Preparation method for photoinitiators containing phosphorus

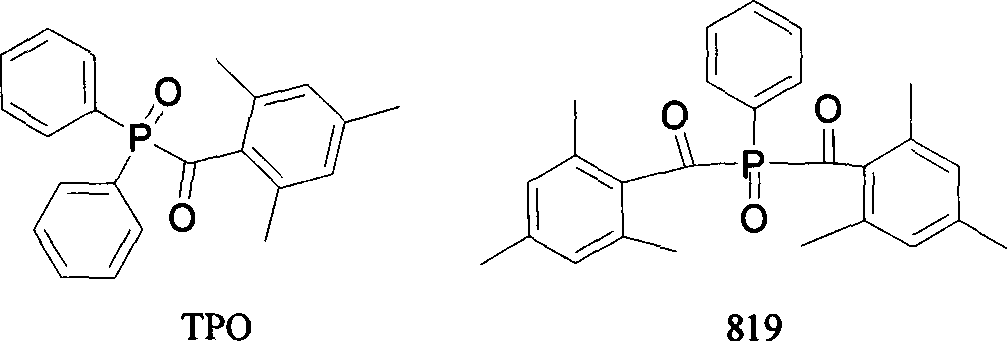

A photoinitiator and solvent technology, applied in the field of preparation of phosphorous photoinitiators, can solve the problems of harsh reaction conditions, high equipment requirements, and many three wastes, and achieve the effects of less three wastes, high yield and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

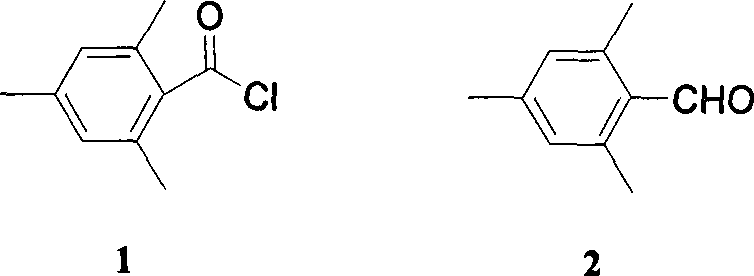

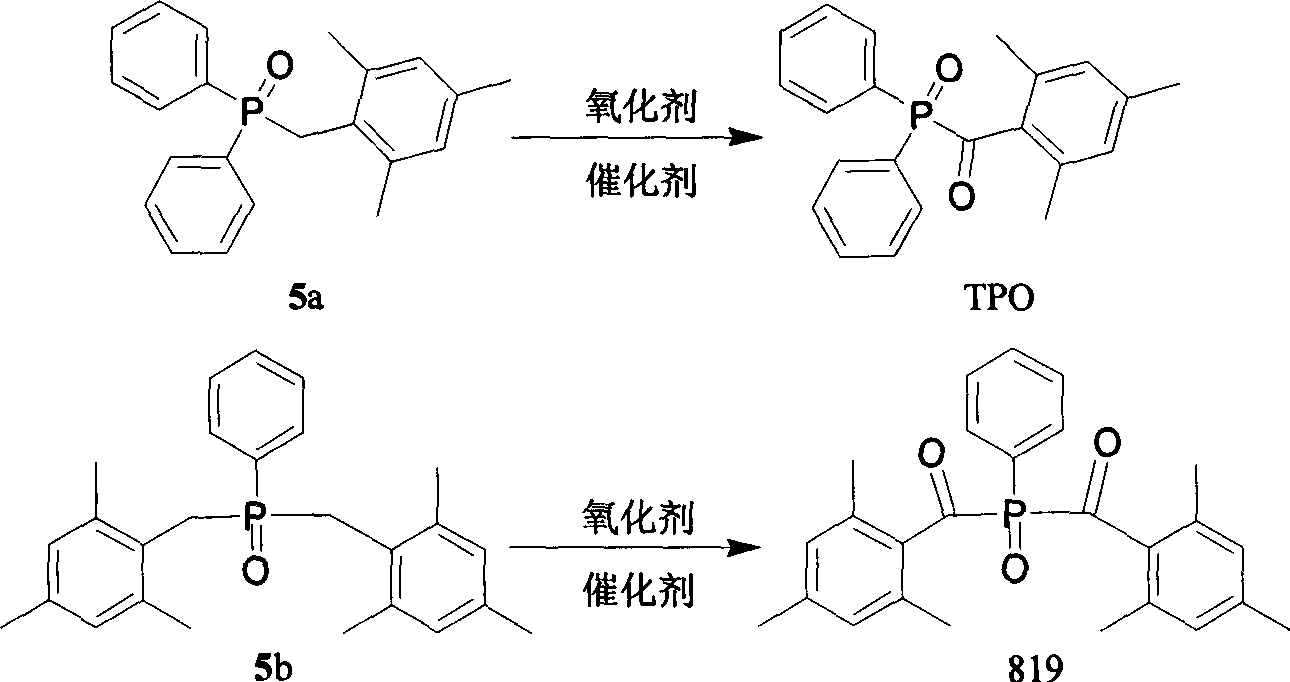

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: the preparation of 2,4,6-trimethylbenzyl chloride

[0029] Get 400g mesitylene, 1.1L hydrochloric acid (36%), 0.5g phase transfer catalyst octadecyltrimethylammonium bromide (CTAB) after mixing evenly, stir at room temperature for 2h, add 110g paraformaldehyde under stirring, heat up 75 ℃, reacted for 4 hours, and monitored the reaction by GC. After the reaction was completed, cool down to room temperature, add a small amount of isopropanol to break the emulsion, and extract with dichloromethane. The organic phase obtained was first washed with 2mol / L sodium hydroxide solution, and then washed with water. It was dried with anhydrous sodium sulfate and fractionated to collect the fraction with a boiling point of 130-140°C, that is, 2,4,6-trimethylbenzyl chloride, with a yield of 85% and a melting point of 38°C.

Embodiment 2

[0030] Embodiment 2: the preparation of 2,4,6-trimethylbenzyl bromide

[0031] Take 400g mesitylene, 1.5L hydrogen bromide (40%), 0.7g phase transfer catalyst octadecyltrimethylammonium bromide (CTAB) and mix evenly, stir at room temperature for 2h, add 110g paraformaldehyde under stirring, Raise the temperature to 40-45°C, react for 3.5 hours, and monitor the reaction by GC. After the reaction, cool down to room temperature, add a small amount of isopropanol to break the emulsification, extract with 600ml of dichloromethane, stir evenly, put the separatory funnel to stand for stratification, and separate The organic layer was taken out, the aqueous layer was extracted twice with 300ml dichloroethane, the combined organic layers were washed with 5% N a HCO 3 Wash once with 400ml of aqueous solution, separate the water layer, wash twice with 400ml of water, dry over magnesium sulfate, remove the solvent, distill under reduced pressure, collect: 118°C / 2mmHg fraction 622g, yield...

Embodiment 3

[0032] Embodiment 3: the preparation of sodium phenyl phosphide

[0033]Under the protection of nitrogen, suspend sodium block (10.3g, 0.448mol) in 400g of anhydrous toluene at room temperature, stir and heat to reflux, when the temperature rises to 98°C, start stirring vigorously for 0.5-1h to form sodium sand, and reflux Dichlorophenylphosphine (20.1 g, 0.112 mol) was dissolved in 170 g of toluene under the conditions, and was added dropwise to sodium sand. The drop was completed in 1 hour, and the reaction was refluxed for 24 hours to obtain a bright yellow precipitate. Since sodium phenyl phosphide is unstable, the next step reaction was not carried out without separation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com