Manufacturing method of high-purity spherical pearlite intermediate

A technology of spherical pearlite and production method, which is applied in the field of metal heat treatment, can solve the problems that the decarburization layer is difficult to meet the actual use requirements, the increase of production cost investment, and the low annealing efficiency, etc., so as to enhance the movement speed and activity energy of electrons, and improve the heat treatment efficiency. Efficiency and short spheroidization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: A kind of preparation method of high-purity spherical pearlite intermediate comprises two parts of material pretreatment and electromagnetic spheroidization heat treatment, and its specific operation steps are as follows:

[0024] (1) Material pretreatment:

[0025] A. Heat the workpiece with a carbon content of 0.8% to 1150°C and keep it warm for 60 minutes;

[0026] B. The heated workpiece is hot-extruded on the fungus punching machine, and the compression ratio is 5.2;

[0027] C. Air-mist cooling the compressed workpiece to below 100°C with a cooling rate of 50°C / min;

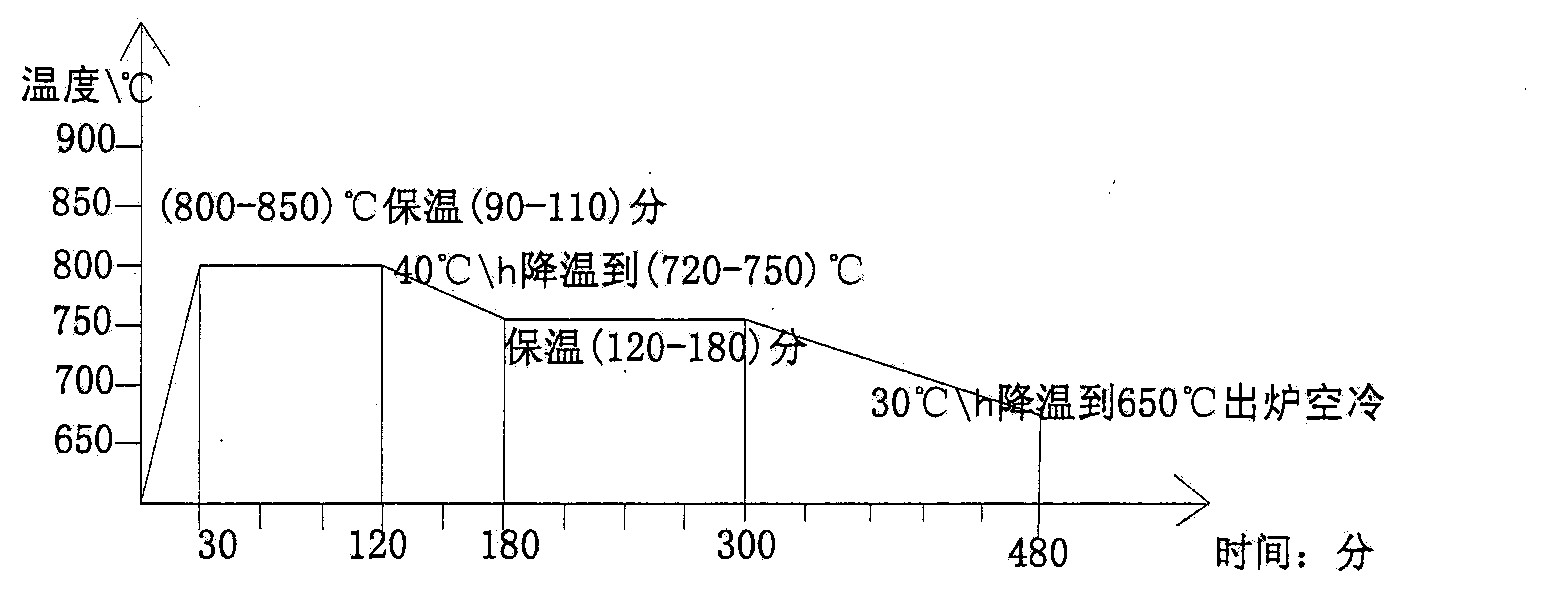

[0028] (2) Electromagnetic spheroidization heat treatment:

[0029] A. Connect both ends of the pretreated workpiece to an adjustable AC power supply of 750V;

[0030] B. Place the workpiece connected to the power supply in the induction magnetic field of the DC 24V electromagnetic coil, the ratio of the cross-sectional area of the electromagnetic coil to the cross-sectional area o...

Embodiment 2

[0032] Embodiment 2: A kind of preparation method of high-purity spherical pearlite intermediate comprises two parts of material pretreatment and electromagnetic spheroidization heat treatment, and its specific operation steps are as follows:

[0033] (1) Material pretreatment:

[0034] A. Heat the workpiece with a carbon content of 0.8% to 1180°C and keep it warm for 50 minutes;

[0035] B. The heated workpiece is hot-extruded on the fungus punching machine, and the compression ratio is 6.0;

[0036] C. Air-mist cooling the compressed workpiece to below 100°C, the cooling rate is 60°C / min;

[0037] (2) Electromagnetic spheroidization heat treatment:

[0038] A. Connect both ends of the pretreated workpiece to an adjustable AC power supply of 850V;

[0039] B. The workpiece connected to the power supply is placed in the induction magnetic field of the DC 42V electromagnetic coil, the current I=3A, the ratio of the cross-sectional area of the electromagnetic coil to the cr...

Embodiment 3

[0041] Embodiment 3: A kind of preparation method of high-purity spherical pearlite intermediate comprises two parts of material pretreatment and electromagnetic spheroidization heat treatment, and its specific operation steps are as follows:

[0042] (1) Material pretreatment:

[0043] A. Heat the workpiece with a carbon content of 1.0% to 1200°C and keep it warm for 60 minutes;

[0044] B. The heated workpiece is hot-extruded on the fungus-type punching machine, and the compression ratio is 6.5;

[0045] C. Air-mist cooling the compressed workpiece to below 100°C with a cooling rate of 55°C / min;

[0046] (2) Electromagnetic spheroidization heat treatment:

[0047] A. Connect both ends of the pretreated workpiece to an adjustable AC power supply of 1000V;

[0048] B. The workpiece connected to the power supply is placed in the induction magnetic field of the DC 50V electromagnetic coil, the current I=3A, the ratio of the cross-sectional area of the electromagnetic coil t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com