Method for preparing high-efficiency membrane electrode of direct methanol fuel cell

A methanol fuel cell, high-efficiency membrane technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of difficulty in ensuring the consistency of membrane electrode performance, complex membrane electrode preparation process, and difficulty in establishing proton channels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

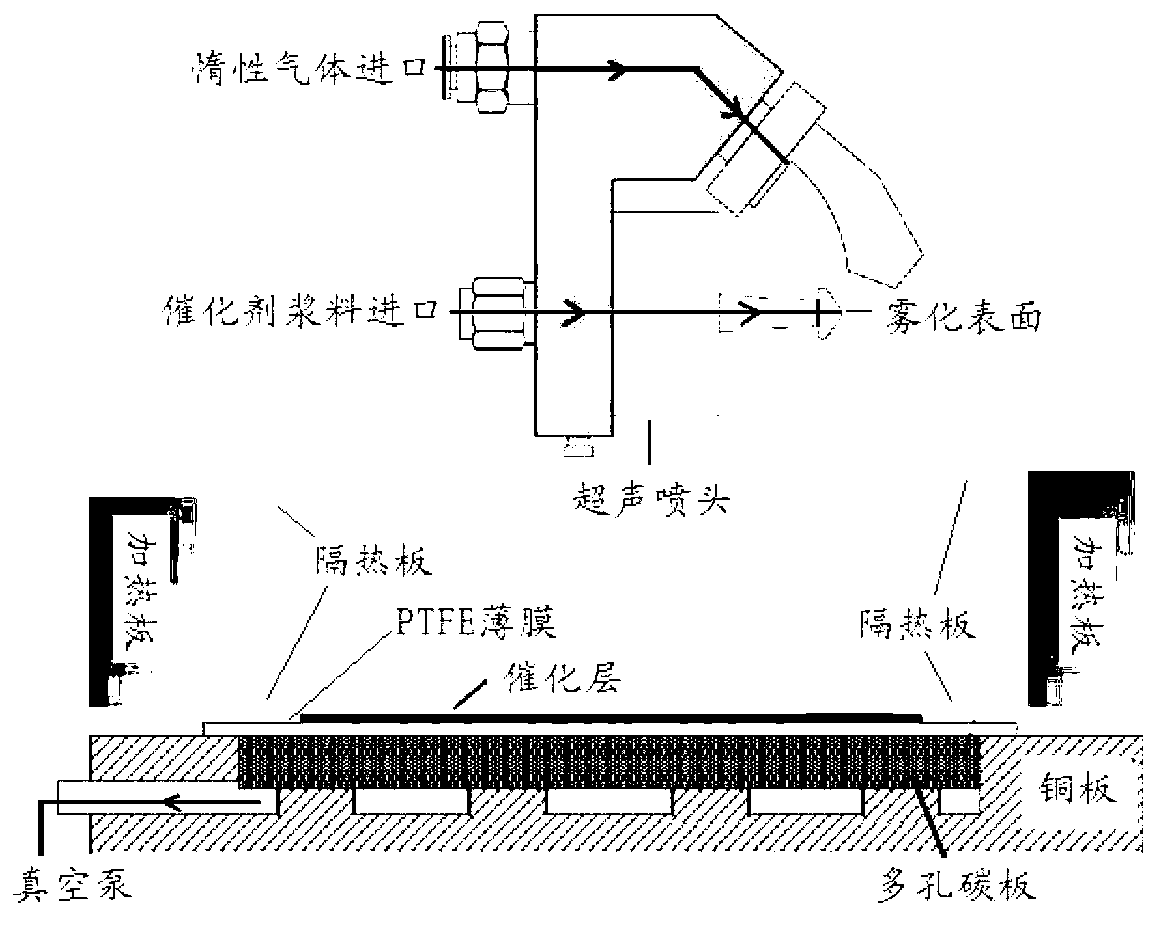

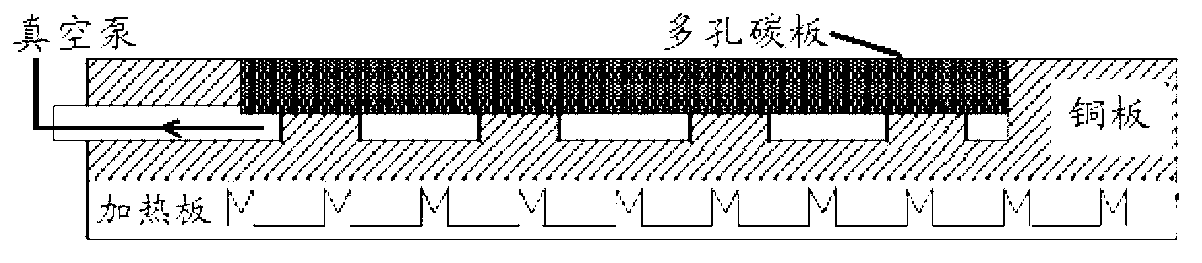

[0030]1. Spray system assembly. A copper heating plate is placed between the ultrasonic nozzle and the PTFE film, and the upper and lower parts of the heating plate are separated by a heat shield so as not to affect the normal operation of the ultrasonic nozzle. If the spraying area is rectangular, four heating plates are used to enclose it, and the heating plate is 1cm away from the edge of the spraying surface.

