High heat resistance and low warping nylon 66 composite and preparation method thereof

A composite material and nylon technology, which is applied in the field of high heat resistance and low warpage nylon 66 composite material and its preparation, can solve the problem of poor long-term heat resistance effect of antioxidant system, warping deformation of parts, and reduce long-term heat resistance of nylon 66 composite material. performance and other issues, to achieve the effects of excellent long-term thermal oxygen aging performance, good interface bonding performance, and excellent dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

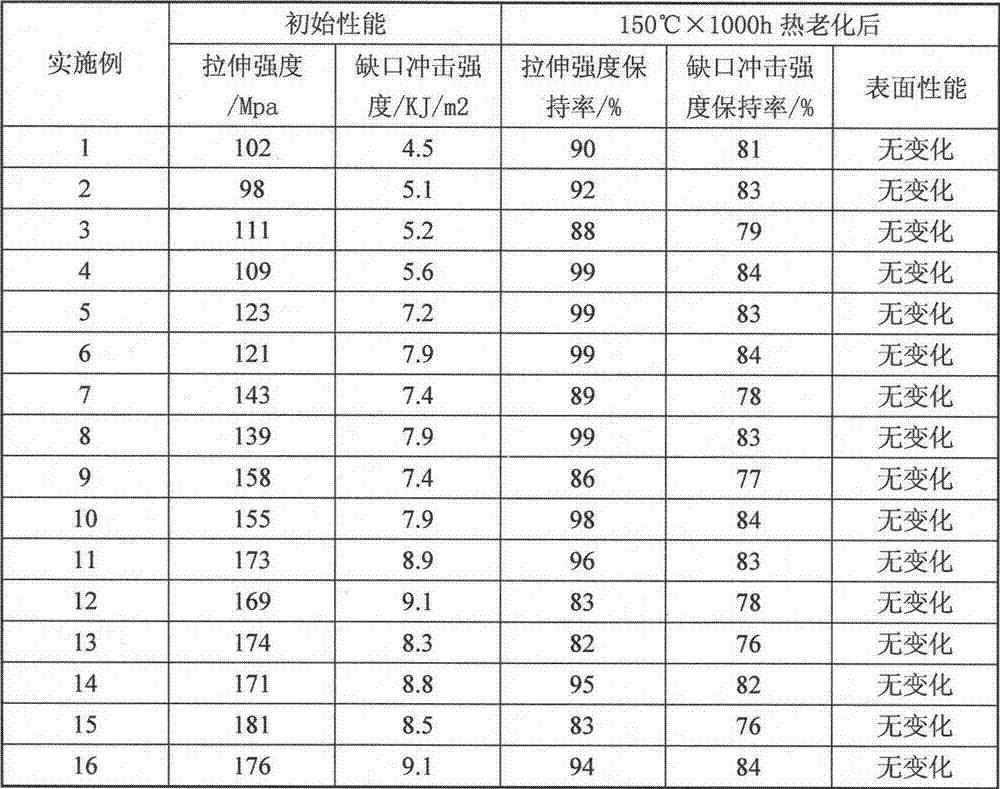

Examples

Embodiment 1

[0035] (1) Add 10 parts by weight of wollastonite with a particle size of 10 μm into a high-speed mixer preheated to 40°C, add 0.1 parts by weight of coupling agent KH550, and mix with a high-speed mixer to obtain surface-activated silica fume Stone, add 1# measuring scale;

[0036] (2) 79.6 parts by weight of pre-dried nylon 66 (relative viscosity 3.2), 0.1 part by weight of copper salt composite heat stabilizer (H3336, purchased from Bruggemann), 0.1 part by weight of talcum powder with a particle size of 1 μm Mix with 0.1 parts by weight of silicone masterbatch (MB50-002, purchased from Dow Corning Company) through a high-speed mixer to obtain pre-mixed raw materials, and add 2# weighing scale;

[0037] (3) The material measured by the 1# and 2# weighing scales is fed through the main feeder of the twin-screw extruder, and 10 parts by weight of alkali-free chopped glass fiber (10 μm in diameter of the monofilament, ECS301CL, purchased from Chongqing CPIC Company ) is measu...

Embodiment 2

[0039] (1) Add 10 parts by weight of kaolin with a particle size of 10 μm into a high-speed mixer preheated to 40°C, add 0.1 parts by weight of coupling agent KH550, 0.1 parts by weight of stearic acid, and 0.1 parts by weight of maleic anhydride, and use Mix with a high-speed mixer to obtain surface-activated kaolin, add 1# weighing scale;

[0040] (2) 78.6 parts by weight of pre-dried nylon 66 (relative viscosity 2.7), 0.1 part by weight of copper salt composite heat stabilizer (H3336, purchased from Bruggemann), 0.1 part by weight of antioxidant 1011, 0.3 Parts by weight of particle size are talc powder of 1 μm, 0.3 parts by weight of montanic acid ester, and 0.3 parts by weight of polyol ester (PETS, purchased from Lonza Corporation of the United States) are added in a high-speed mixer and mixed uniformly to obtain pre-mixed raw materials. Add 2# measuring scale;

[0041](3) The material measured by the 1# and 2# weighing scales is fed through the main feeder of the twin-...

Embodiment 3

[0043] (1) Add 20 parts by weight of wollastonite with a particle size of 10 μm into a high-speed mixer preheated to 50°C, add 0.2 parts by weight of coupling agent KH550, 0.2 parts by weight of stearic acid, and 0.2 parts by weight of maleic anhydride , mix with a high-speed mixer to obtain surface-activated wollastonite, and add 1# weighing scale;

[0044] (2) 67.6 parts by weight of pre-dried nylon 66 (relative viscosity 2.7), 0.3 parts by weight of antioxidant 1098, 0.3 parts by weight of antioxidant 168, 0.3 parts by weight of montmorillonite with a particle size of 1 μm, 0.3 parts by weight of The montanic acid ester of 0.3 weight part, the polyol ester (PETS, purchased from U.S. Lonza Company) of 0.3 weight part and the silicone masterbatch (MB50-002, purchased from Dow Corning Company) of 0.3 weight part) add in the high-speed mixer and mix homogeneously After that, add 2# measuring scale;

[0045] (3) The material measured by the 1# and 2# weighing scales is fed thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com