Special PVDC coating latex for cigarette film and its preparation method and application

A technology for coating latex and cigarette film, which is applied in coating, transportation and packaging, flexible coverings, etc. It can solve the problems of unsatisfactory barrier properties, achieve good stability and maintain the effect of cigarette flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

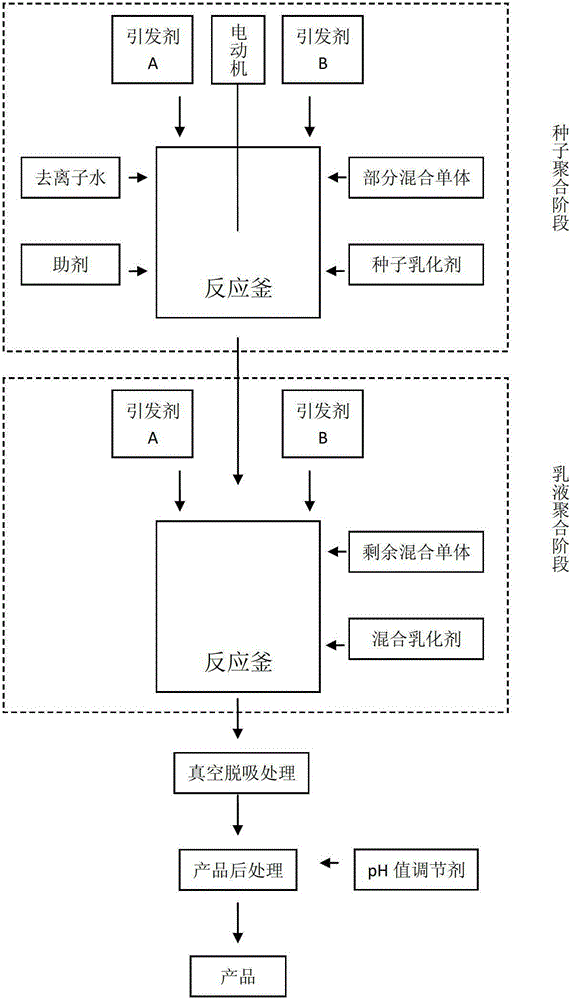

Method used

Image

Examples

Embodiment 1

[0034] PVDC latex for cigarette film, the total weight of the copolymerization system is 200kg, and the mixed monomer accounts for 100kg;

[0035] Vinylidene chloride 90kg;

[0036] Methyl acrylate 9.6kg;

[0037] Itaconic acid 0.4kg;

[0038] Additives: 48g of ammonium acetate and 1.6g of ferrous chloride;

[0039] Initiator: 80g of tert-butyl hydroperoxide and 80g of sodium formaldehyde sulfoxylate;

[0040] Emulsifier: sodium secondary alkane sulfonate 2kg;

[0041] Seed emulsifier: sodium secondary alkane sulfonate 80g;

[0042] The specific operation process is:

[0043] (1) Mixed monomer preparation: mix the vinylidene chloride and methyl acrylate, stir for 2 hours, and set aside;

[0044] (2) Preparation of emulsion polymerization emulsifier: dilute the sodium secondary alkane sulfonate with water to 10 parts, and set aside;

[0045] (3) Initiator preparation: Dilute the two initiators to a concentration of 2% by mass respectively, and set aside;

[0046] (4) Se...

Embodiment 2

[0056] PVDC latex for cigarette film, the total weight of the copolymerization system is 200kg, and the mixed monomer accounts for 100kg;

[0057] Vinylidene chloride 90.6kg;

[0058]Methyl acrylate 9.1kg;

[0059] Itaconic acid 0.3kg;

[0060] Additives: 72g of ammonium acetate and 2.4g of ferrous chloride;

[0061] Initiator: 160g of tert-butyl hydroperoxide and 160g of sodium formaldehyde sulfoxylate;

[0062] Emulsifier: sodium secondary alkane sulfonate 2.4kg;

[0063] Seed emulsifier: sodium paraffin sulfonate 100g;

[0064] The specific operation process is:

[0065] (1) Mixed monomer preparation: mix the vinylidene chloride and methyl acrylate, stir for 2 hours, and set aside;

[0066] (2) Preparation of emulsion polymerization emulsifier: dilute the sodium secondary alkane sulfonate with water to 10 parts, set aside;

[0067] (3) Initiator preparation: Dilute the two initiators to a concentration of 2% by mass respectively, and set aside;

[0068] (4) Seed pol...

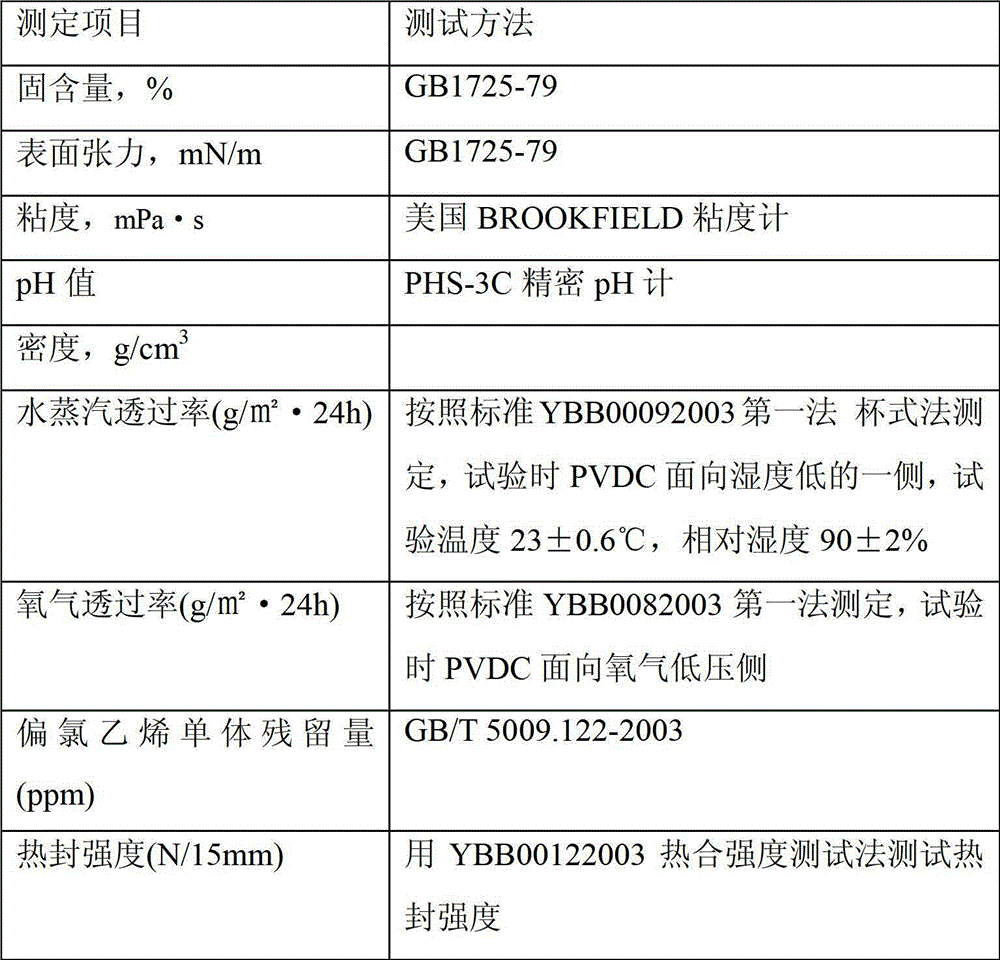

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com