Method for synthesizing spherical nano-zirconia by using detonation method in grain diameter controllable manner

A nano-zirconia and spherical technology, which is applied in the field of detonation synthesis of nano-materials, can solve the problems of consumption, multiple lye, and multiple by-products, and achieve the effects of high purity, low environmental pollution, and small product particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Get 100g raw material according to the formula of the present invention, wherein ozokerite 8g, sorbitan oleate 3.5g, sodium nitrite 0.5g, zirconium nitrate pentahydrate 72g, ammonium nitrate 15g, water 1g.

[0024] Mix zirconium nitrate pentahydrate, ammonium nitrate and water, heat to dissolve, and keep the temperature of the solution at 120°C; melt ozokerite and sorbitan oleate, mix well, and keep the solution temperature at 120°C; adjust the stirring blade The rotating speed is 3000r / min, and the above two solutions are mixed to form a water-in-oil paste.

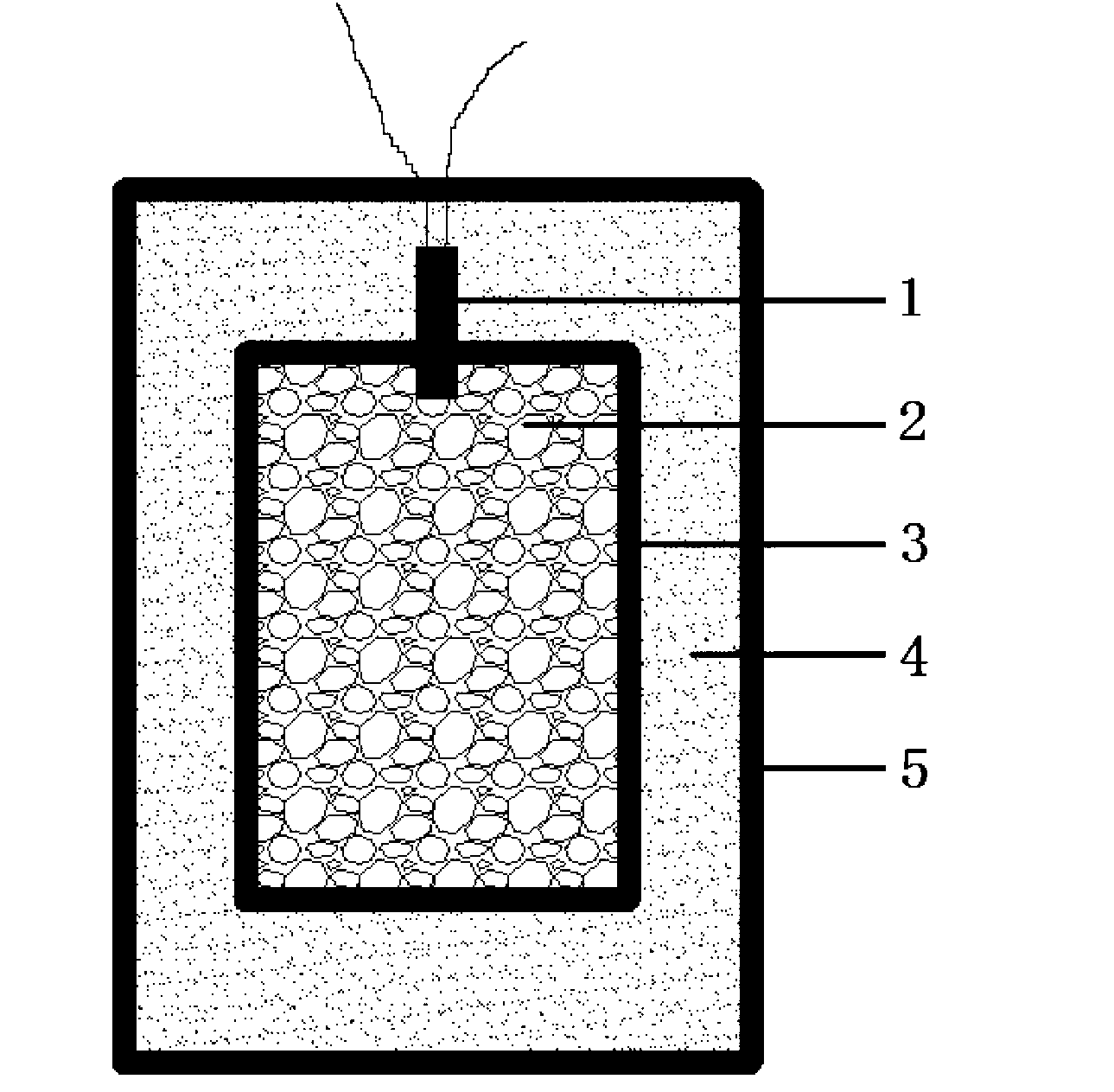

[0025] When the temperature of the paste is 90-100°C, add sodium nitrite to the above-mentioned water-in-oil type paste, and mix it well with the paste; fill the prepared paste on paper In rolls, the charge density is 1.15g / cm 3 ; according to the attached figure 1 Assemble No. 8 industrial electric detonator, explosible paste medicine roll and inert cooling medium, then put into the explosion jar to detonate. ...

Embodiment 2

[0029] Get 100g raw material according to the formula of the present invention, wherein paraffin 3g, polyisobutylene succinimide 5g, resin microsphere 1g, ammonium nitrate 20g, zirconium nitrate pentahydrate 66g, water 5g.

[0030] Mix ammonium nitrate, zirconium nitrate pentahydrate with water, heat to dissolve, and keep the temperature of the solution at 110°C; melt the paraffin and polyisobutylene succinimide, mix well, and keep the solution temperature at 120°C; adjust the rotation speed of the stirring paddle to 2000r / min, mix the above two solutions to form a water-in-oil paste.

[0031] When the temperature of the paste is 90-100°C, add resin microspheres to the above-mentioned water-in-oil type paste, and make it fully mixed with the paste; fill the prepared paste on paper In the roll, the charge density is controlled at 1.05g / cm 3 ; according to the attached figure 1 Assemble the No. 8 industrial electric detonator, explosive paste roll and inert cooling medium, an...

Embodiment 3

[0035] Take 100g of raw materials according to the formula of the present invention, including 3g of machine oil, 1.4g of paraffin, 1g of polyoxyethylene stearate, 1g of polyoxyethylene abietate, 0.6g of sensitizer (bicarbonate+organic coupling compound), 0.6g of nitric acid Ammonium 30g, zirconium nitrate pentahydrate 60g, water 3g.

[0036] Mix ammonium nitrate, zirconium nitrate pentahydrate with water, heat to dissolve, and keep the temperature of the solution at 120°C; melt engine oil, polyoxyethylene stearate, and polyoxyethylene abietic acid, mix well, and keep the temperature of the solution at 120°C °C; adjust the rotation speed of the stirring paddle to 1000r / min, and mix the above two solutions to form a water-in-oil type paste.

[0037] When the temperature of the paste is 90-100°C, add a sensitizer to the above-mentioned water-in-oil type paste, and mix it thoroughly with the paste; fill the prepared paste on paper In the roll, the charge density is controlled at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com