Multilayer ceramic capacitor and preparation method thereof

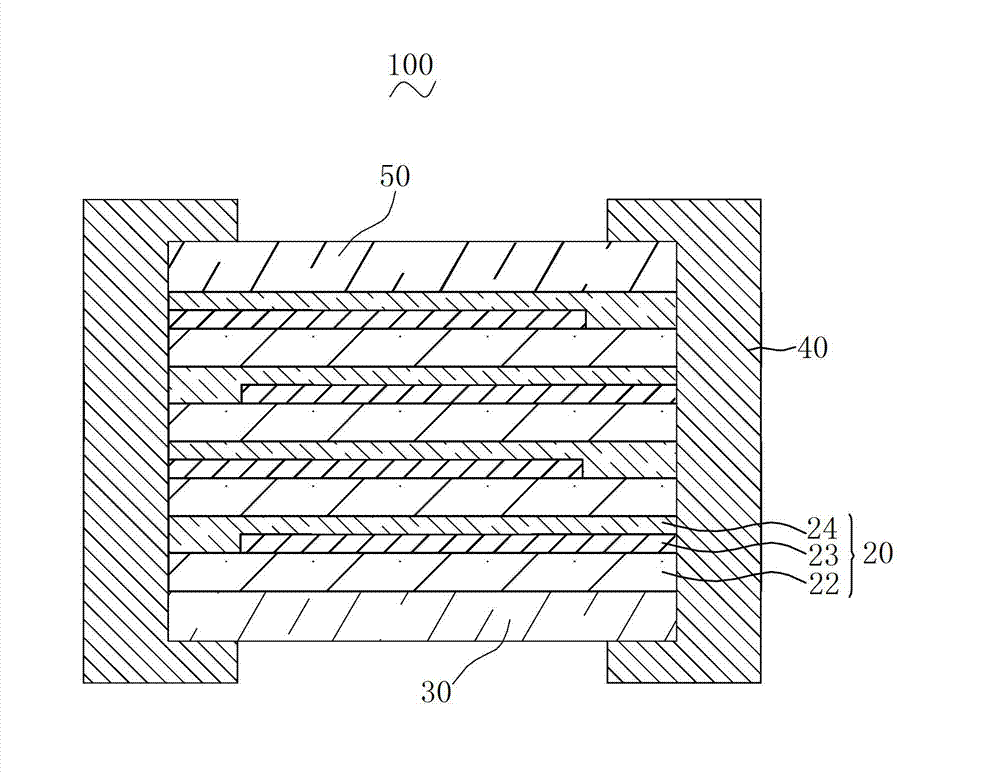

A technology of multilayer ceramics and capacitors, applied in the direction of multilayer capacitors, fixed capacitor electrodes, fixed capacitor dielectrics, etc., can solve the short circuit of the inner electrode layer, reduce the contact area of the ceramic dielectric layer, and reduce the facing between the inner electrode layers. Area and other issues, to eliminate height differences and voids, ensure the facing area, and achieve the effect of high effective capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

