Control method of mix ratio of low-strength backfill materials

A control method and low-strength technology, applied in the field of municipal engineering and highway engineering concrete engineering, can solve the problems of dust pollution, biological hazards, and lack of a set of CLSM mixtures, etc., to achieve good fluidity, simple construction, and good volume stability The effect of resistance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

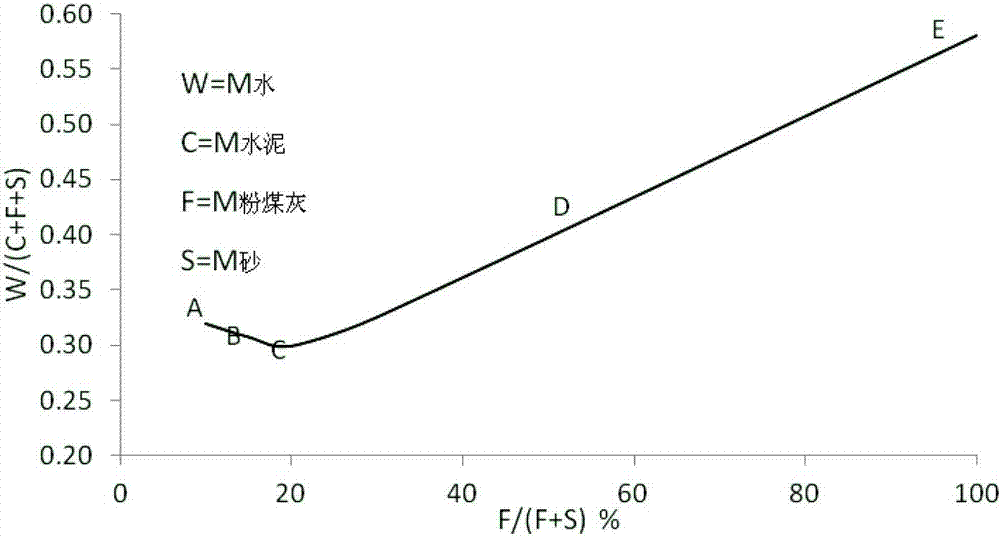

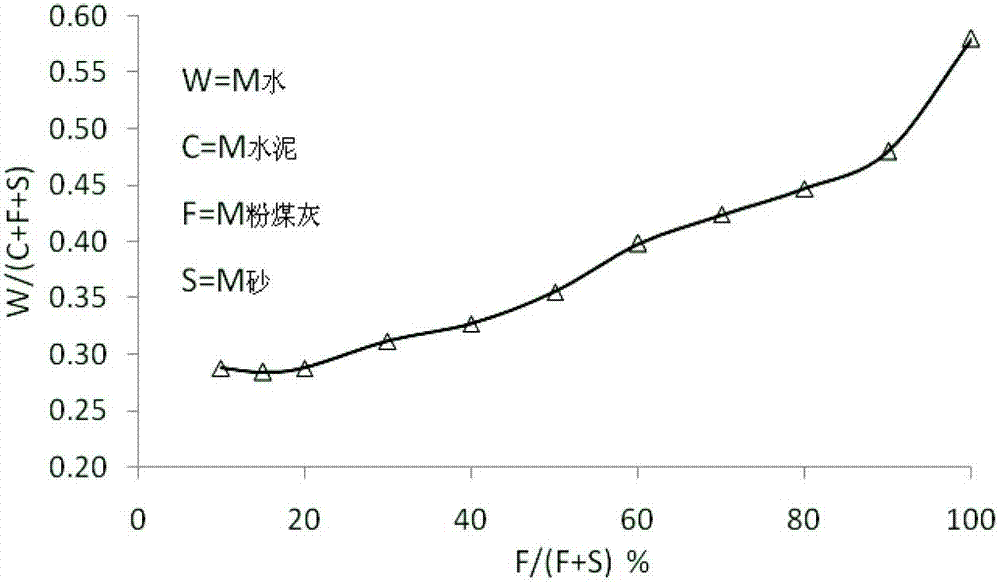

[0055] A building medium sand (fineness modulus of 2.3-3.0, average particle size of 0.35mm) is selected as the fine aggregate, and the fly ash is grade III fly ash (fineness not greater than 45%, water demand Ratio is not more than 115%, loss on ignition is not more than 15%, water content is not specified, sulfur trioxide content is not more than 3%), draw the fluidity curve as figure 2 shown.

