Emulsifying agent for industrial explosive and preparation method of emulsifying agent

A technology of industrial explosives and emulsifiers, applied in non-explosive/non-thermal agent components, explosives, offensive equipment, etc., can solve the problems of poor storage stability of emulsion explosives and high requirements for emulsification conditions, achieve high performance and storage stability, and improve Intrinsic safety, the effect of reducing the amount of emulsifier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

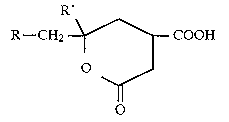

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Add 150g of polyisobutylene (Mn=1000) into the reaction kettle, heat to 130°C, add 16g of maleic anhydride, blow nitrogen to the pressure to 0.1mpa, heat up to 200°C, react for 4h, then blow off unreacted horses with nitrogen The prepared polyisobutylene maleic anhydride (olefin anhydride) will be used in the next reaction. Take 33g of olefinic anhydride and 0.5g of water, stir evenly in the reactor, increase the temperature to 70℃, add 0.8g of concentrated sulfuric acid (mass concentration is 98%), increase the temperature to 110℃ and react for 1h, add 1.4g of sodium carbonate and continue the reaction for 1h. 4g of triethanolamine was added to 130°C, and after the addition, the temperature was raised to 180°C and nitrogen was blown to 0.1mpa, and reacted for 4h to obtain the target product emulsifier.

Embodiment 2

[0026] Example 2: Add 195g polyisobutylene (Mn=1300) into the reaction kettle, heat to 170°C, add 21g fumaric anhydride, blow nitrogen to the pressure to 0.2mpa, heat up to 220°C, react for 7h, and then blow off the unreacted rich Maleic anhydride, the prepared polyisobutylene fumaric anhydride (olefin anhydride) will be used in the next reaction. Take 33g of olefinic anhydride and 0.3g of water, stir well in the reactor, increase the temperature to 50℃, add 2g of concentrated sulfuric acid, increase the temperature to 130℃ and react for 1h, add 2.5g of sodium carbonate and continue the reaction for 1h, increase to 160℃, add 6g of sorbitol After the addition, the temperature is raised to 150°C and nitrogen is blown to 0.2mpa, and the reaction is 6h to obtain the target product emulsifier.

Embodiment 3

[0027] Example 3: Put 150g polyisobutylene (Mn=1000) into the reaction kettle, heat to 150°C, add 19g maleic anhydride, bubbling nitrogen to a pressure of 0.15mpa, heating up to 230°C, reacting for 5h, then bubbling nitrogen to purge unreacted horses The prepared polyisobutylene maleic anhydride (olefin anhydride) will be used in the next reaction. Take 33g of olefinic anhydride and 0.8g of water, stir evenly in the reactor, increase the temperature to 70℃, add 1g of hydrochloric acid (mass concentration 37%), increase the temperature to 130℃ and react for 1h, add 1.5g of sodium carbonate and continue the reaction for 1h, and increase the temperature to 150℃ Add 10g of tetraethylenepentamine, after the addition, the temperature is raised to 190°C and nitrogen is blown to 0.2mpa, and reacted for 6h to obtain the target product emulsifier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com