Method for producing suspension polymerization toner with densely charged core-shell structure

A technology of suspension polymerization and core-shell structure, which is applied in the field of toner manufacturing, can solve the problem of difficult toner particles, and achieve the effect of regular shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

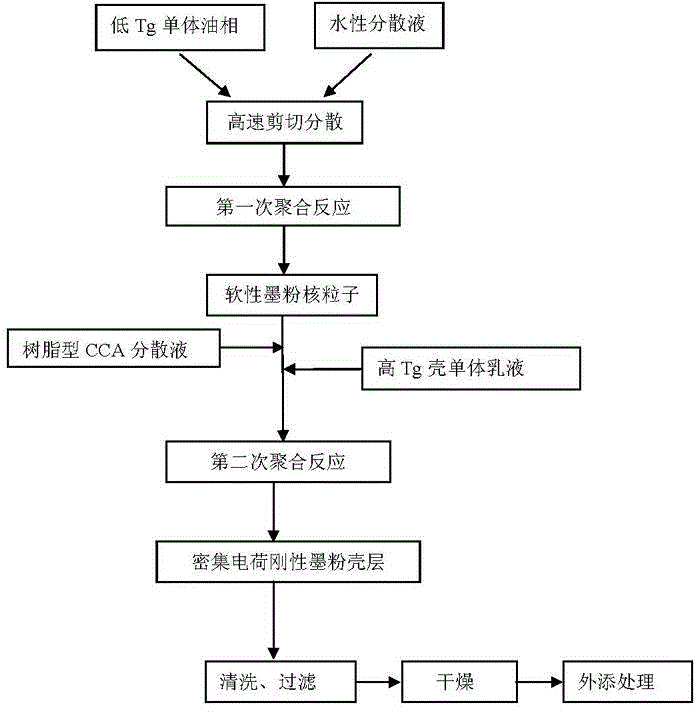

[0023] See figure 1 The preparation method of the suspension polymerization toner with densely charged core-shell structure provided by the present invention includes the following steps:

[0024] (1) Separately preparing a low-Tg monomer oil phase constituting the toner core particles and an aqueous dispersion for dispersing the low-Tg monomer oil phase;

[0025] (2) The above-mentioned monomer oil phase and the aqueous dispersion are blended at a certain oil-water ratio, and after high-speed shear suspension granulation, they are transferred to the reactor, and then the monomer oil phase is subjected to the first polymerization reaction (heating polymerization reaction). The body oil droplet particles are completely converted into polymer particles to obtain soft toner core particles;

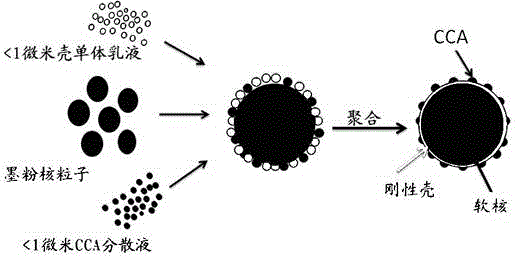

[0026] (3) The high Tg shell monomer constituting the rigid shell layer is added to water containing a certain amount of surfactant, and after high-speed shearing or ultrasound is used to form a min...

Embodiment 1

[0071] 81 parts of styrene, 19 parts of n-butyl acrylate, 0.3 parts of divinylbenzene, 1.0 part of n-dodecanethiol, 7 parts of carbon black (NP60, manufactured by Degussa), ester wax (WE-5 , Manufactured by Nippon Oil & Fat Co., Ltd.) 8 parts, the above components were dispersed in a bead mill at room temperature to prepare a monomer oil phase. Further add 6 parts of oil-soluble initiator 2-ethyl tert-butyl peroxyacetate and fully disperse for 30 minutes.

[0072] In addition, an aqueous solution of 100 parts of deionized water dissolved in 13 parts of magnesium chloride was slowly added to an aqueous solution of 200 parts of deionized water dissolved in 8.3 parts of sodium hydroxide, high-speed shear dispersion for 1 hour, and ultrasonic aging at room temperature for 4 hours to obtain magnesium hydroxide Suspension dispersion, in which the remaining electrolyte magnesium chloride concentration is 1wt% of water.

[0073] The prepared monomer oil phase was added to the magnesium hy...

Embodiment 2

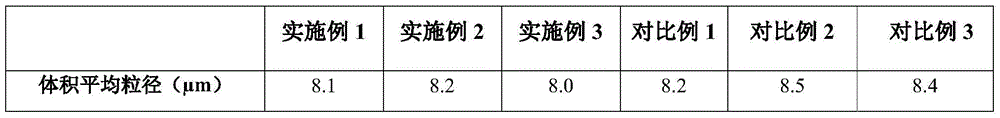

[0077] In addition to 10 parts of styrene, 0.3 parts of 1,4-butanediol dimethacrylate, and 20 parts of positive CCAFCA-201-PS (50nm, solid content 10wt%) dispersion were changed to methyl methacrylate 5 Part, 0.2 part of divinylbenzene, 5 parts of positively charged CCA FCA-207P (80nm, solid content 20wt%) dispersion liquid, the same operation as in Example 1 was performed to obtain the suspension polymerization of the present invention with an average particle size of 8.2μm Toner. The evaluation results of the obtained toner characteristics are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com