Metal-doped carbon/sulfur compound, and preparation and application thereof

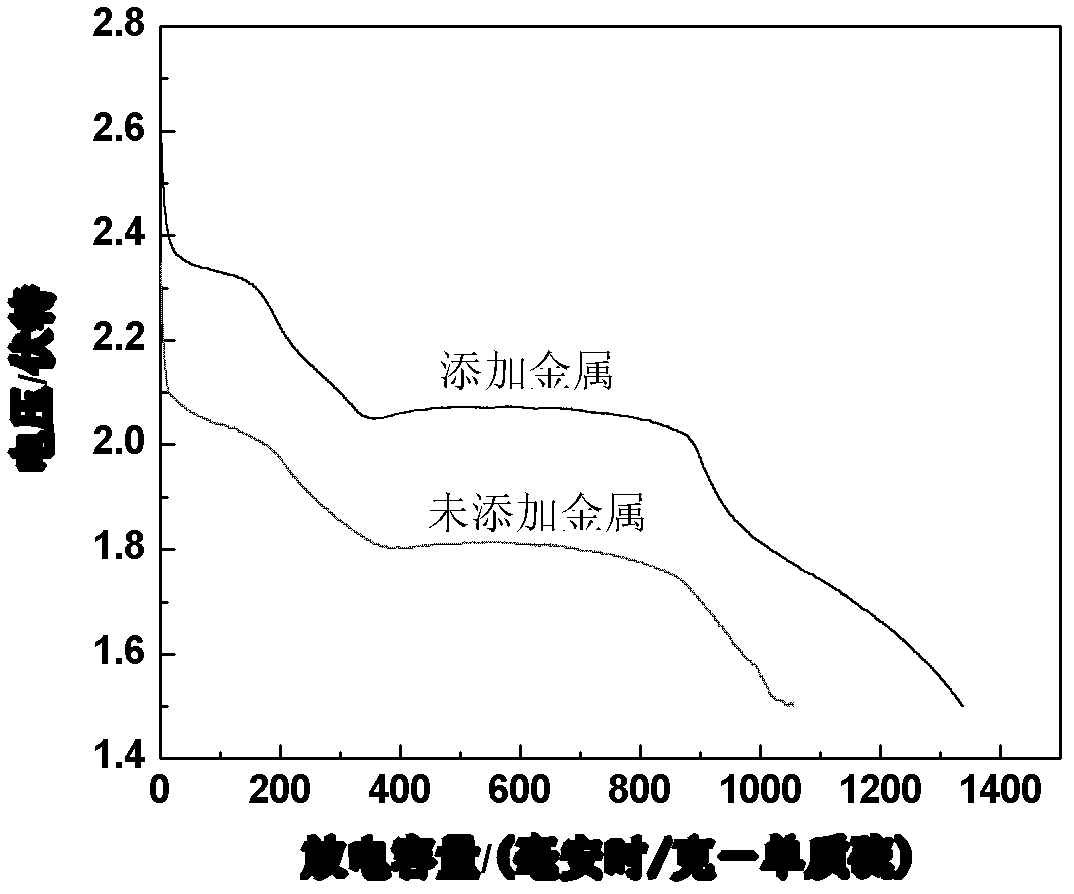

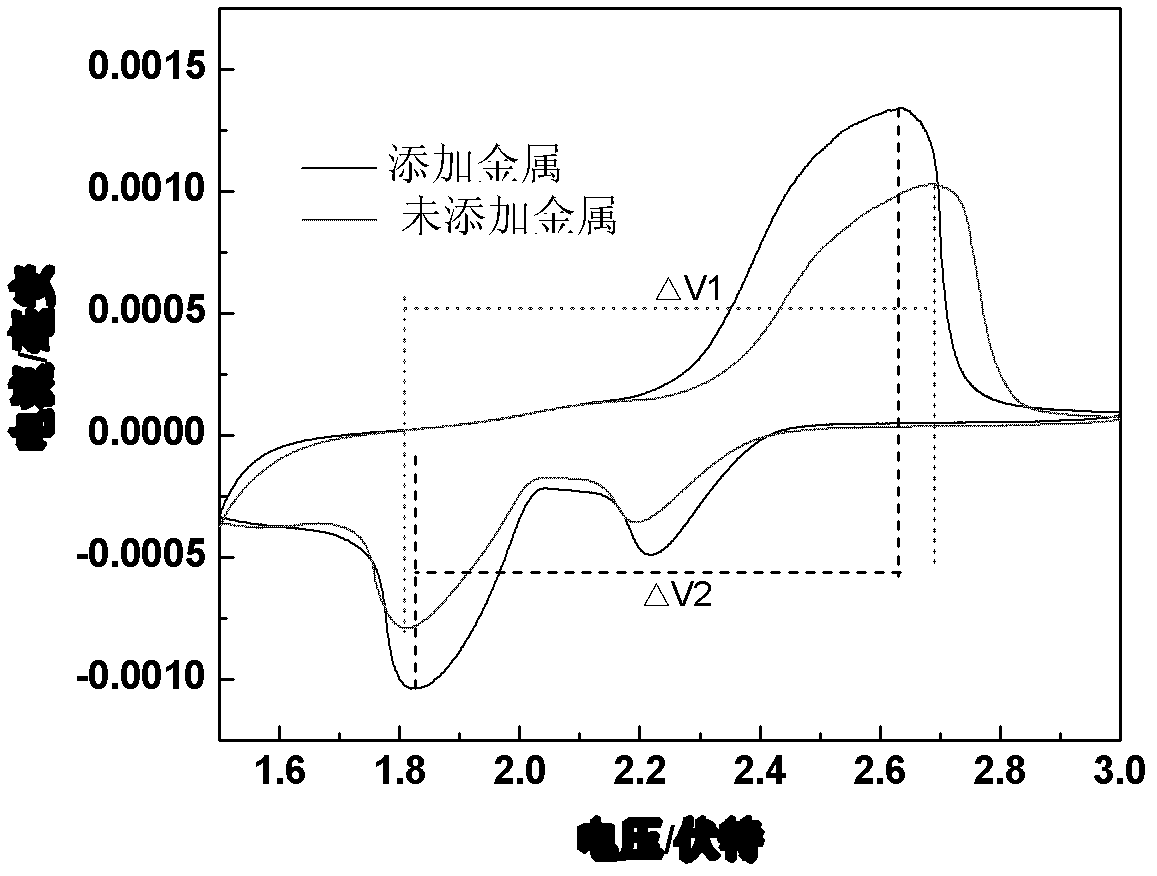

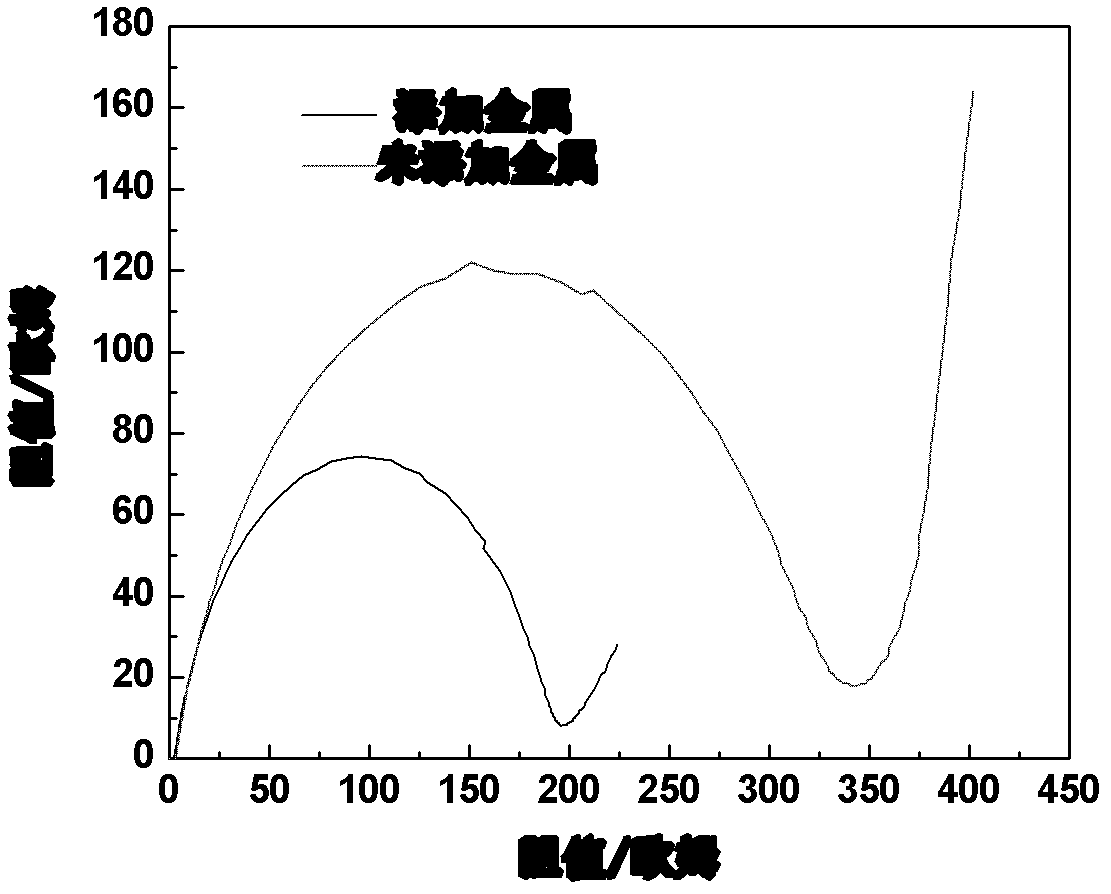

A technology of metal doping and composites, applied in electrical components, battery electrodes, circuits, etc., can solve problems affecting the discharge performance of lithium-sulfur batteries, unfavorable active material sulfur nanometerization, and restricting development, so as to improve cycle stability, The effect of low price and low product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Mix 1.0g of triblock copolymer (F127) and 5.0g of ethanol uniformly, add 1.0g of 0.2M dilute hydrochloric acid solution, stir at room temperature for 0.5h to fully dissolve and form transparent solution A; add 0.5g of Phenolic resin and 0.05g cobalt nitrate, continue to stir for 0.5h to form a uniform solution B; add 2g of magnesium oxide to solution B, continue to stir at room temperature for 3h to form solution C; spread solution C evenly on a glass plate , after volatilizing at room temperature for 3 hours, treat at 80°C for 12h to form a soft film D; heat treat film D at 300°C for 2 hours under inert gas