Abrasion-resistant composite material and preparation method thereof

A composite material, plastic resin technology, applied in the field of polymer material modification, to achieve the effect of good effect, high hardness and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 0.05 parts of KH550 and 0.05 parts of NDZ-102 to 100 parts by weight of PP and mix them at room temperature with a high-speed mixer, and then mix 2.5 parts of B with a particle size of 1500 mesh 4 C. Add 2.5 parts of PTFE with a particle size of 1500 meshes for high-speed mixing at room temperature, and finally add 0.1 parts of silicone powder for high-speed mixing at room temperature. The mixing speed is 100 rpm throughout the mixing process, and the mixing time is 2 minutes. The blend is extruded and granulated by a twin-screw extruder. The temperature of each zone of the extruder from the feeding section to the head temperature is 140°C, 160°C, 160°C, 170°C, 170°C, 180°C, 180°C ℃, 190℃, 190℃, 195℃, the length-to-diameter ratio of the extrusion screw is 30, and the rotation speed of the extrusion screw is 150 rpm; the single-screw injection molding temperature is 180℃, 200℃, 200℃ from the feed to the machine head , 200°C, 210°C, the aspect ratio of the screw of th...

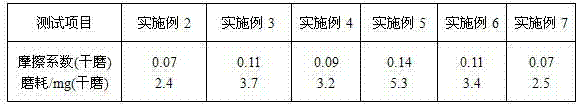

Embodiment 2

[0037] Add 2 parts of DL-411 to 100 parts by weight of PP and mix it with a high-speed mixer at room temperature, and then mix 20 parts of B with a particle size of 2500 mesh 4 C. Add 10 parts of PTFE with a particle size of 5000 meshes for high-speed mixing at room temperature, and finally add 1 part of silicone powder and 1 part of EBS for high-speed mixing at room temperature. The mixing speed during the entire mixing process is 300 rpm. The mixing time is The mixed blend was extruded and granulated through a twin-screw extruder in 8 minutes. The temperature of each zone of the extruder from the feeding section to the head temperature was 140°C, 160°C, 170°C, 180°C, 190°C, 200°C, 200°C, 210°C, 210°C, 215°C, the length-to-diameter ratio of the extrusion screw is 40, and the rotation speed of the extrusion screw is 350 rpm; the single-screw injection molding temperature is 180°C, 200 ℃, 220℃, 220℃, 230℃, the aspect ratio of the screw of the injection molding machine is 40, th...

Embodiment 3

[0040] Add 1 part of KH550 to 100 parts by weight of PET and mix it with a high-speed mixer at room temperature, and then mix 15 parts of B with a particle size of 5000 mesh 4C. Add 5 parts of PTFE with a particle size of 5000 meshes for high-speed mixing at room temperature, and finally add 0.5 parts of silicone powder and 1 part of EBS for high-speed mixing at room temperature. The mixing speed during the entire mixing process is 250 rpm. The mixing time is After 4 minutes, the mixed blend was extruded and granulated through a twin-screw extruder. The temperature of each zone of the extruder from the feeding section to the head temperature was 240°C, 260°C, 270°C, 280°C, 290°C, 290°C, 290°C, 290°C, 290°C, 295°C, the length-to-diameter ratio of the extrusion screw is 35, and the rotation speed of the extrusion screw is 300 rpm; ℃, 290℃, 300℃, 300℃, the aspect ratio of the screw of the injection molding machine is 35, the screw speed is 300 rpm, the injection pressure is 60MPa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Abrasion | aaaaa | aaaaa |

| Abrasion | aaaaa | aaaaa |

| Abrasion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com