Offshore platform floating crane system with three-stage amplitude-changing and shock-absorbing hedging hydraulic device

A technology of offshore platforms and hydraulic devices, which is applied in the direction of spring/shock absorber, vibration suppression adjustment, mechanical equipment, etc., can solve the problems of the working field of the floating crane system and the load limit, and achieve the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Preferred embodiments of the present invention are described in detail as follows in conjunction with accompanying drawings:

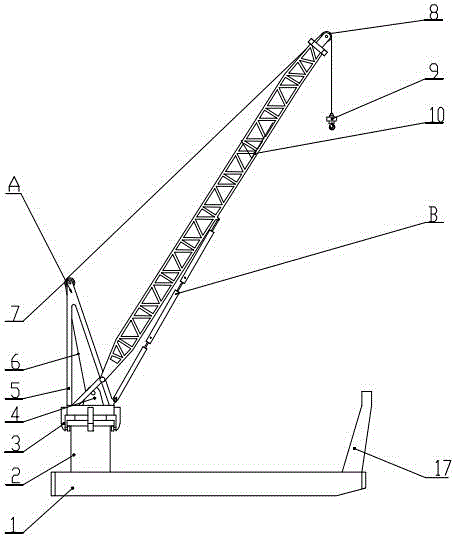

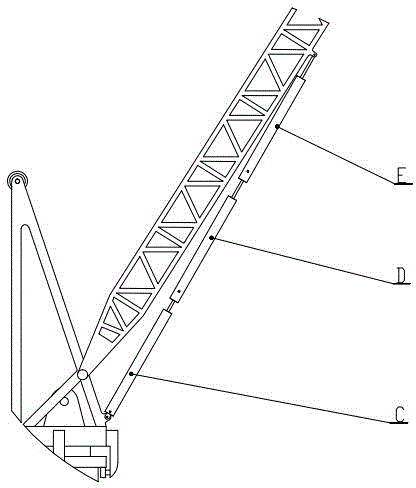

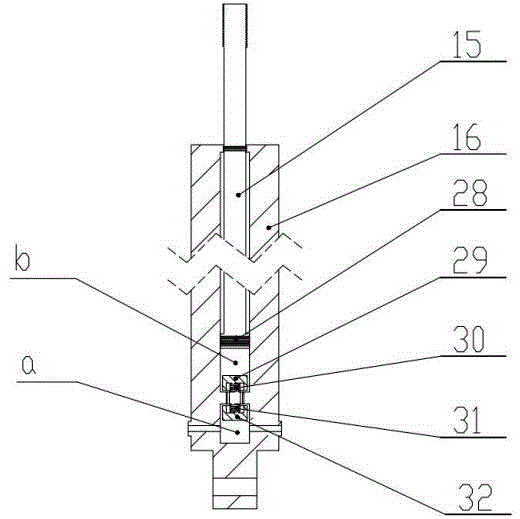

[0013] see figure 1 — Figure 5 , a new type of floating crane system for offshore platforms, a floating crane system for offshore platforms with three-stage amplitude-changing and shock-absorbing hedging hydraulic devices, including a hull 1, a shelf 17, a base 2, a slewing platform 3, A tower column 5, a set of main hoisting mechanism A, a pair of three-stage luffing and shock-absorbing hedging hydraulic mechanism B. The hull 1 is fixedly connected to the base 2; the slewing platform 3 and the pedestal 2 are connected through a rotating pair; the slewing platform 3 can rotate 360° around its axis; the tower column 5 is fixed on the slewing platform 3; a pair of three-stage luffing and The damping hydraulic mechanism B is connected to the tower column 5 and the jib frame 10 respectively through a rotating pair.

[0014] The structure of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com