Niobium-aluminum alloying molybdenum disilicide material and preparation method thereof

A molybdenum disilicide and aluminum alloy technology, applied in the field of intermetallic compounds, can solve the problems of insignificant contribution to the fracture toughness at room temperature, and achieve the effects of low cost, reduced residual and reduced pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

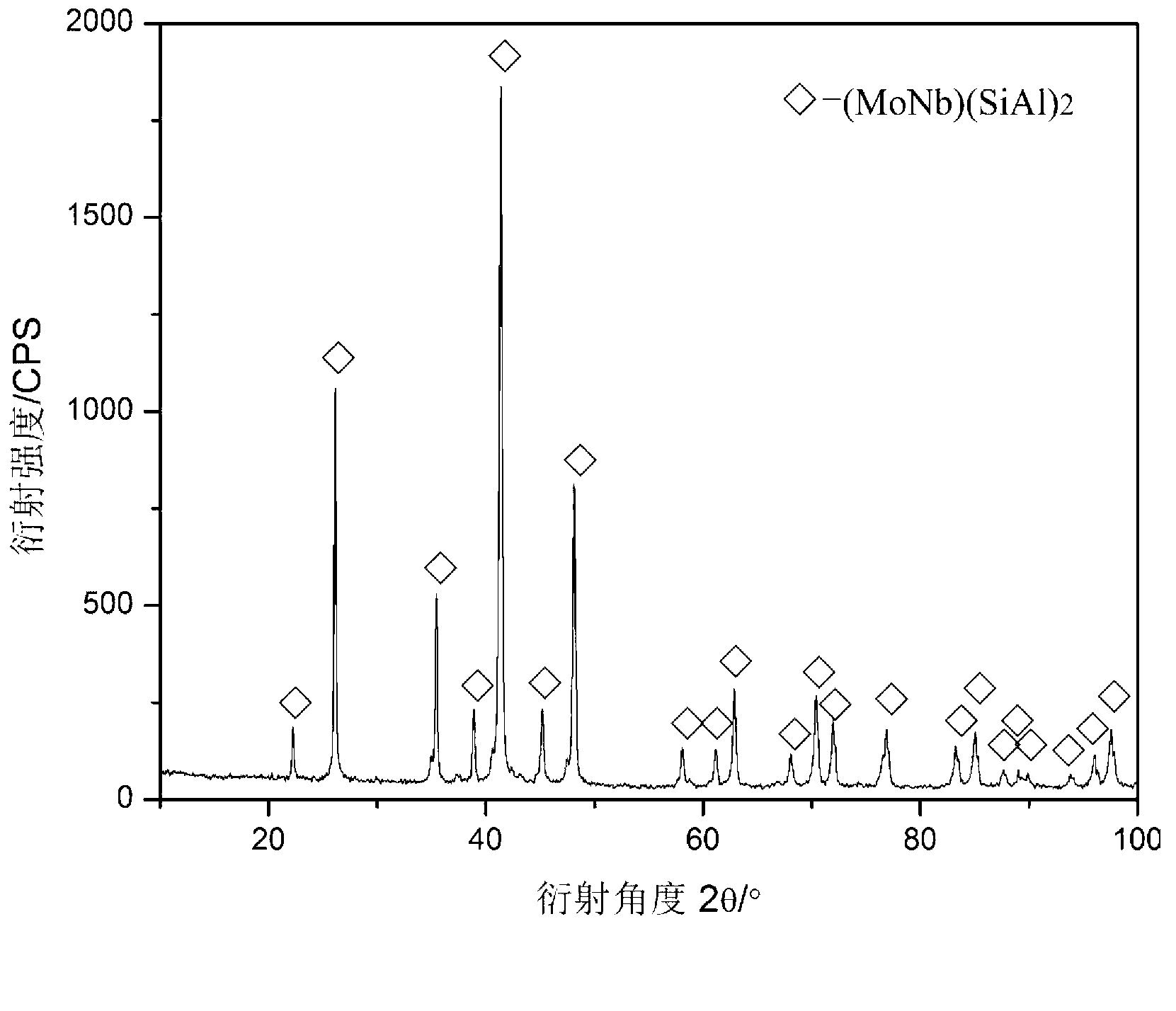

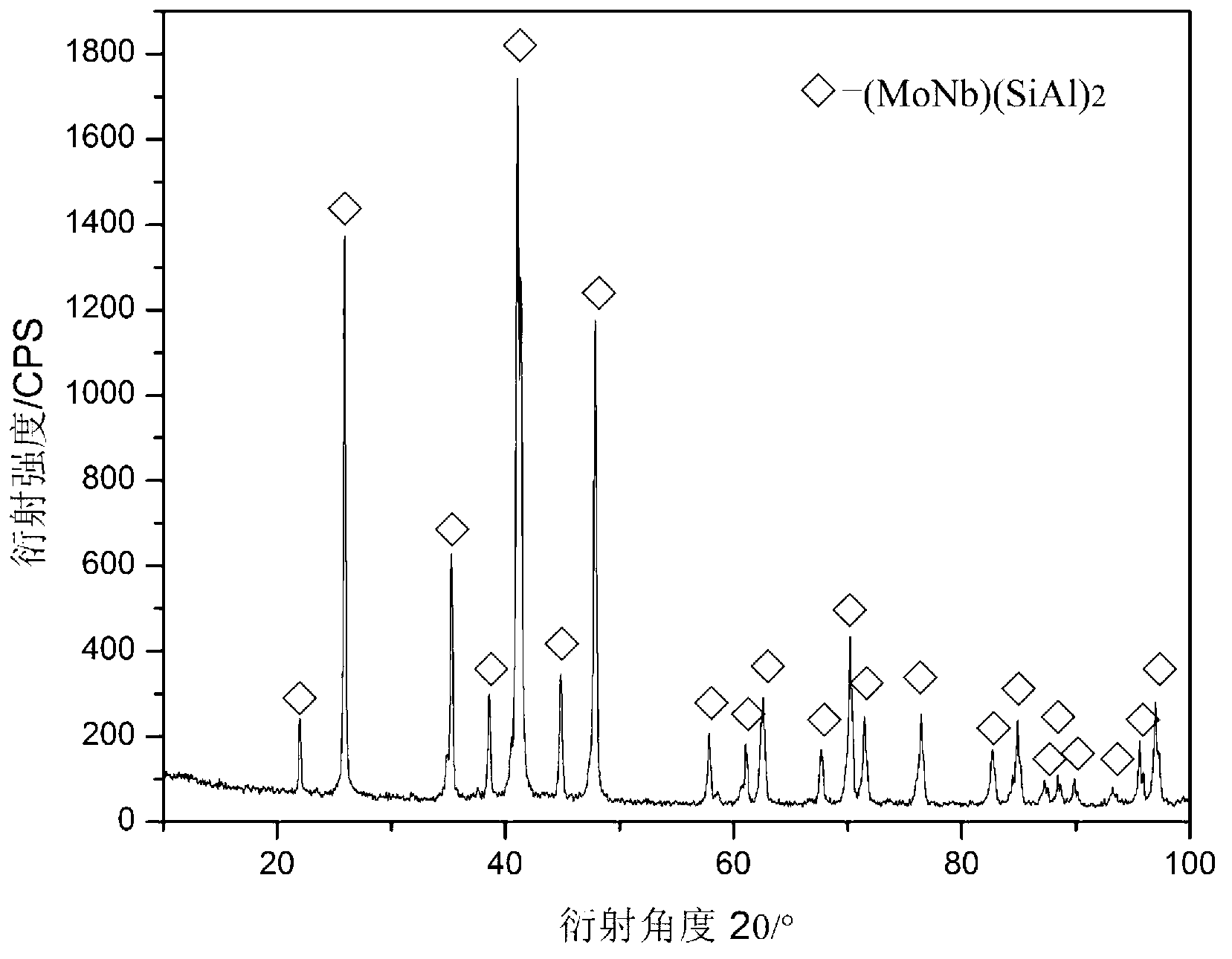

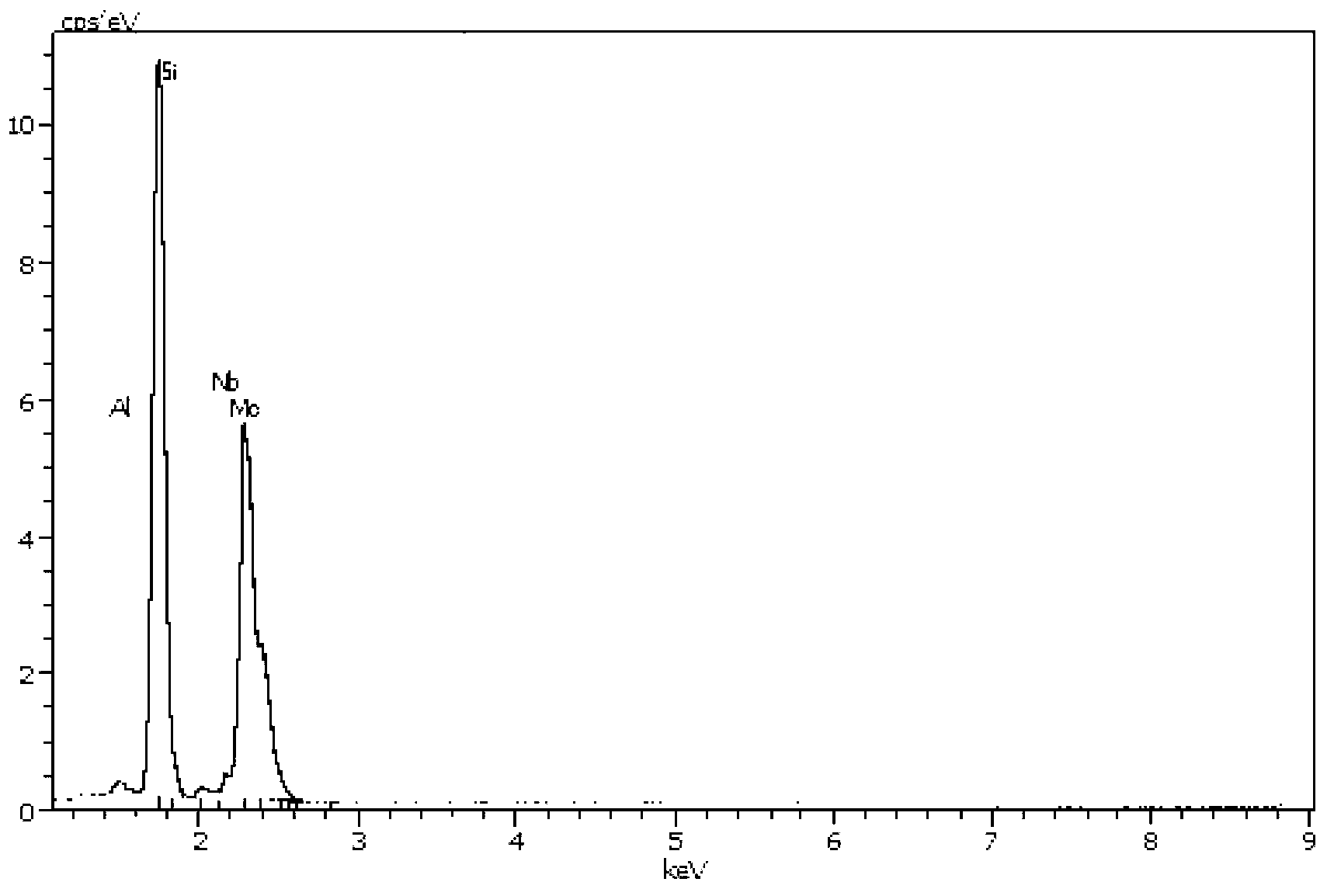

[0016] Embodiment 1. Mix the powders of molybdenum, niobium, silicon, and aluminum according to the