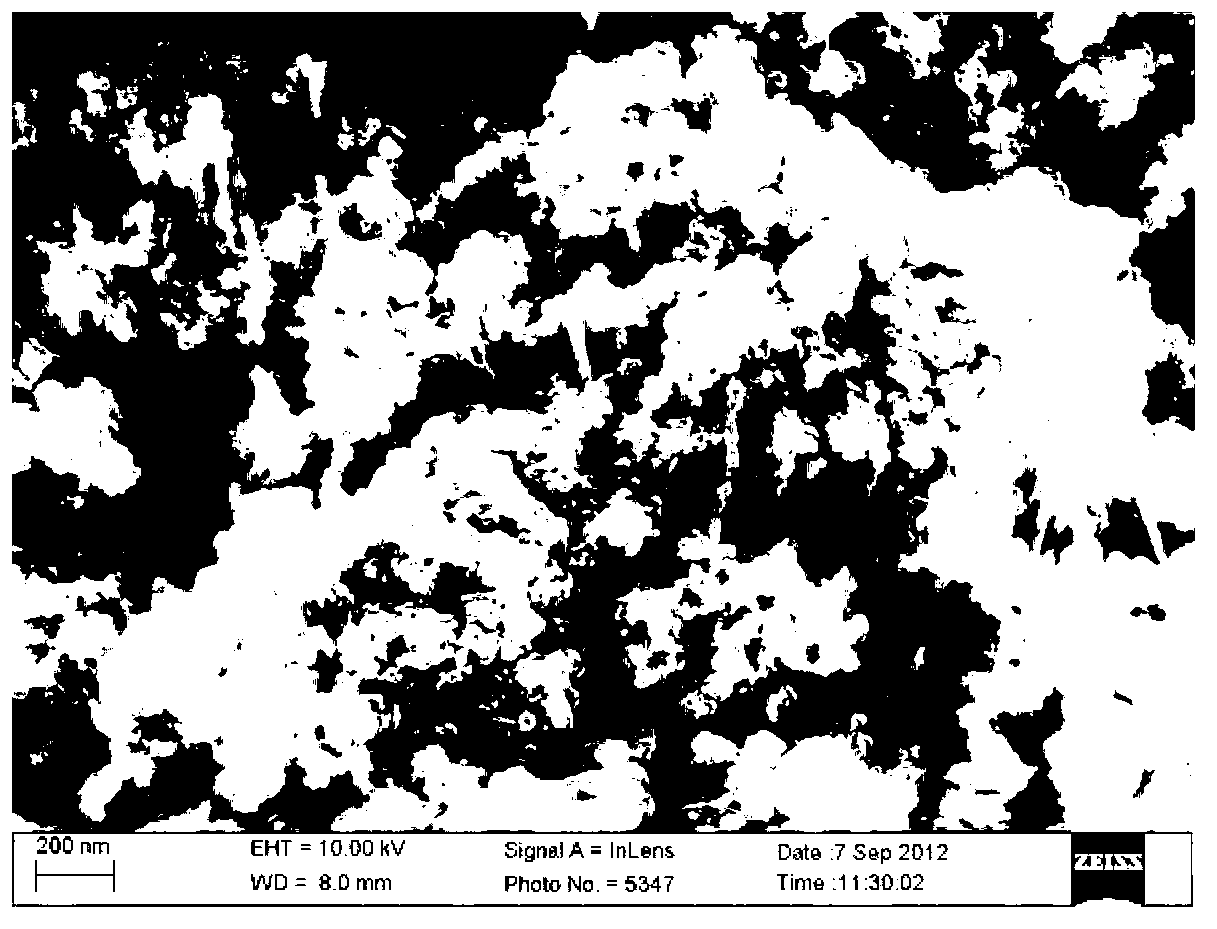

[0031] 2. Preparation of catalyst slurry and preparation of catalytic layer. Choose 4 mg / cm for cathode and anode respectively 2 Pt black and 4 mg / cm 2 The PtRu black catalysts are all used with a solid content loading of 0.44 mg / cm 2 The 5 wt % Nafion solution was used as the binder, both using 174.44 mg / cm 2 of isopropanol and 10.55 mg / cm 2 of water as a dispersant. The glove box was evacuated and filled with argon. The catalyst was weighed in the glove box, the slurry was prepared, and the catalyst slurry was prepared by ultrasonic dispersion using an ultr...

Embodiment 2

[0038] 1. Spray system assembly. A stainless steel heating plate is placed between the ultrasonic nozzle and the PTFE film, and the upper and lower parts of the heating plate are separated by a heat shield so as not to affect the normal operation of the ultrasonic nozzle. If the spraying area is rectangular, four heating plates are used to enclose it, and the heating plate is 2cm away from the edge of the spraying surface.

[0039] 2. Preparation of catalyst slurry and preparation of catalytic layer. Choose 2 mg / cm for cathode and anode respectively 2 Pt black and 2 mg / cm 2 PtRu black catalysts, all with a solid content loading of 0.35 mg / cm 2 The 5 wt.