Method for preparing amino silicon oil modified acrylic resin leather finishing agent

A technology of acrylic resin and leather finishing agent, which is applied in the fields of leather surface treatment, small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather skin/fur chemical treatment, etc. It can solve limitations, poor stability, Difficult to store and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

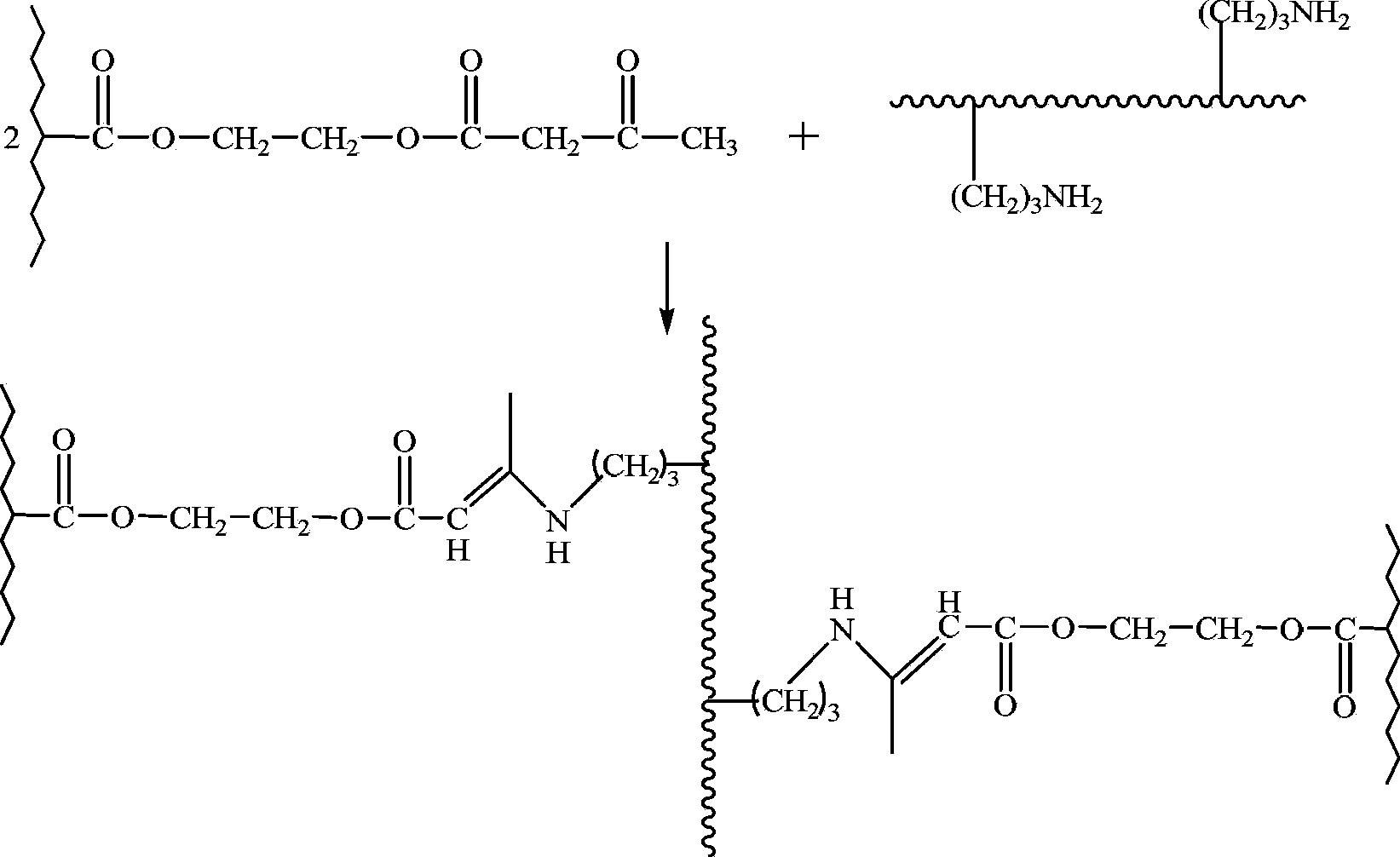

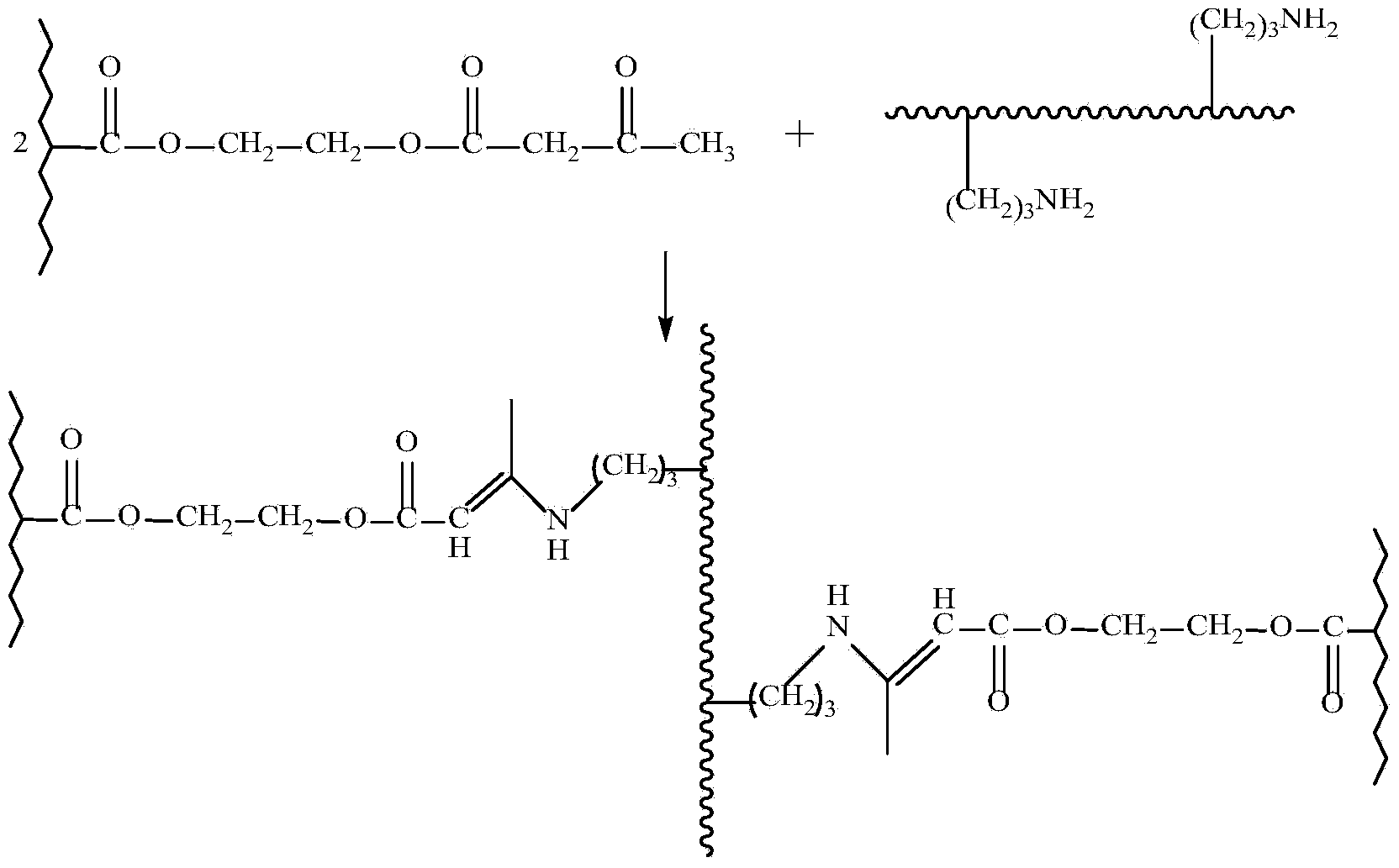

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of amino silicone oil modified acrylic resin leather finishing agent, comprising the following steps:

[0027] 1) Preparation of monomer pre-emulsion

[0028] Mix 30g of butyl acrylate, 8g of methyl acrylate, 1g of methacrylic acid, and 1g of acetoacetoxyethyl methacrylate (AAEM) evenly, and add them dropwise within 0.5h to 40g of deionized water, 2g of dodecyl In the emulsifier solution composed of sodium sulfate and 1g OS15, OS15 is fatty alcohol polyoxyethylene ether, n=15, the temperature in the reactor is controlled at 40°C, after the addition is completed, stir at 40°C for 1 hour to obtain a mixed single body pre-emulsion;

[0029] 2) Preparation of acrylic resin emulsion

[0030] Based on the total mass fraction of the mixed monomer pre-emulsion, take 10% of the pre-emulsion, 0.05g of ammonium persulfate initiator and 10g of deionized water and add them to another reactor to mix evenly, raise the temperature to 75°C, and wait After the emu...

Embodiment 2

[0037] A preparation method of an amino silicone oil modified acrylic resin leather finishing agent, specifically comprising the following steps:

[0038] 1) Preparation of monomer pre-emulsion