molar ratio of 33.3mol% Mo, 0mol% Nb, 66.7mol% Si, and 0mol% Al, and press the mixed powder into a green body, and put the green body into In the combustion synthesis reaction device, the powder green body is ignited in an argon atmosphere environment, and the reaction occurs to synthesize MoSi 2 . After sintering and densification, its high temperature strength reaches 118MPa.

Embodiment 2

[0017] Embodiment 2. Mix the powders of molybdenum, niobium, silicon, and aluminum according to the molar ratio of 32.301mol% Mo, 0.999mol% Nb, 66.7mol% Si, and 0mol% Al, and press the mixed powder into a green body, and put the green body into the combustion synthesis reaction device, and ignite the powder green body in the hydrogen atmosphere environment, and the reaction synthesis (Mo 0.97 Nb 0.03 ) Si 2 .

Embodiment 3

[0018] Embodiment 3. Mix the powders of molybdenum, niobium, silicon, and aluminum according to the molar ratio of 30.303mol% Mo, 2.997mol% Nb, 66.7mol% Si, and 0mol% Al, and press the mixed powder into a green body, and put the green body Into the combustion synthesis reaction device, ignite the powder green body in the nitrogen atmosphere environment, and the reaction synthesis (Mo 0.91 Nb 0.09 ) Si 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com