Surface low-temperature passivation method for solar battery

A solar cell and low-temperature technology, applied in circuits, electrical components, sustainable manufacturing/processing, etc., can solve the problems of difficult access to the medium, damage to the original structure of the solar cell, and inability to completely cover the surface of the cell, and achieve the adjustment of the refractive index, The effect of avoiding destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

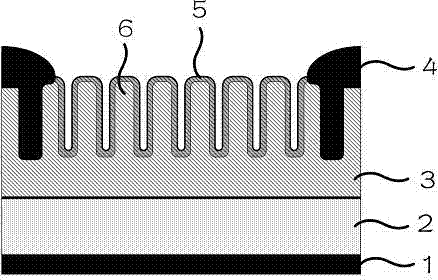

[0031] The prototype sample of the nano-surface silicon solar cell with the nanostructure 6 that has been prepared is placed in the autoclave, and 20 atmospheres of pure oxygen O are introduced into the autoclave. 2 ; Then heat the sealed autoclave to 400°C, at this time the air pressure in the autoclave increases to 4.3×106 Pa, and the sample continues to be heated for 25 minutes under this condition.

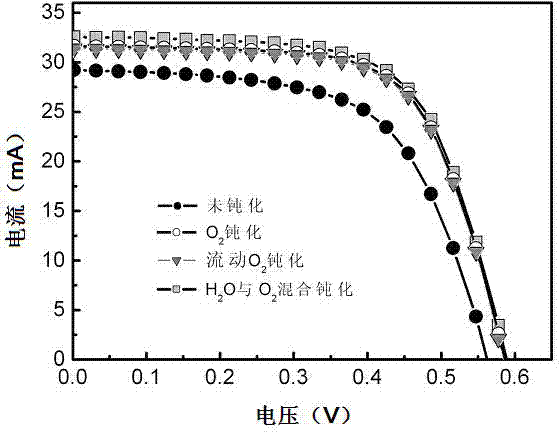

[0032] Such as figure 1 The sample after passivation by this method is shown as the method to prepare the metal lower electrode 1 and the metal upper electrode 4, and the solar cell efficiency test system is used to test the nano-surface silicon solar cells before and after passivation, and the test results It shows that the efficiency of nano-surface silicon solar cells increases from 10.6% without passivation to 12.2% after passivation, and the short-circuit current and fill factor are significantly improved. I-V reference measured by efficiency test system figure 2 , Qu...

Embodiment 2

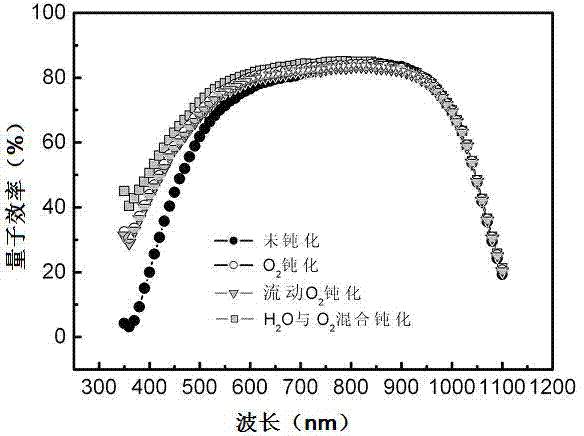

[0034] The prototype sample of the nano-surface silicon solar cell with nanostructure 6 that has been prepared is placed in the high-pressure reactor; the air inlet of the sealed reactor is continuously fed with pure oxygen O2 flowing at 40 atmospheres and 400 ° C to adjust the reaction. The air output from the outlet of the reactor maintained the internal pressure of the reactor at 40 atmospheres; the internal temperature of the reactor was maintained at 400°C; the sample continued to be heated under this condition for 25 minutes. The test results show that the efficiency of nano-surface silicon solar cells increases from 10.6% without passivation to 12.1% after passivation, and the short-circuit current and fill factor are significantly improved. I-V reference measured by efficiency test system figure 2 , Quantum efficiency test reference before and after passivation image 3 .

[0035]

Embodiment 3

[0037] Put the prepared prototype sample of the nano-surface silicon solar cell with nanostructure 6 into the autoclave, and add 1 ml of water into the autoclave;

[0038] 10 atmospheres of pure oxygen O was introduced into the autoclave 2 ; Then heat the sealed autoclave to 300°C, at this time the pressure of the autoclave increases and is controlled at 4.0×106 Pa, and the sample continues to be heated for 25 minutes under this condition.

[0039] The test results show that the efficiency of nano-surface silicon solar cells increases from 10.6% without passivation to 12.8% after passivation, and the short-circuit current and fill factor are significantly improved. I-V reference measured by efficiency test system figure 2 , Quantum efficiency test reference before and after passivation image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com