Non-linear associating water-soluble quadripolymer, and preparation and use thereof

A quaternary copolymer and water-soluble technology, which is applied in the field of nonlinear associative water-soluble tetrapolymer and its preparation, and can solve the problems of easy plugging of pore throats and large hydrodynamic radius of comb polymers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 20.000 grams of acrylamide, 16.320 grams of 2-acrylamido-2-methylpropanesulfonic acid, 9.180 grams of allyl octylphenol polyoxyethylene ether (the adduct EO of polyoxyethylene ether is 20), 3, 4.370 grams of 5-bis(trifluoromethyl)styrene and 8.020 grams of sodium lauryl sulfate were dissolved in 186 milliliters of distilled water, added in a three-necked reaction flask, and the pH of the solution was adjusted to 5 with NaOH, the reaction temperature was 60°C, and N 2 After 30 minutes, add 10.50 mL of 0.05 mol / L potassium persulfate initiator solution, react for 24 hours, and dilute the polymer with water to obtain a PACH concentrated solution.

Embodiment 2

[0040] 20.000 grams of acrylamide, 3.220 grams of vinylbenzenesulfonic acid, 5.700 grams of 4-vinylbenzylnonylphenol polyoxyethylene ether (EO is 10), 1.526 grams of 4-butylstyrene and sodium lauryl sulfate 10.020 g was dissolved in 410 ml deionized water, adjusted to pH=7 with NaOH, the reaction temperature was 55°C, and N 2 After 30 minutes, add 4.73 mL of 0.05 mol / L ammonium persulfate initiator solution and react for 8 hours. The polymer was dissolved in water to prepare a concentrated solution of PACH.

Embodiment 3

[0042] Dissolve 20.000 grams of acrylamide, 12.500 grams of acrylic acid, 15.600 grams of allyl cetyl polyoxyethylene ether (EO is 30), 7.850 grams of p-hexylphenylstyrene and 35.600 grams of sodium lauryl sulfate in 850 ml Deionized water, adjust pH=4 with NaOH, reaction temperature 75°C, pass N 2 After 30 minutes, add 16.801 mL of 0.05 mol / L potassium persulfate initiator solution, and react for 24 hours. The polymer was dissolved in water to prepare a concentrated solution of PACH.

PUM

| Property | Measurement | Unit |

|---|---|---|

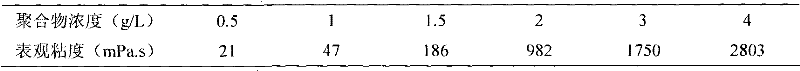

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com