Method for preparing dibenzothiophene derivatives

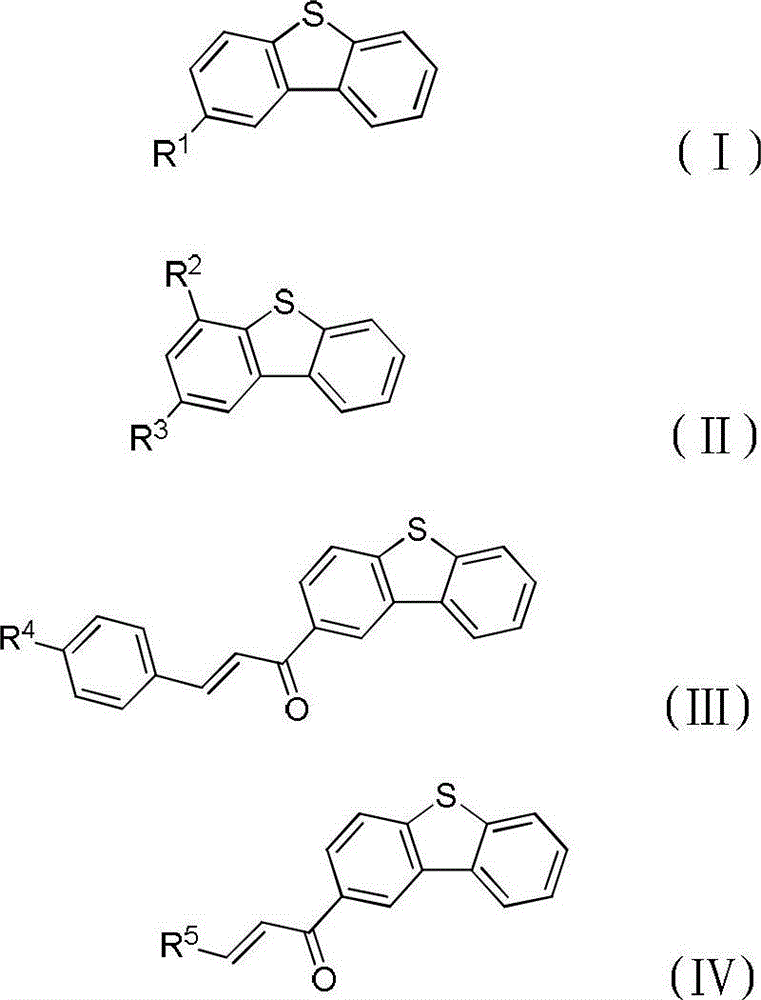

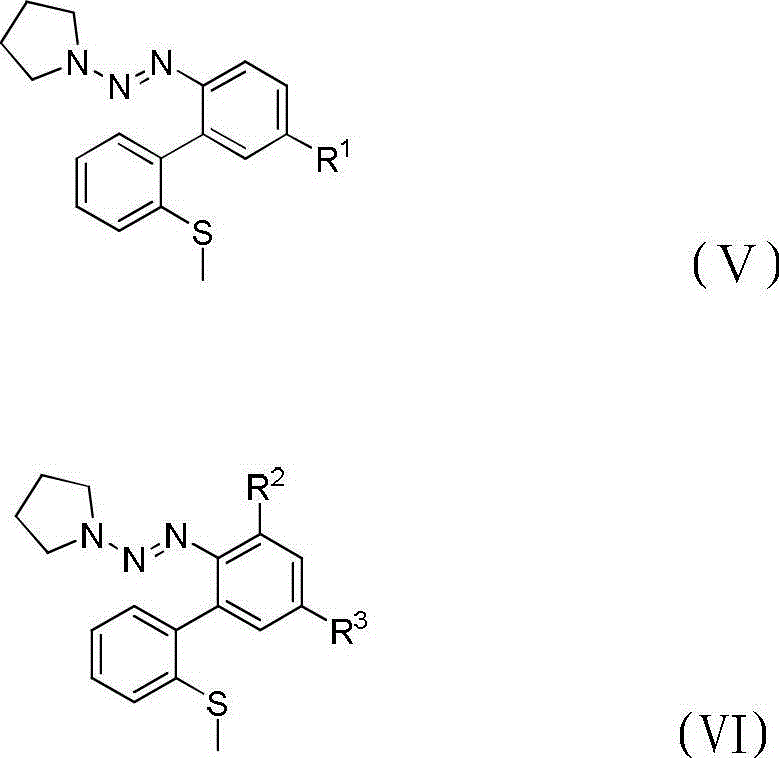

A technology for dibenzothiophene and derivatives is applied in the field of preparation of dibenzothiophene derivatives and achieves the effects of low reaction cost, simple process and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

