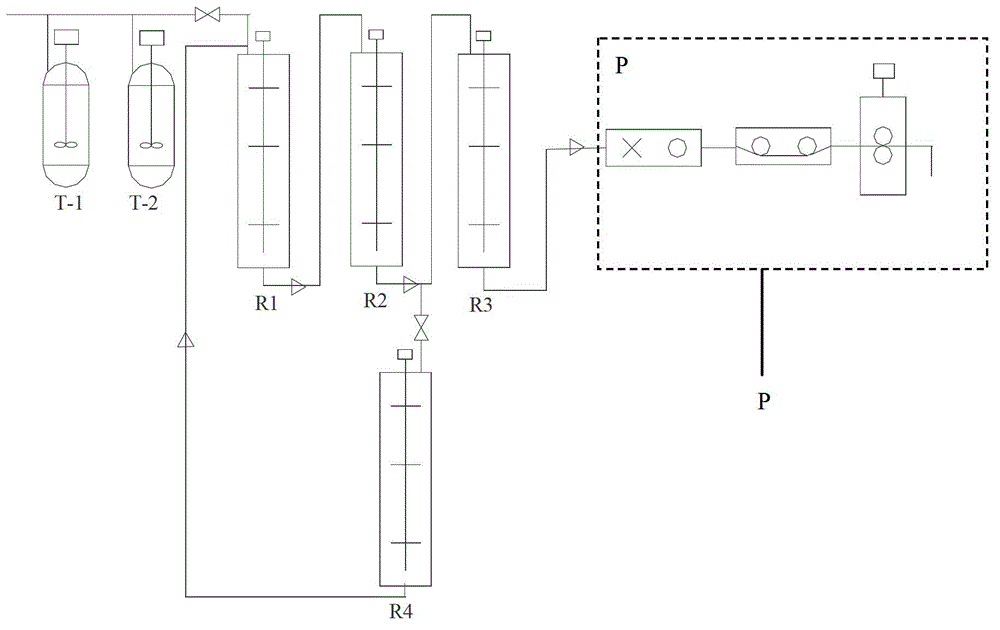

Tubular plug flow reactor with material internal circulation and preparation method for preparing continuous bulk ABS (Acrylonitrile-Butadiene-Styrene) resin

A plug flow reactor, ABS resin technology, used in the synthesis and preparation of polymer materials and synthetic resin fields, can solve the problems of poor reaction system stability, high requirements for mass transfer and heat transfer, and achieve excellent processing performance and narrow molecular weight distribution. , the effect of high impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

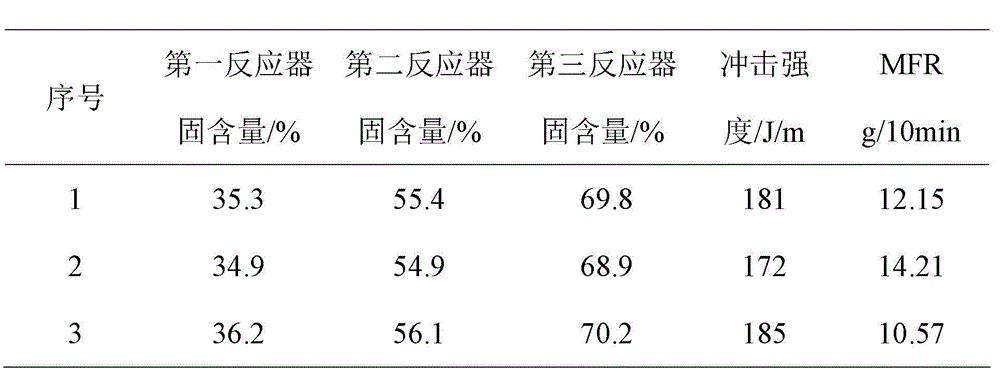

Embodiment 1

[0019] The first plug-flow reactor is a grafting reactor, and the continuous rubber phase undergoes the process of grafting SAN in this first plug-flow reactor. The percentage by weight of each component in the raw material liquid entering the grafting reactor is: styrene 63.6%, butadiene rubber 8.4%, acrylonitrile 14%, ethylbenzene 14%. The concentration of the initiator solution is 70ppm, and the flow rate is controlled at 0.7g / h. The concentration of the chain transfer agent is 45ppm, and the control flow rate is 0.5g / h.

