Built-in porous heater

A heater, built-in technology, applied in the direction of heating element material, heating element shape, etc., can solve the problems of large volume, can not meet the small electric thruster, heat resistance temperature is only 600 ℃, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention is described in detail below through specific embodiments and accompanying drawings.

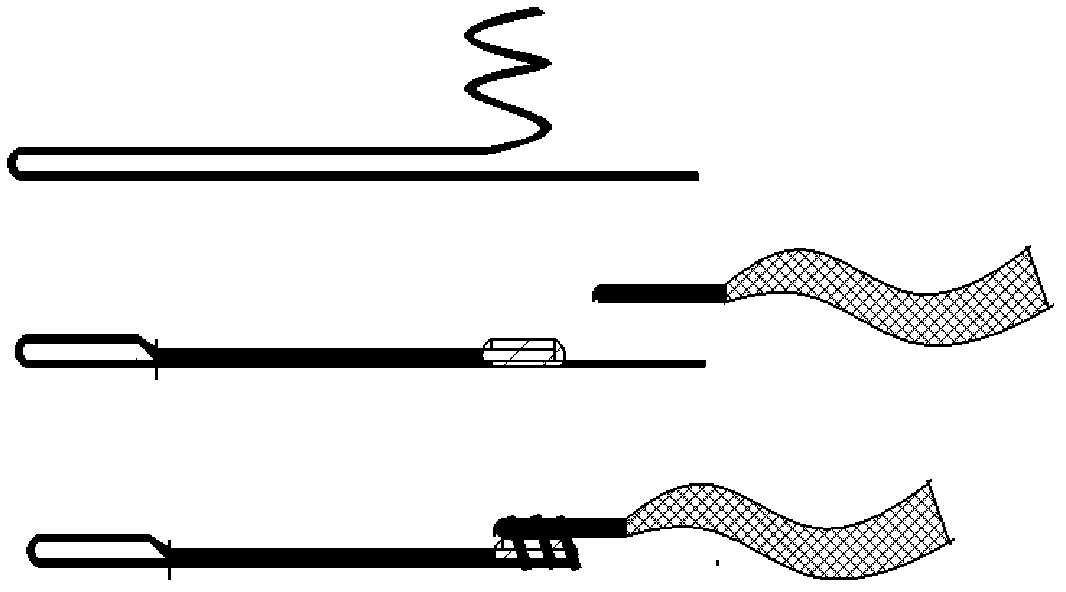

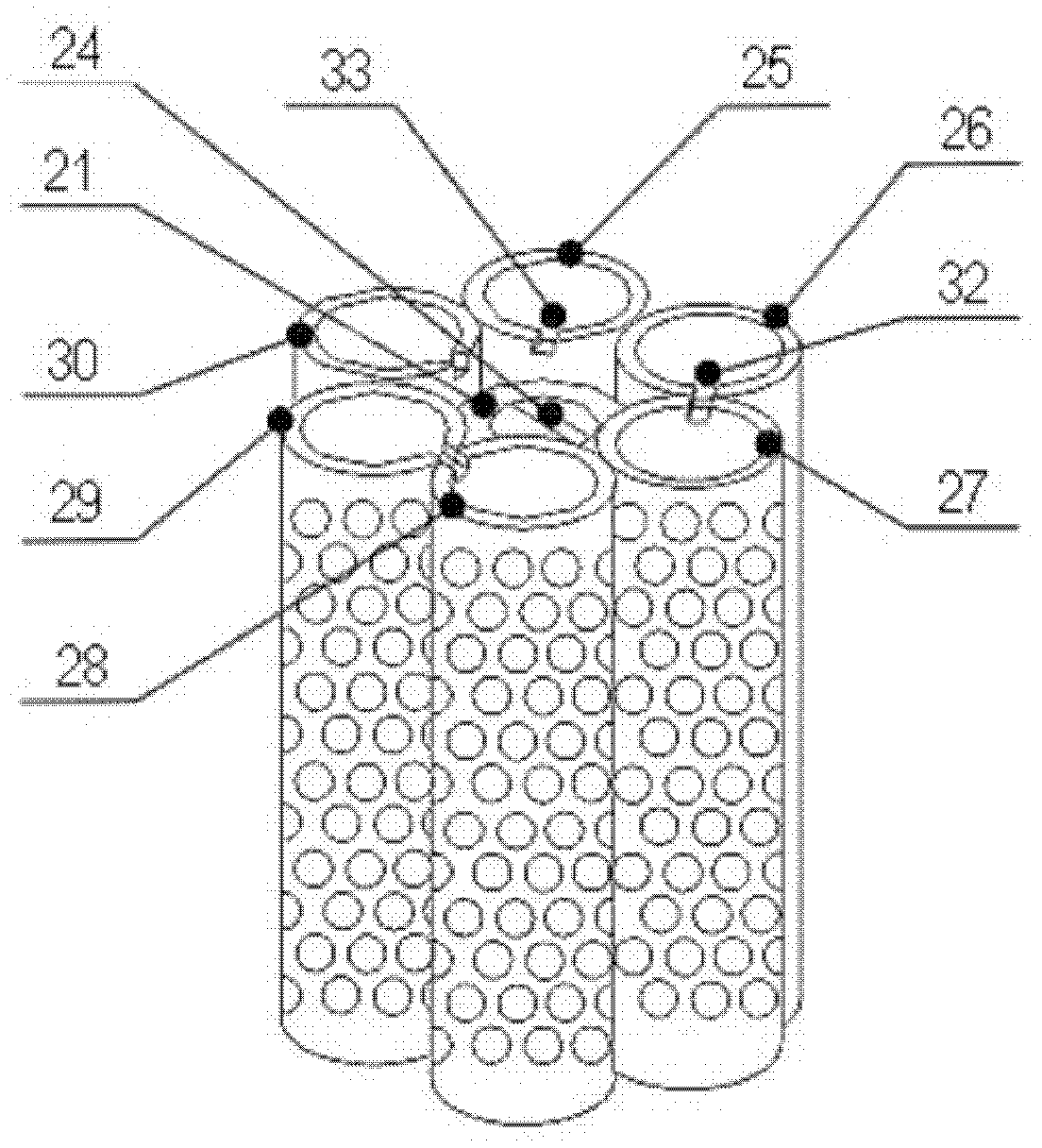

[0066] Take the heating element required by the electric heating hydrazine thruster as an example, and refer to Figure 1-6 .

[0067] Cut the nickel foam material into long strips of 1.5mm×1.2mm×1000mm, wind it into a spiral shape with a pitch of 0.5mm and a diameter of 1.0mm, and use solid phase infiltration technology to chrome it or chrome it and then infiltrate it Aluminum, a three-dimensional mesh porous nickel-chromium or nickel-chromium-aluminum heating element formed after vacuum heat treatment.

[0068] Use a laser processing machine to evenly and densely drill holes with a diameter of Φ1.0mm and a hole distance of 1.8mm on the tube wall of a boron nitride tube (diameter 5mm, wall thickness 0.5mm) with a length of 25mm to make a porous boron nitride tube; at the same time Use a micro-drill to make grooves on the pipe wall at both ends of the pipe, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com