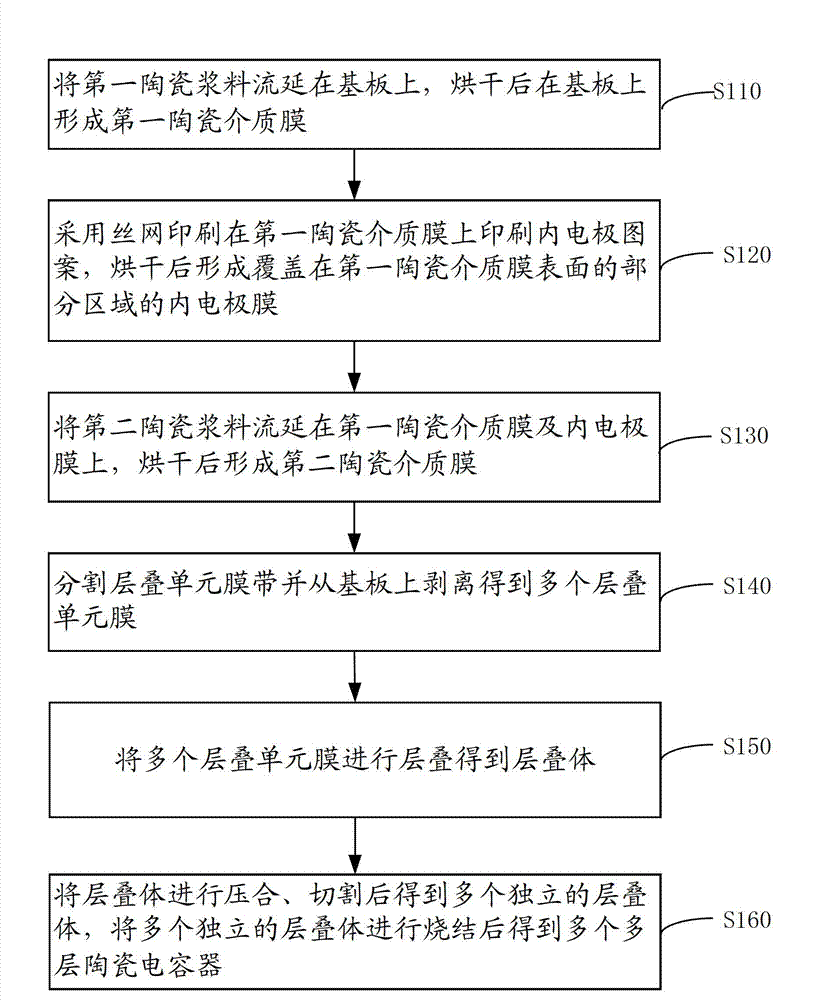

[0046] see image 3 , the preparation method of the multilayer ceramic capacitor of an embodiment, comprises the steps:

[0047] Step S110: casting the first ceramic slurry on the substrate, and forming a first ceramic dielectric film on the substrate after drying.

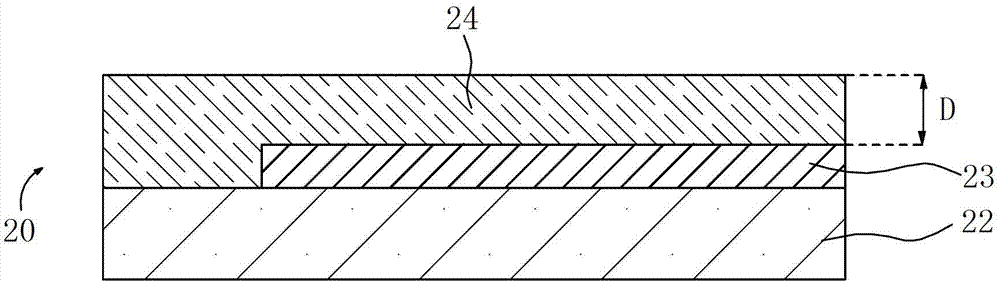

[0048] Please also refer to FIG. 4( a ), the substrate 210 is a polyethylene terephthalate (PET) substrate, so as to facilitate subsequent peeling and avoid damage to the first ceramic dielectric film 220 during peeling.

[0049] The first ceramic slurry includes 45-50% by mass of ceramic powder, 15-20% by mass of organic binder and 30-40% by mass of solvent.

[0050] The main component of the ceramic powder is preferably barium titanate, the organic binder is preferably polyvinyl butyral, the solvent is preferably a mixture of toluene and ethanol, and the mass ratio of toluene and ethanol is 1:1~4:1.

[0051] The ceramic powder, the organic binder and the solvent are mixed according to the above mass percentage...

Embodiment 1

[0089] 1. Mix 45% by mass of ceramic powder, 15% by mass of organic binder and 40% by mass of solvent to obtain a first ceramic slurry with a viscosity of 300 cps. Among them, the main component of the ceramic powder is barium titanate, the organic binder is polyvinyl butyral, and the solvent is a mixture of toluene and ethanol at a mass ratio of 1:1. Casting and coating the first ceramic slurry on the PET substrate with a tape casting machine to form a first ceramic slurry layer, and then drying at 60° C. to form a first ceramic dielectric film with a thickness of 0.8 microns;

[0090] 2. Print the internal electrode layer pattern on the above-mentioned first ceramic dielectric film by screen printing, and then dry it at 70°C to form an internal electrode film with a thickness of 1 micron covering a part of the surface of the first ceramic dielectric film And the alignment mark, the inner electrode film is nickel electrode film;

[0091] 3. Mix 45% by mass of ceramic powder,...

Embodiment 2

[0098] 1. Mix 50% by mass of ceramic powder, 20% by mass of organic binder and 30% by mass of solvent to obtain a first ceramic slurry with a viscosity of 450 cps. Among them, the main component of the ceramic powder is barium titanate, the organic binder is polyvinyl butyral, and the solvent is a mixture of toluene and ethanol at a mass ratio of 4:1. Casting and coating the first ceramic slurry on the PET substrate with a tape casting machine to form a first ceramic slurry layer, and then drying at 70° C. to form a first ceramic dielectric film with a thickness of 4 microns;

[0099] 2. Print the internal electrode layer pattern on the above-mentioned first ceramic dielectric film by screen printing, and then dry it at 80°C to form an internal electrode film with a thickness of 1.5 microns covering a part of the surface of the first ceramic dielectric film And the alignment mark, the inner electrode film is nickel electrode film;

[0100] 3. Mix 50% by mass of ceramic powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com