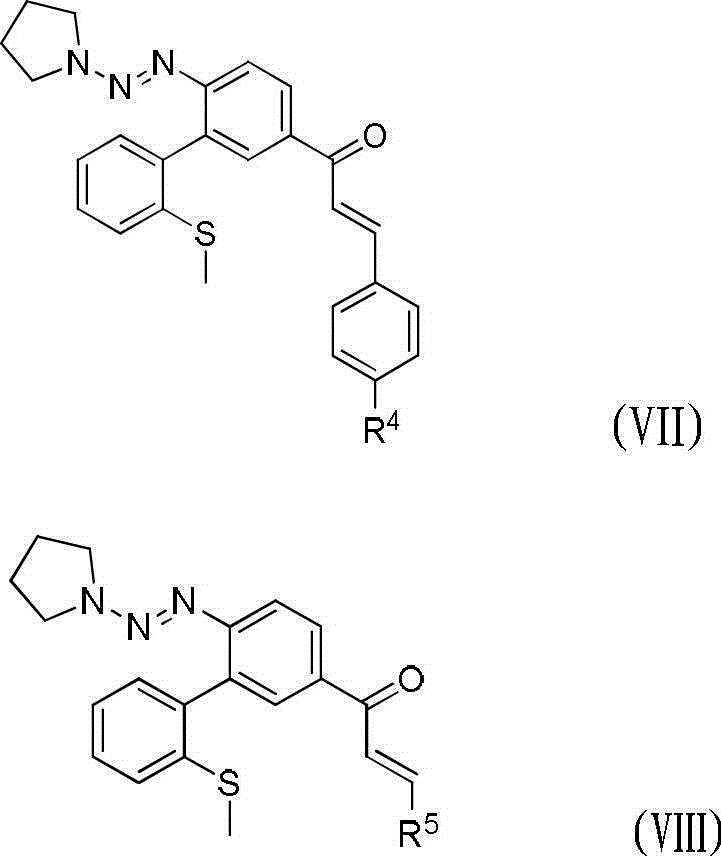

[0028] In a 100 mL reaction flask, add 369 mg of methylthio-containing triazene 1a and 40 mL of acetonitrile, and then slowly add 0.256 mL of boron trifluoride diethyl ether dropwise with a 1 mL syringe. The reaction solution was stirred at 45°C for 4 hours. After the reaction, cool to room temperature, filter with a glass funnel, and purify the filtrate through a silica gel column (the volume ratio of petroleum ether and ethyl acetate is 10:1) to obtain 215 mg of the product with a yield of 80%. The reaction process is shown in the following formula :

[0029]

[0030] The product prepared in the present embodiment is carried out nuclear magnetic resonance analysis, and the results are as follows:

[0031] 1 H NMR (400 MHz, CDCl 3 ): δ 8.84(s, 1H), 8.22-8.26(m, 1H), 8.11-8.14(m, 1H), 7.84-7.90(m, 2H), 7.48-7.51(m, 2H), 4.46(q , J=6.8Hz, 2H), 1.47(t, J=7.2Hz, 3H);

[0032] 13 C NMR (100 MHz, CDCl 3 ): δ 166.7, 144.2, 139.6, 135.5, 135.2, 127.3, 126.8, 124.8, 123.1, 1...

Embodiment 2

[0034] In a 100 mL reaction flask, add 369 mg of methylthio-containing triazene 1a and 40 mL of methanol, and then slowly add 0.256 mL of boron trifluoride diethyl ether dropwise with a 1 mL syringe. The reaction solution was stirred at 45°C for 4 hours. After the reaction, cool to room temperature, filter with a glass funnel, and purify the filtrate through a silica gel column (the volume ratio of petroleum ether and ethyl acetate is 10:1) to obtain 166 mg of the product with a yield of 65%. The reaction process is shown in the following formula :

[0035]

[0036] The product prepared in the present embodiment is carried out nuclear magnetic resonance analysis, and the results are as follows:

[0037] 1 H NMR (400 MHz, CDCl 3 ): δ 8.84(s, 1H), 8.22-8.26(m, 1H), 8.11-8.14(m, 1H), 7.84-7.90(m, 2H), 7.48-7.51(m, 2H), 4.46(q, J=6.8Hz, 2H), 1.47(t, J=7.2Hz, 3H);

[0038] 13 C NMR (100 MHz, CDCl 3 ): δ 166.7, 144.2, 139.6, 135.5, 135.2, 127.3, 126.8, 124.8, 123.1, 122.8,...

Embodiment 3

[0040] In a 100 mL reaction flask, add 369 mg of methylthio-containing triazene 1a and 40 mL of toluene, and then slowly add 0.256 mL of boron trifluoride diethyl ether dropwise with a 1 mL syringe. The reaction solution was stirred at 45°C for 4 hours. After the reaction, cool to room temperature, filter with a glass funnel, and purify the filtrate through a silica gel column (the volume ratio of petroleum ether and ethyl acetate is 10:1) to obtain 103 mg of the product with a yield of 40%. The reaction process is shown in the following formula :

[0041]

[0042] The product that present embodiment prepares is carried out nuclear magnetic resonance analysis, and the result is as follows:

[0043] 1 H NMR (400 MHz, CDCl3 ): δ 8.84(s, 1H), 8.22-8.26(m, 1H), 8.11-8.14(m, 1H), 7.84-7.90(m, 2H), 7.48-7.51(m, 2H), 4.46(q, J=6.8Hz, 2H), 1.47(t, J=7.2Hz, 3H);

[0044] 13 C NMR (100 MHz, CDCl 3 ): δ 166.7, 144.2, 139.6, 135.5, 135.2, 127.3, 126.8, 124.8, 123.1, 122.8, 122.5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com