[0020] The temperature of the upper, middle and lower zones of the first plug flow reactor is set at 102.4°C, 105.6°C, and 108.8°C, respectively.

[0021] The temperature of the upper, middle and lower zones of the second plug-flow reactor is set at 115.5°C, 118.9°C, and 123.2°C, respectively.

[0022] The temperature of the third plug flow reactor is set to be 130.5°C, 136.5°C, and 141.5°C in the upper, middle, and lower zones, respectively.

[0023] ...

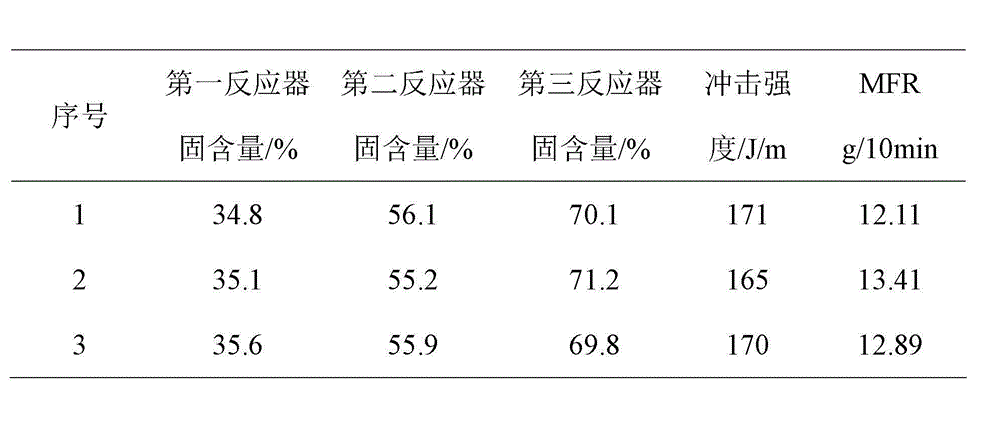

Embodiment 2

[0032] The first plug-flow reactor is a grafting reactor in which the continuous rubber phase is grafted with SAN. The weight percent of each component in the raw material liquid entering the grafting reactor is: styrene 63.6%, solution polystyrene butadiene rubber 8.4%, acrylonitrile 14%, ethylbenzene 14%. The concentration of the initiator solution is 70ppm, and the flow rate is controlled at 0.7g / h. The concentration of the chain transfer agent is 45ppm, and the control flow rate is 0.5g / h.

[0033] The temperature of the first plug flow reactor is set to be 102.4°C, 105.8°C, and 108.4°C in the upper, middle, and lower zones, respectively.

[0034] The temperature of the upper, middle and lower zones of the second plug-flow reactor is set at 115.4°C, 118.8°C, and 122.8°C, respectively.

[0035] The temperature of the third plug flow reactor is set to be 130.2°C, 134.8°C, and 140.9°C in the upper, middle, and lower zones, respectively.

[0036] The temperature of the uppe...

Embodiment 3

[0045] The first plug-flow reactor is a grafting reactor in which the continuous rubber phase is grafted with SAN. The weight percentages of each component in the raw material liquid entering the grafting reactor are: styrene 63.6%, soluble polystyrene-butadiene-isoprene ternary integrated rubber 8.4%, acrylonitrile 14%, ethylbenzene 14% %. The concentration of the initiator solution is 70ppm, and the flow rate is controlled at 0.7g / h. The concentration of the chain transfer agent is 45ppm, and the control flow rate is 0.5g / h.

[0046] The temperature of the first plug flow reactor is set to be 102.5°C, 105.6°C, and 108.1°C in the upper, middle, and lower zones, respectively.

[0047] The temperature of the upper, middle and lower zones of the second plug flow reactor is set at 115.2°C, 118.4°C, and 122.3°C, respectively.

[0048] The temperature of the upper, middle and lower zones of the third plug flow reactor is set to 130.8°C, 134.8°C, and 142.1°C respectively.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com