[0056] From the fluidity curve, the minimum water consumption point is obtained around F / (F+S)=20%. Take the corresponding K1=20%, K2=0.288 for mix ratio design. The project is a general backfill project, take f 目标 =0.7Mpa.

[0057] The cement content was 2%, 4%, 6%, 8%, and 10%, respectively, and 5 sets of specimens were prepared, each with 3 parallel specimens (diameter 100mm, height 200mm). Put them in a standard curing room for curing, take them out of the curing room after 28 days and test the unconfined compressive strength of the specimens, the average values of each gr...

Embodiment 2

[0069] Referring to Example 1, the minimum water consumption point is obtained around F / (F+S)=20%. Take the corresponding K 1 =20%, K 2 =0.288 for mix ratio design. If the above materials are used in non-excavable backfill projects, the design strength value is taken as f 目标 =1.1Mpa.

[0070] From the results in Table 1, we can see that f 目标 =1.1Mpa falls between intensity values 0.648 and 1.352, C 左 =4%, C 右 =6%, the corresponding compressive strength is f 左 =0.648Mpa, f 右 =1.352Mpa. Assuming that there is a linear relationship between strength and cement content, using linear interpolation, the 28-day strength is calculated as f 目标 The corresponding estimated cement content is:

[0071]

[0072] The obtained mix ratio is calculated by weight as cement content 5.3%, fly ash content 20%×(1-5.3%)=18.9%, sand content 1-5.3%-18.9%=75.8%, water content for K 2 =28.8%.

[0073] The mix ratio finally determined to be used is cement: fly ash: sand aggregate: water=5...

Embodiment 3

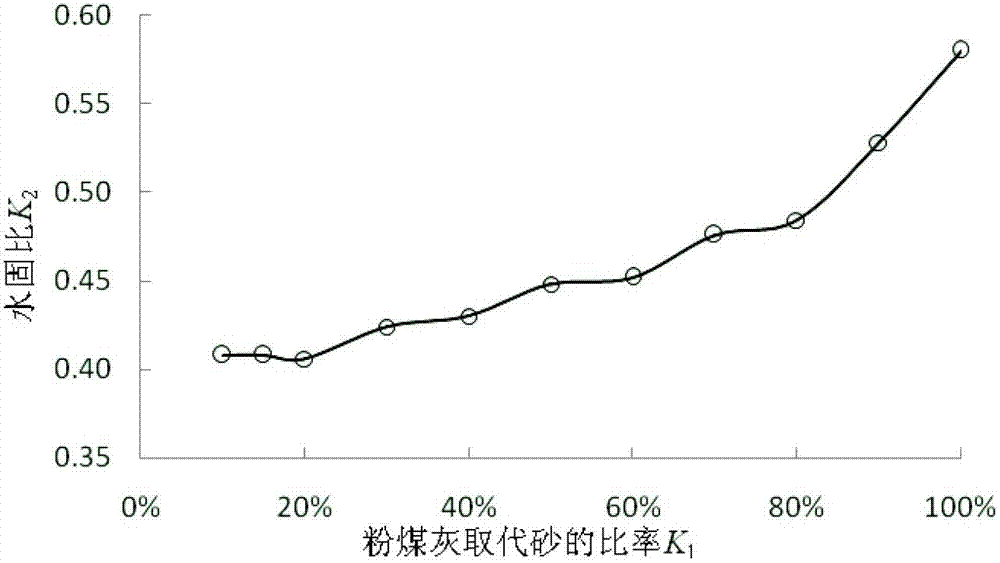

[0080] An alluvial island in the Yangtze River Estuary needs to bury optical fiber pipelines in order to improve the quality of telecommunications services on the island. Since the island is rich in fine sand from the Yangtze Estuary and relatively lacking in other aggregates, the fine sand from the Yangtze River Estuary was selected as the raw material aggregate component with an average particle size of 0.15 mm. The cement is the most common 325-grade composite Portland cement in the local market, and the fly ash is the low-calcium third-grade ash of the power plant. The project is an ordinary road backfill project without special requirements. Therefore, the fluidity requirement of the road fluid backfill material is taken as the slump expansion degree of 28cm, and the design strength is taken as the 28-day unconfined compressive strength f 目标 =0.7MPa.

[0081] The specific process of mix ratio design is as follows:

[0082] Draw the flowability curve of the selected raw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com