Hydroxyapatite (HA)/ poly-amino acid compound particle and preparation method thereof

A technology of hydroxyapatite and composite particles, which is applied in the field of hydroxyapatite/polyamino acid composite particles and its preparation to achieve good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

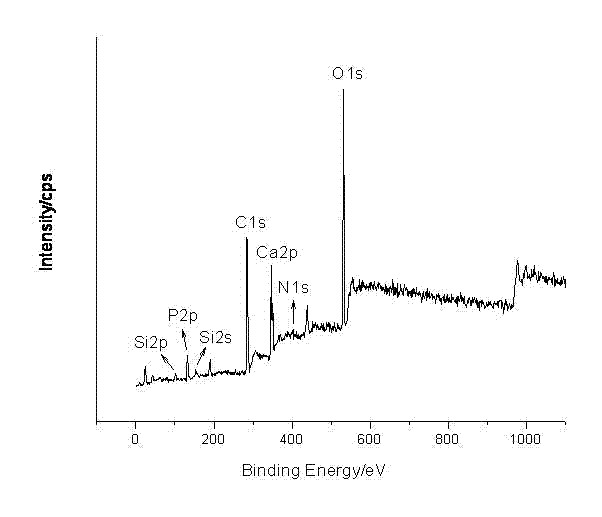

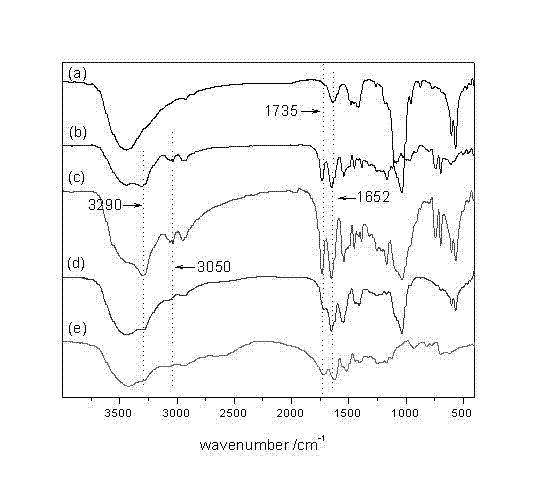

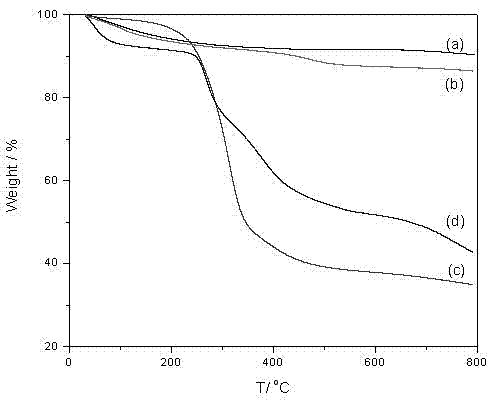

[0030] 1. Amination modification of hydroxyapatite: dissolve 1.105g 3-aminopropyltriethoxysilane (APS) in 450mL / 50mL ethanol / water mixed solvent, stir for half an hour; add 5.0g HA , then stirred at room temperature for 3~6 h; adjusted the pH to 9~10 with ammonia water, and then reacted for 3 h; filtered, and dried in vacuum at 50°C for three days to obtain surface aminated HA (HA-NH 2 ) particles, placed in a 50°C vacuum oven for later use.

[0031] 2. Preparation of hydroxyapatite-grafted polybenzyl glutamate (HA / PBLG) composite particles: add HA-NH to a dry 100mL eggplant-shaped bottle 2 Particles 1.200g, BLG-NCA 0.218g, freshly distilled dioxane 40mL; evacuate and circulate nitrogen for 3~5 times, keep the reaction bottle under nitrogen atmosphere, ultrasonically disperse for 0.5~1h; stir and react at 15~25℃ for 2~ 3d, the reaction solution turned into viscous liquid. The reaction solution was slowly poured into absolute ethanol for precipitation, and a white substance w...

Embodiment 2

[0034] Embodiment 2: This embodiment is basically the same as Embodiment 1, except that in step 1, the silane coupling agent used is N-(2-aminoethyl)-3-aminopropyltriethoxysilane ; In step 3, the quality of adding monomer BLG-NCA is 0.420g; in step 4, adding Me 3 The volume of SiI is 0.12 mL. The dosage and operating conditions of other reagents remained unchanged. The grafting rate of HA / PBLG composite particles was 16.28%, and the yield of HA / PLGA composite particles was about 75%.

Embodiment 3

[0035] Embodiment 3: This embodiment is basically the same as Embodiment 1, the difference is: in step 3, the mass of monomer BLG-NCA added is 0.844g; in step 4, the deprotecting agent used is trimethyl Chlorosilanes (0.18 mL). The dosage and operating conditions of other reagents remained unchanged. The grafting ratios of HA / PBLG and HA / PLGA composite particles were 28.23% and 20.58%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com