protection conditions, and heat treat at 800°C for 1 hour under inert gas protection conditions to obtain solid powder E, wherein The heating rate is 1°C / min, soak solid powder E in 0.5M dilute acid solution for 24 hours, wash and dry to obtain black powder F; after mixing black powder F and elemental sulfur at a mass ratio of 1:1 , placed in a tube furnace, kept at...

Embodiment 2

[0038]After uniformly mixing 1.0g F127 and 20.0g ethanol, add 1.0g dilute hydrochloric acid solution, stir at room temperature for 3 hours to fully dissolve and form a transparent solution A; add 0.5g phenolic resin and 0.05g nickel nitrate solution to solution A, continue Stir for 0.5h to form a uniform solution B; add 2g of alumina to solution B, reflux and stir at 90°C for 8h to form solution C; apply solution C evenly on a glass plate, evaporate at room temperature for 12h, ℃ treatment for 48 hours to form a soft film D; the film D was heat-treated at 400 ℃ for 6 hours under inert gas protection conditions, and 1200 ℃ for 5 hours under inert gas protection conditions to obtain solid powder E, wherein the heating rate was 10 ℃ / min, Soak solid powder E in 5M dilute acid solution for 50 hours, wash and dry to obtain black powder F; mix black powder F and elemental sulfur uniformly at a mass ratio of 1:5, place in a tube furnace, vacuum The temperature is -0.03MPa, 160°C for 1...

Embodiment 3

[0040] After uniformly mixing 1.0g F127 and 10.0g ethanol, add 1.0g dilute hydrochloric acid solution, stir at room temperature for 1 hour to fully dissolve and form a transparent solution A; add 1.0g phenolic resin and 0.1g copper acetate to solution A, and continue stirring 0.5h to form a uniform solution B; add 2g calcium carbonate to solution B, stir at 40°C for 4.5h to form solution C; apply solution C evenly on a glass plate, evaporate at room temperature for 12h, Treat for 24 hours to form a soft film D; heat treat the film D at 350°C for 3 hours under inert gas protection conditions, and heat treat at 900°C for 2 hours under inert gas protection conditions to obtain solid powder E, wherein the heating rate is 5°C / min. Soak solid powder E in 2M dilute hydrochloric acid solution for 50 hours, wash and dry to obtain black powder F; mix black powder F and elemental sulfur evenly in a mass ratio of 1:4, place in a tube furnace, vacuum It was kept at -0.1MPa and 150°C for 5h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com