High-temperature-resistant silane-crosslinked flame-retardation insulating material for automobile wires and preparation method thereof

A flame-retardant insulating material and silane cross-linking technology, applied in the direction of insulated conductors, insulated cables, cable/conductor manufacturing, etc., can solve the problems of increased transportation costs, high irradiation costs, etc., to achieve good wear resistance and low cost , good aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

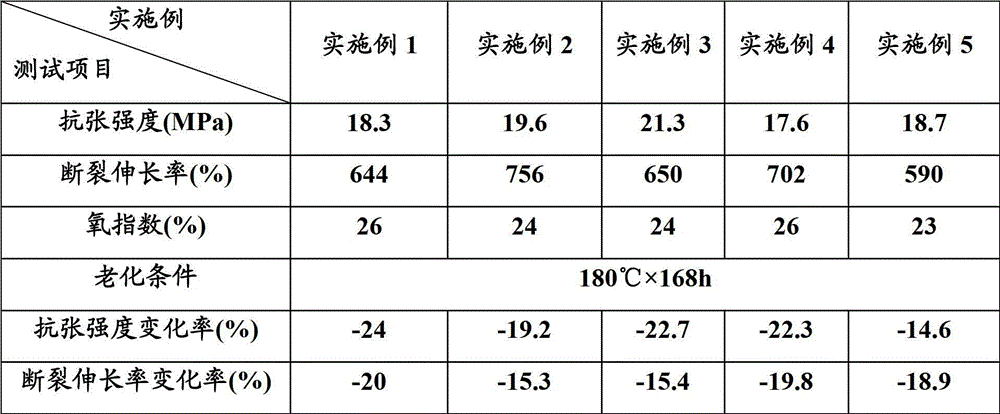

Examples

Embodiment 1

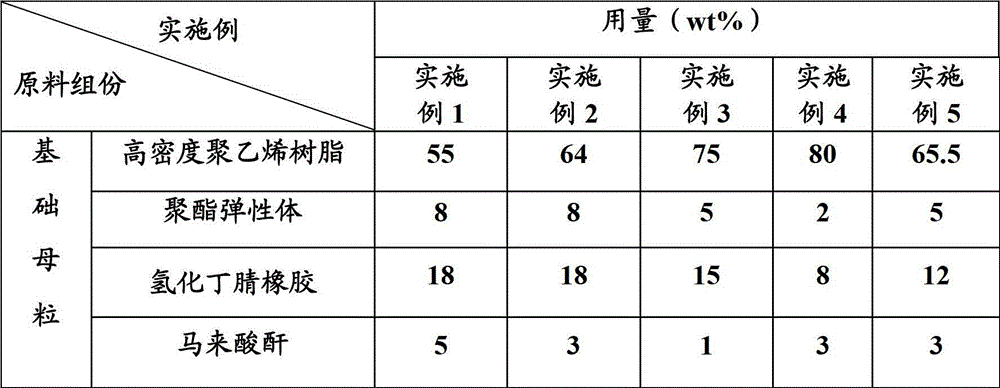

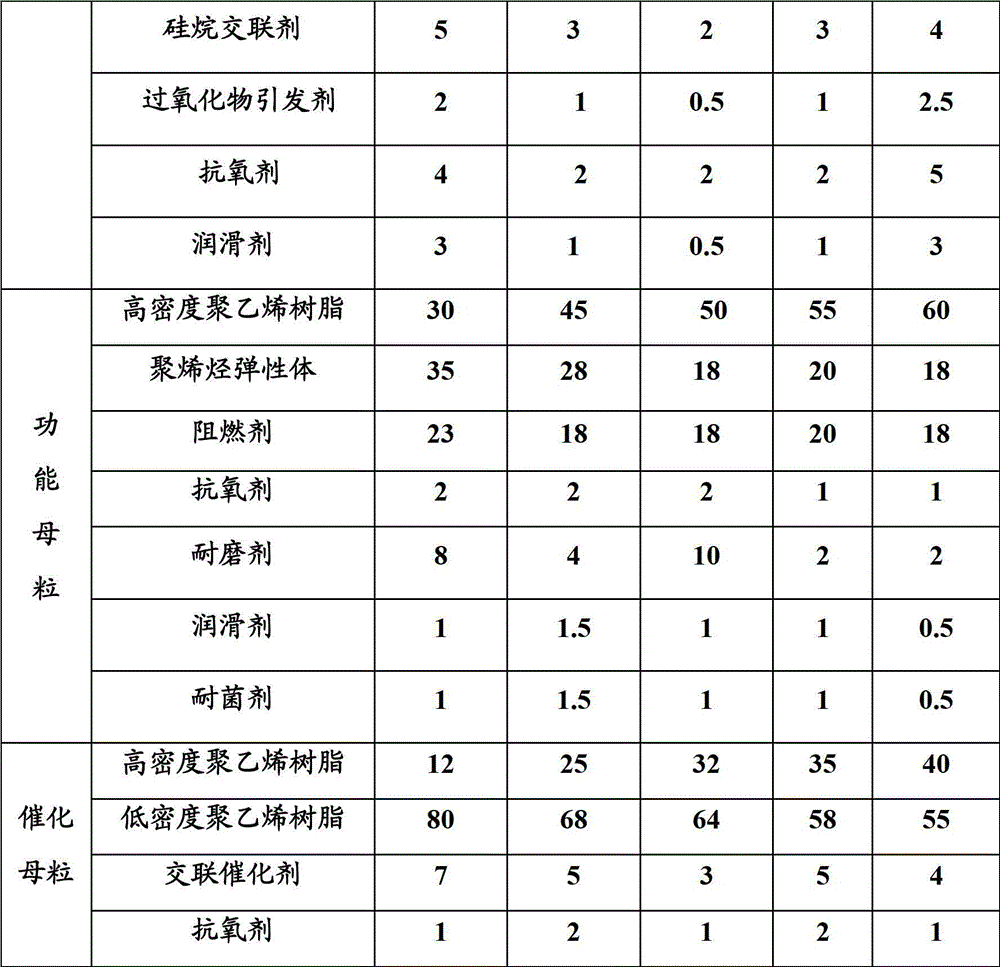

[0030] This embodiment provides a high temperature resistant silane crosslinked insulating flame retardant material, its raw material formula is shown in Table 1, wherein:

[0031] The weight ratio of basic masterbatch, functional masterbatch and catalytic masterbatch is 100:25:5;

[0032] The melt index of high-density polyolefin resin is 0.3g / 10min; the melt index of low-density polyolefin resin is 4g / 10min;

[0033] Peroxide initiator is dicumyl peroxide; silane crosslinking agent is vinyltrimethoxysilane; antioxidant is antioxidant 1010 and antioxidant DLTP; flame retardant is zinc stannate, antimony trioxide and brominated flame retardant in a weight ratio of 1:0.25:0.5; the lubricant is a combination of microcrystalline paraffin and polyethylene wax (the weight content of microcrystalline paraffin is 60%); the antibacterial agent is vanillin; crosslinking The catalyst is dibutyltin dilaurate.

[0034] The preparation method of high temperature resistant silane crosslin...

Embodiment 2

[0040] This embodiment provides a high temperature resistant silane crosslinked insulating flame retardant material, its raw material formula is shown in Table 1, wherein:

