Formula and preparation method for first-level waterproof glass molding injection bottle glass

An injection bottle, water resistance technology, applied in the field of medicinal glass infusion bottles, can solve problems such as glass melting and production difficulties, achieve low gas rate, avoid residues, and ensure the effect of melting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

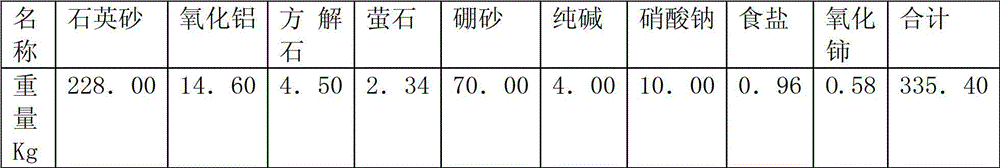

[0035] First-class water-resistant glass molded injection bottle glass formula, composed of the following raw materials:

[0036]

[0037] The first-class water-resistant glass molded injection bottle glass formula is composed of the following raw materials in mass fraction:

[0038]

[0039] M: represents the divalent alkaline earth metal Ca;

[0040] R: Na.

[0041] Production process: raw materials - batching - melting - feeding - bottle making - annealing - inspection and packaging - storage.

[0042] Before the batching, measure the water content of the raw materials, weigh various raw materials according to the batching recipe and transport them to the mixer, and mix for 210 seconds. The uniformity of the batching materials is ≥ 98%, and the moisture content is ≤ 2%.

[0043] Said melting: using a full-cooled top electric melting furnace, using molybdenum electrode melting part for electric heating, and silicon carbide rods for auxiliary heating in the feed chann...

Embodiment 2

[0049] First-class water-resistant glass molded injection bottle glass formula, composed of the following raw materials:

[0050]

[0051] The first-class water-resistant glass molded injection bottle glass formula is composed of the following raw materials in mass fraction:

[0052]

[0053]

[0054] M: represents the divalent alkaline earth metal Mg;

[0055] R:K.

[0056] Production process: raw materials - batching - melting - feeding - bottle making - annealing - inspection and packaging - storage.

[0057] Before the batching, measure the water content of the raw materials, weigh various raw materials according to the batching recipe and transport them to the mixer, and mix for 210 seconds. The uniformity of the batching materials is ≥ 98%, and the moisture content is ≤ 2%.

[0058] Said melting: using a full-cooled top electric melting furnace, using molybdenum electrode melting part for electric heating, and silicon carbide rods for auxiliary heating in the ...

Embodiment 3

[0064] With embodiment 1, wherein M: represents divalent alkaline earth metal Ba.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com