% Nafion solution was used as the binder, both using 92.35 mg / cm 2 isopropanol and 4.85 mg / cm 2 of water as a dispersant. The glove box was evacuated and filled with N 2 gas. The catalyst was weighed in the glove box, the slurry was prepared, and the catalyst slurry was prepared by ultrasonic dispersion using an ultrason...

Embodiment 3

[0045] 1. Spray system assembly. A stainless steel heating plate is placed between the ultrasonic nozzle and the PTFE film, and the upper and lower parts of the heating plate are separated by a heat shield so as not to affect the normal operation of the ultrasonic nozzle. If the spraying area is circular, an annular heating plate is used, and the heating plate is 0.5cm away from the edge of the spraying surface.

[0046] 2. Preparation of catalyst slurry and preparation of catalytic layer. Choose 3 mg / cm for cathode and anode respectively 2 Pt black and 3 mg / cm 2 PtRu black catalysts, all with a solid content loading of 0.33 mg / cm 2 The 5 wt.% Nafion solution was used as the binder, both using 130.83 mg / cm 2 of isopropanol and 5.84 mg / cm 2 of water as a dispersant. The glove box was evacuated and filled with N 2 gas. The catalyst was weighed in the glove box, the slurry was prepared, and the catalyst slurry was prepared by ultrasonic dispersion using an ultrasonic cell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com