Electronic pilot burner

An ever-bright lamp and electronic technology, applied in lighting and heating equipment, combustion ignition, combustion methods, etc., can solve problems such as damage to supporting equipment, consumption of combustible gas, and large space occupation, and achieve convenient maintenance, saving equipment investment, and saving resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings.

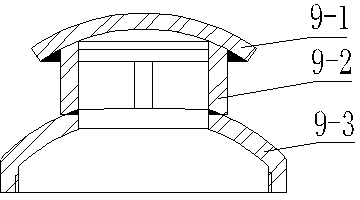

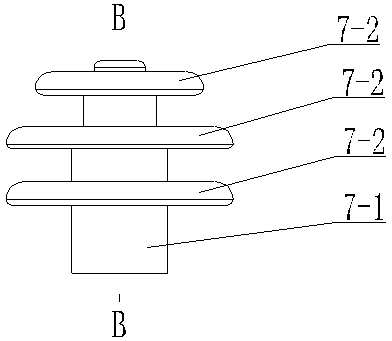

[0047]As shown in the accompanying drawings, the present invention has a metal conductive rod 1 used to be connected with a high voltage device. The length of the metal conductive rod 1 is 1800 mm to 2700 mm, and the top of the metal conductive rod 1 is processed with external threads. In order to ensure reliable The high-voltage electricity is sent to the discharge ignition head, and the metal conductive rod 1 is covered with a quartz protection tube 2, and the quartz protection tube 2 is composed of at least 3 stepped quartz tubes 2-1 connected to each other. Tube 2-1 The inner diameter of the thin tube section is 6-8mm, and the inner diameter of the thick tube section is 14-18mm. The length is adjusted with the voltage level to ensure the minimum discharge distance and meet the needs of relatively slender metal conductive rods, and enhance its performance in tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com