Method for desulfurization and denitrification of fume and coproduction of ammonium sulfate

An ammonium sulfate and flue gas technology, which is applied in the field of flue gas purification, can solve the problems of oxidation failure of ferrous complexing agents and other problems, and achieve the effect of significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

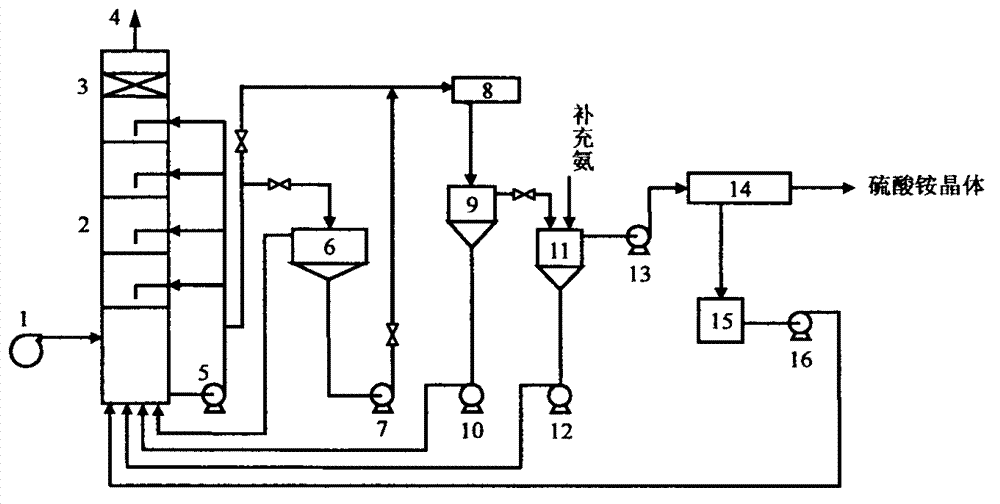

Image

Examples

Embodiment 1

[0025] A coal-fired boiler with a rated evaporation capacity of 75t / h and a flue gas volume of 100,000 Nm 3 / h, SO 2 The content is 1500mg / Nm 3 , NO content is 600mg / Nm 3 , the flue gas temperature is 135°C, according to the method of the present invention, the SO 2 Content 90mg / Nm 3 , NO content 60mg / Nm 3 , The desulfurization rate is 94%, and the denitrification rate is 90%.

[0026] Prepare a complexing agent solution with a concentration of 18mmol / L with equimolar ferrous sulfate and disodium edetate, and add coal powder with a particle size of 100-400 μm to make the slurry solid content 15%.

[0027] The absorption tower is a spray tower with a diameter of 4m and a height of 25m.

[0028] Absorption tower operating liquid gas ratio is 10L / Nm 3 , slurry flow rate 1000m 3 / h, the bottom of the absorption tower is used as a circulation pool, the residence time of the slurry in the circulation pool is 10min, and the pH value of the slurry is 3-4.

[0029] SO removal ...

Embodiment 2

[0031] A coal-fired boiler with a rated evaporation capacity of 150t / h and a flue gas volume of 198,000 Nm 3 / h, SO 2 Content 1500mg / m 3 , NO content 500mg / Nm 3 , the flue gas temperature is 120°C, according to the method of the present invention, the SO 2 Content 90mg / Nm 3 , NO content 40mg / Nm 3 , The desulfurization rate is 94%, and the denitrification rate is 92%.

[0032] The absorption tower is a spray tower with a diameter of 5.5m and a height of 29m.

[0033] Prepare a complexing agent solution with a concentration of 18mmol / L by equimolar ferrous sulfate and disodium edetate, and add mineral pyrite powder with a particle size of 200-600 μm to make the slurry solid content 20%.

[0034] Absorber operating liquid-gas ratio is 12L / Nm 3 , slurry flow rate 2376m 3 / h, the bottom of the absorption tower is used as a circulation pool, the residence time of the slurry in the circulation pool is 10min, and the pH value of the slurry is 3-4.

[0035] SO removal from flu...

Embodiment 3

[0037] A coal-fired boiler with a rated evaporation capacity of 130t / h and a flue gas volume of 170,000 Nm 3 / h, SO 2 Content 1500mg / Nm 3 , NO content 400mg / Nm 3 , the flue gas temperature is 130°C, according to the method of the present invention, the SO 2 Content 90mg / Nm 3 , NO content 40mg / Nm 3 , The desulfurization rate is 94%, and the denitrification rate is 90%.

[0038] The slurry is prepared with disodium edetate and coal powder with a particle size of 300-600 μm, the concentration of disodium edetate is 15 mmol / L, and the solid content is 18%. During the washing process, sulfur dioxide and oxygen leach coal-based pyrite to generate ferrous iron, which reacts with disodium edetate to generate ferrous complexing agent.

[0039] The absorption tower is a swirl plate tower with a diameter of 5m and a height of 25m.

[0040] Absorption tower operating liquid gas ratio is 10L / Nm 3 , slurry flow rate 1700m 3 / h, the bottom of the absorption tower is used as a circul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com