Printed circuit board and formation method thereof

A printed circuit board and circuit technology, applied in the directions of printed circuits, printed circuit manufacturing, printed circuit components, etc., can solve the problems of complex milling methods, increase process costs, and complex process flows, and achieve reduction in process costs and avoidance. Corrosion damage, the effect of improving process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In the prior art, when performing an electroplating process on a printed circuit board, it is necessary to electrically connect the circuit to an external power source through a lead wire, so that the current is transmitted from the external power source to the circuit to achieve the purpose of electroplating metal. However, the processes of forming the lead wires and removing the lead wires are relatively complicated, which increases the process cost, and the process flow is complicated and the efficiency is low.

[0045] In order to solve the above problems, the present invention provides a printed circuit board, comprising:

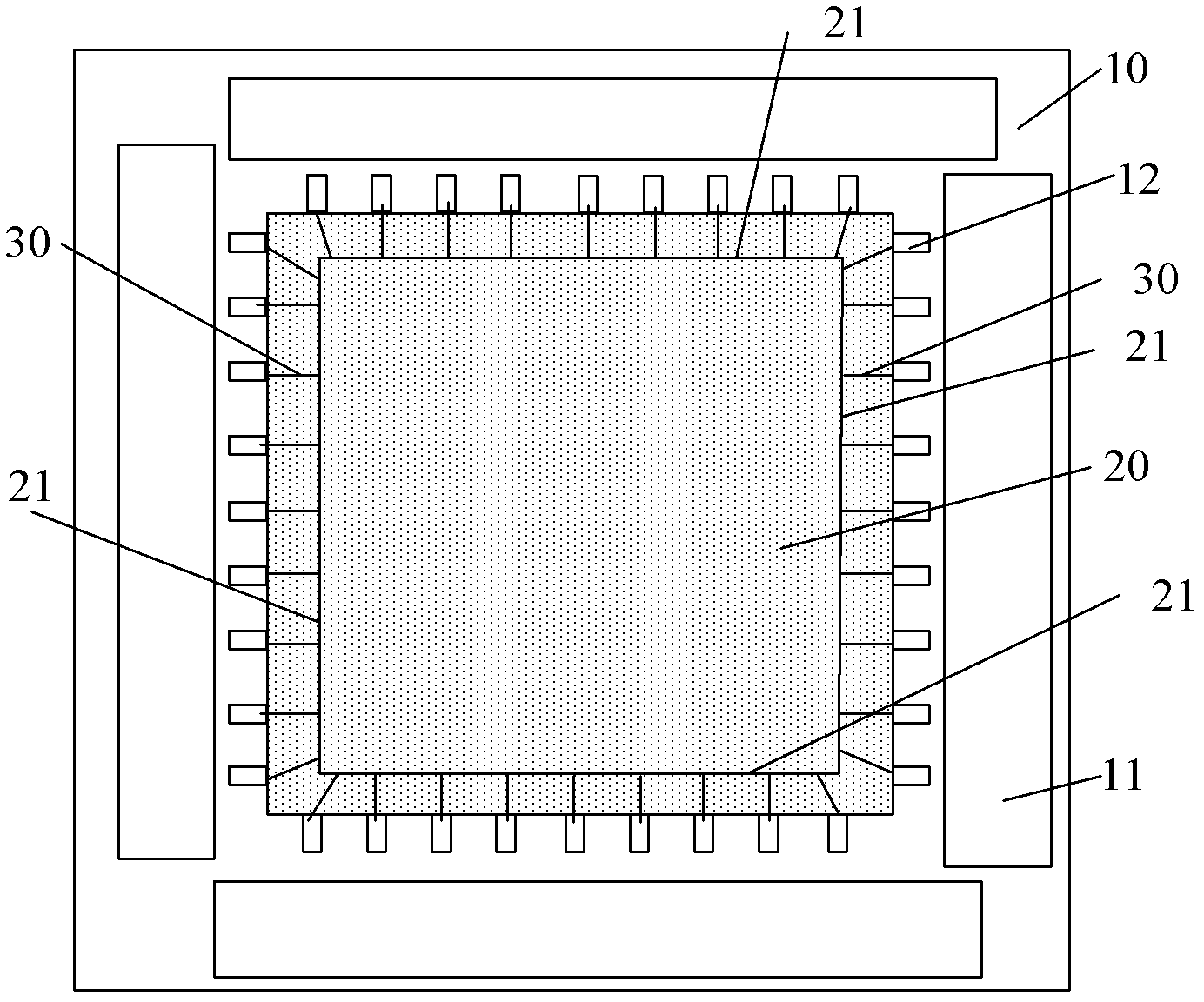

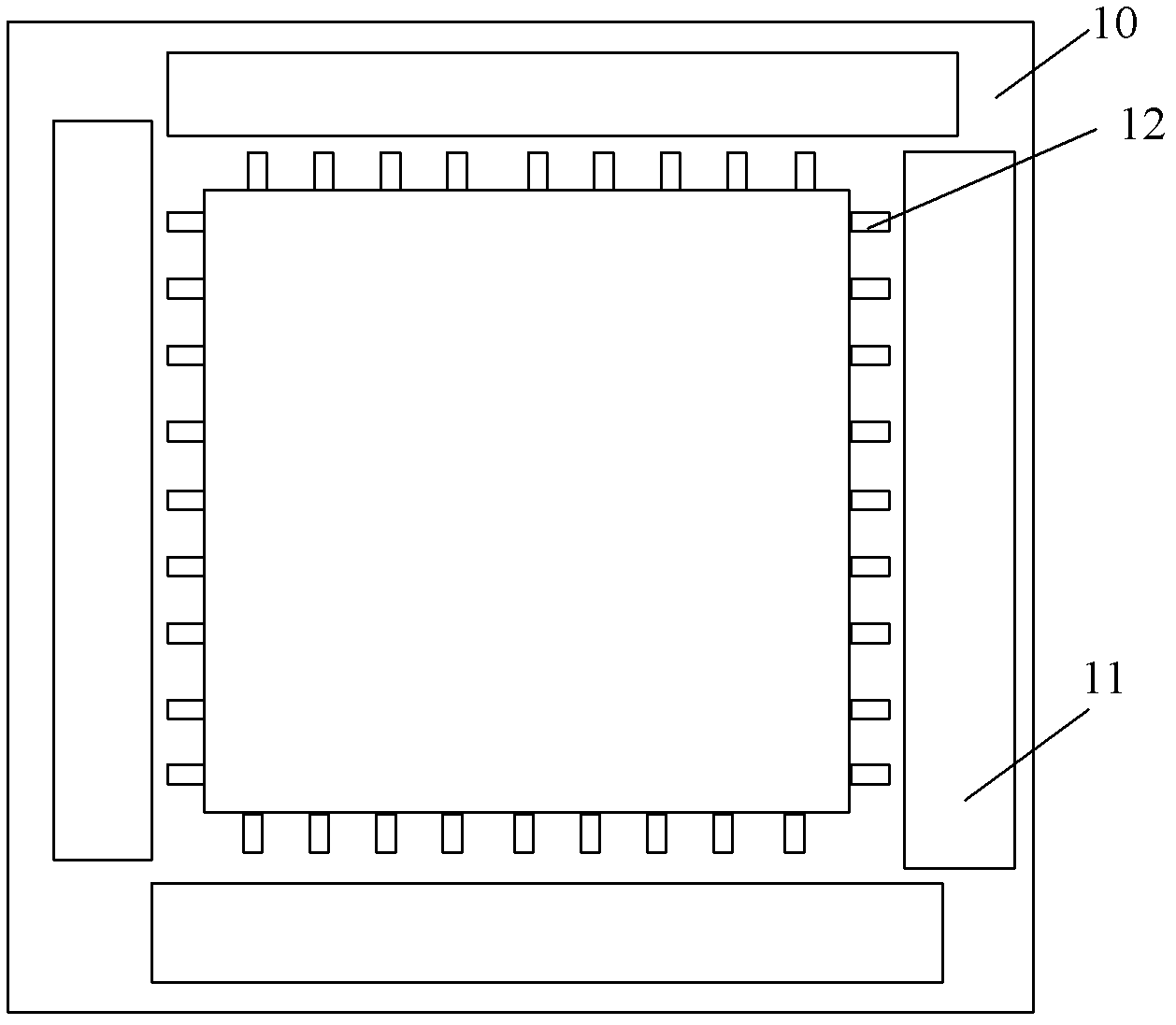

[0046] a substrate, on which a first region and a second region are formed, and the first region is arranged around the second region;

[0047] Lines are arranged in the first area, and a conductive area is formed in the second area;

[0048] Wherein, all the lines in the first area are connected to the conductive area, and are in a state of fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com