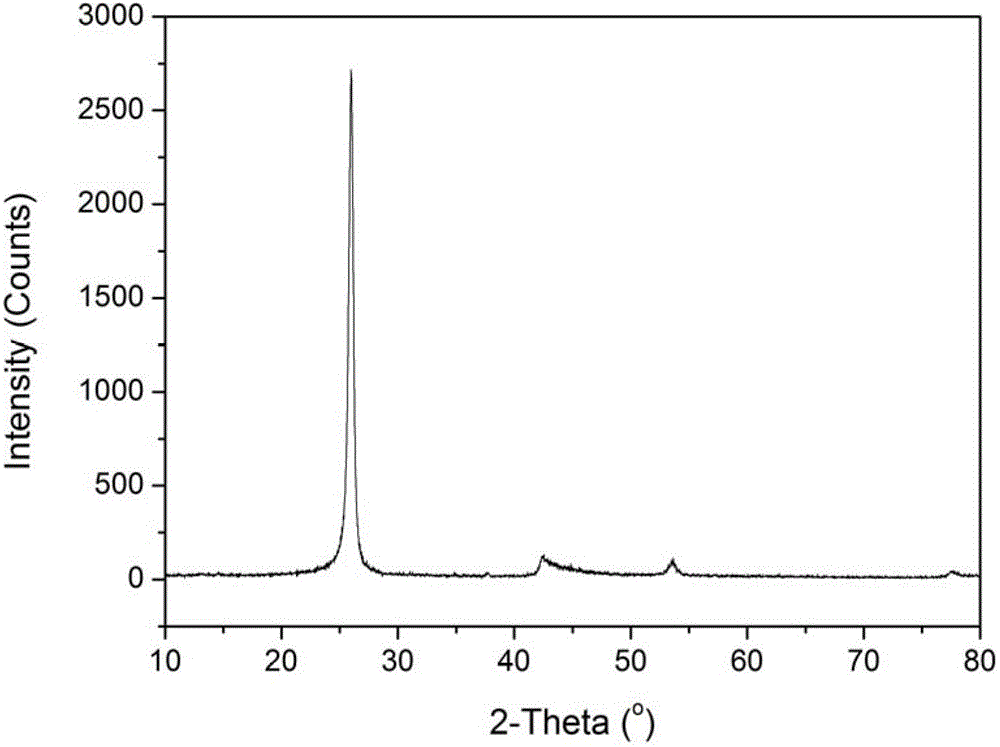

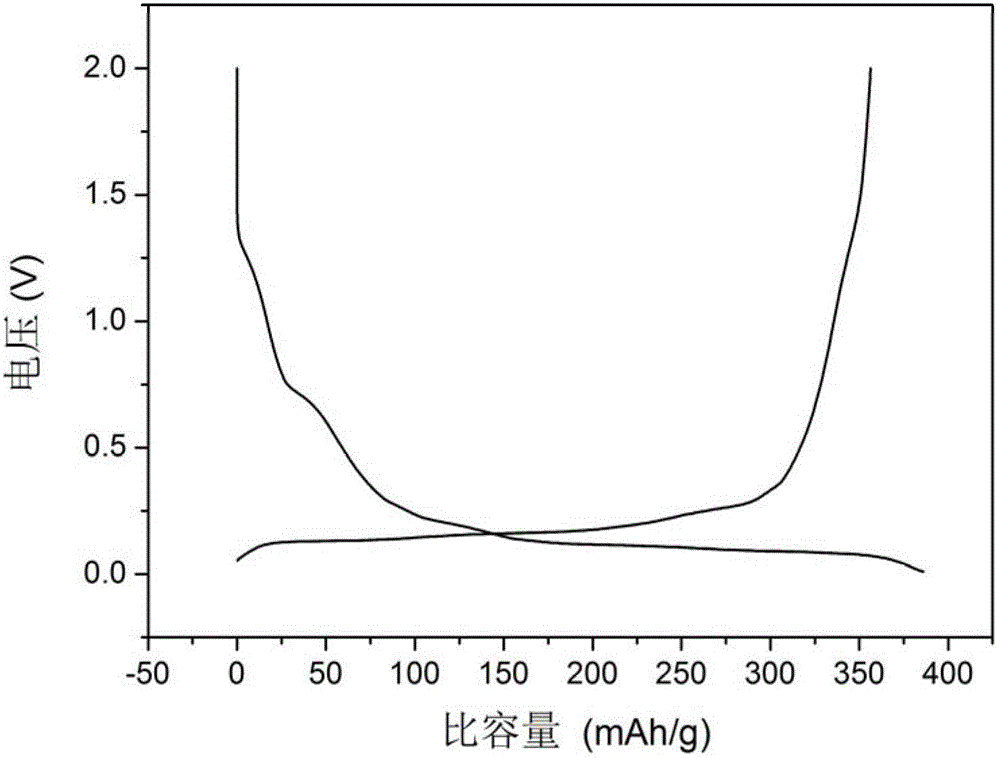

[0037]A coal coke powder-based negative electrode material for lithium-ion power batteries. Its core is graphitized coke powder. The mass fraction of Ag is 1%, D50 is 22um, the minimum particle size is 5um, the maximum particle size is 30um, and the tap density is 1.1g / cm 3 .

[0038] A method for preparing a coal coke powder-based negative electrode material for lithium-ion power batteries by using coal-based coke powder as a raw material comprises the following steps:

[0039] (1) Dry coal-based coke powder with an average particle size of 0.5mm and an ash content of 11% in a blast furnace at 120°C for 24 hours, then use a vortex jet mill to crush it into an average particle size of 20 μm, and classify the particle size range 5-30μm particles.

[0040] (2) Leach the materials that meet the particle size range with a hydrofluoric acid solution with a mass concentration of 19%. The coke powder is washed to neutral and then dried, and the purified coke powder obtained has a ...

Embodiment 2

[0046] A coal coke powder-based negative electrode material for lithium-ion power batteries. Its core is graphitized coke powder. The mass fraction of Cu is 2%, the D50 is 17um, the minimum particle size is 5um, the maximum particle size is 30um, and the tap density is 1.18g / cm 3 .

[0047] A method for preparing a coal coke powder-based negative electrode material for lithium-ion power batteries by using coal-based coke powder as a raw material comprises the following steps:

[0048] (1) Dry coal-based coke powder with an average particle size of 0.5mm and an ash content of 11% in a blast furnace at 130°C for 24 hours, and then use a vortex jet mill to crush it into an average particle size of 15 μm, and classify the particle size range 5-30μm particles.

[0049] (2) Leach the materials that meet the particle size range with a hydrofluoric acid solution with a mass concentration of 19%. The coke powder is washed to neutral and then dried, and the purified coke powder obtai...

Embodiment 3

[0055] A coal coke powder-based negative electrode material for lithium-ion power batteries. Its core is graphitized coke powder. The shell is composed of coal tar pitch pyrolysis carbon and electroless metal Ni plating on the surface of the shell. The mass fraction of Ni particles is 4%, D50 is 22um, the minimum particle size is 5um, the maximum particle size is 30um, and the tap density is 1.1g / cm 3 .

[0056] A method for preparing a coal coke powder-based negative electrode material for lithium-ion power batteries by using coal-based coke powder as a raw material comprises the following steps:

[0057] (1) Dry coal-based coke powder with an average particle size of 0.5mm and an ash content of 11% in a blast furnace at 140°C for 12 hours, and then use a vortex jet mill to crush it into an average particle size of 20 μm, and classify the particle size range 5-30μm particles.

[0058] (2) Leach materials that meet the particle size range with a mixed solution of hydrofluori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com