[0039] Mix 25g of butyl acrylate, 10g of methyl acrylate, 1.5g of methacrylic acid, and 3g of acetoacetoxyethyl methacrylate (AAEM) evenly, and add them dropwise within 0.5h to 40g of deionized water, 2g of dodecane In the emulsifier solution composed of sodium hydroxysulfate and 1g OS15, OS15 is fatty alcohol polyoxyethylene ether, n=15, the temperature in the reactor is controlled at 45°C, after the addition is completed, stir for 1h at 45°C to obtain a mixed monomer pre-emulsion;

[0040] 2) Preparation of acrylic resin emulsion

[0041] Based on the total mass fraction of the mixed monomer pre-emulsion, take 10% of the pre-emulsion, 0.075g of ammonium persulfate initiator and 10g of deionized water and add them to another reactor to mix evenly, raise the temperature to 82.5°C, a...

Embodiment 3

[0048] A preparation method of an amino silicone oil modified acrylic resin leather finishing agent, specifically comprising the following steps:

[0049] 1) Preparation of monomer pre-emulsion

[0050] Mix 20g of butyl acrylate, 15g of methyl acrylate, 2g of methacrylic acid, and 2g of acetoacetoxyethyl methacrylate (AAEM) evenly, and add them dropwise within 0.5h to 40g of deionized water, 2g of dodecyl In the emulsifier solution composed of sodium sulfate and 1g OS15, OS15 is fatty alcohol polyoxyethylene ether, n=15, the temperature in the reactor is controlled at 50°C, after the addition is completed, stir at 50°C for 1 hour to obtain a mixed single body pre-emulsion;

[0051] 2) Preparation of acrylic resin emulsion

[0052] Based on the total mass fraction of the mixed monomer pre-emulsion, take 10% of the pre-emulsion, 0.1g of ammonium persulfate initiator and 10g of deionized water and add them to another reactor to mix evenly, heat up to 90°C, and wait After the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com