[0041] The weight ratio of basic masterbatch, functional masterbatch and catalytic masterbatch is 100:30:8;

[0042] The melt index of high-density polyolefin resin is 1g / 10min; the melt index of low-density polyolefin resin is 4g / 10min;

[0043] The peroxide initiator is dicumyl peroxide; the silane crosslinking agent is vinyltrimethoxysilane; the antioxidant is antioxidant 1010 and antioxidant 1024; the flame retardant is zinc stannate, antimony trioxide and brominated flame retardant in a weight ratio of 1:0.8:1.5; the lubricant is a combination of microcrystalline paraffin and polyethylene wax (the weight content of microcrystalline paraffin is 80%); the antibacterial agent is vanillin; crosslinking The catalyst is dibutyltin dilaurate.

Embodiment 3

[0045] This embodiment provides a high temperature resistant silane crosslinked insulating flame retardant material, its raw material formula is shown in Table 1, wherein:

[0046] The weight ratio of basic masterbatch, functional masterbatch and catalytic masterbatch is 100:40:8;

[0047] The melt index of high-density polyolefin resin is 0.3g / 10min; the melt index of low-density polyolefin resin is 5g / 10min;

[0048] The peroxide initiator is dicumyl peroxide; the silane crosslinking agent is vinyltriethoxysilane; the antioxidant is antioxidant 1010 and antioxidant 1024; the flame retardant is zinc stannate, trioxide Antimony and bromine flame retardants are composed of a weight ratio of 1:0.6:1.2; the lubricant is a combination of microcrystalline paraffin and polyethylene wax (wherein the weight content of microcrystalline paraffin is 80%); the antibacterial agent is vanillin; The joint catalyst is stannous octoate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com