Preparation method and application of hyperelastic porous CuAlNi high temperature shape memory alloy

A technology of memory alloy and superelasticity, which is applied in the field of preparation of superelastic porous CuAlNi high temperature shape memory alloy, can solve problems such as limiting the scope of application, and achieve good mechanical properties, superelasticity, and good high temperature cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Prepare Cu by arc melting 81.5 Al 14。5 Ni 4 (wt.%) alloy ingot;

[0046] (2) NaAlO with a purity of 99% and a particle size of 350~510μm 2 The powder is pressed into a green body, the pressing force is 10MPa, the temperature is 30°C, and the time is 10 minutes; the sintering is carried out in an air atmosphere, the sintering temperature is 1400°C, and the sintering time is 12 hours to obtain NaAlO 2 Block

[0047] (3) Put NaAlO 2 Put the block into the bottom of the tube furnace that can move up and down, and then place it in NaAlO 2 Put Cu on the block 81.5 Al 14.5 Ni 4 Alloy ingot, in 5×10 -3 Under Pa vacuum, keep at 1200℃ for 0.5h, then fill 1.2×10 5 Pa with argon gas and keep it for 2h, then move the tube furnace down out of the heating zone at a speed of 5mm / min, and get Cu after cooling 81.5 Al 14.5 Ni 4 And NaAlO 2 Composite materials;

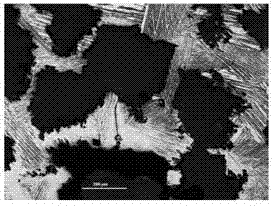

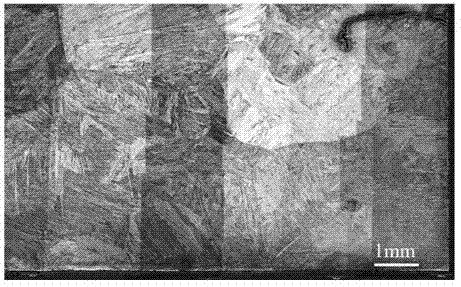

[0048] Cut this composite material and found that the CuAlNi alloy has been completely penetrated by NaAlO 2 In the interstices bet...

Embodiment 2

[0055] (1) Prepare Cu by arc melting 83 Al 13 Ni 4 (wt.%) alloy ingot;

[0056] (2) NaAlO with a purity of 99% and a particle size of 300~450μm 2 The powder is pressed into a green body, the pressing force is 50MPa, the temperature is 50°C, and the time is 5 minutes; the sintering is carried out in the air atmosphere, the sintering temperature is 1500°C, and the sintering time is 15 hours to obtain NaAlO 2 Block

[0057] (3) Put NaAlO 2 Put the block into the bottom of the tube furnace that can move up and down, and then place it in NaAlO 2 Put CuAlNi alloy ingot on the block, in 2×10 -3 Under Pa vacuum, keep it at 1250℃ for 5h, then charge 2×10 5 Pa with argon gas and keep it for 5h, then move the tube furnace down out of the heating zone at a speed of 1mm / min, and get CuAlNi and NaAlO after cooling 2 Composite materials;

[0058] Cut this composite material and found that the CuAlNi alloy has been completely penetrated by NaAlO 2 In the interstices between particles (such as Figure...

Embodiment 3

[0064] (1) Prepare Cu by arc melting 81.5 Al 14 Ni 4.5 (wt.%) alloy ingot;

[0065] (2) Combine NaAlO with 99% purity and 50μm particle size 2 The powder is pressed into a green body with a pressing force of 600MPa, a temperature of 100°C, and a time of 1 hour; sintering is carried out in an air atmosphere at a sintering temperature of 1500°C and a sintering time of 24 hours to obtain NaAlO 2 Block

[0066] (3) Put NaAlO 2 Put the block into the bottom of the tube furnace that can move up and down, and then place it in NaAlO 2 Put CuAlNi alloy ingot on the block, in 1×10 -3 Under Pa vacuum, keep at 1200℃ for 2h, and then charge 2×10 5 Pa with argon gas and keep it for 5h, then move the tube furnace downwards out of the heating zone at a speed of 5mm / min, and get CuAlNi and NaAlO after cooling 2 Composite materials;

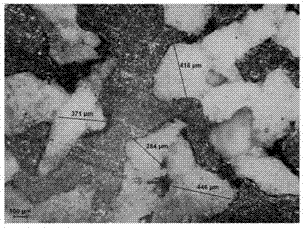

[0067] Cut this composite material and found that CuAlNi alloy basically did not infiltrate NaAlO 2 In the space between the particles, NaAlO 2 The boundary between the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com