Special catalyst for preparing o-chlorobenzonitrile by ammoxidation method and preparation method and application of catalyst

A technology of ammoxidation and o-chlorobenzonitrile, which is applied in the field of organic chemistry and organic fine chemicals, can solve the problems of rapid catalyst deactivation, unsatisfactory activity and selectivity, achieve high activity and selectivity, and reduce catalyst The effect of loss of components and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 28.62 g H 2 C 2 o 4 2H 2 O was dissolved in 100 mL of 80°C distilled water, and 8.61 g of V were added 2 o 5 and 2.84 g CrO 3 React until no gas is produced, then add 25.24 grams of Sm(NO 3 ) 3 .6H 2 O, 16.37 grams of 85% H 3 PO 4 , 1.47 g H 3 BO 3 and 0.32 g K 2 CO 3 After forming a uniform solution, slowly add 100 mL of 30% silica sol, and then add 5 g of aminohexyltrichlorosilane. After stirring evenly, the catalyst precursor was obtained by high-speed spray centrifugal drying, dried in a muffle furnace at 110° C., and then gradually raised to 550° C. for 6 hours. After natural cooling, set aside. The active composition of the catalyst is: VP 1.5 SM 0.6 Cr 0.3 B 0.25 K 0.05 .

[0024] 20g of the above-mentioned solid catalysts are filled in a quartz tube fixed-bed reactor with an internal diameter of 30mm, and the molar ratio of the reaction raw materials is: o-chlorotoluene:NH 3 :Air=1:3:20, the reaction temperature is 673±1K, and the catalyst ...

Embodiment 2~8

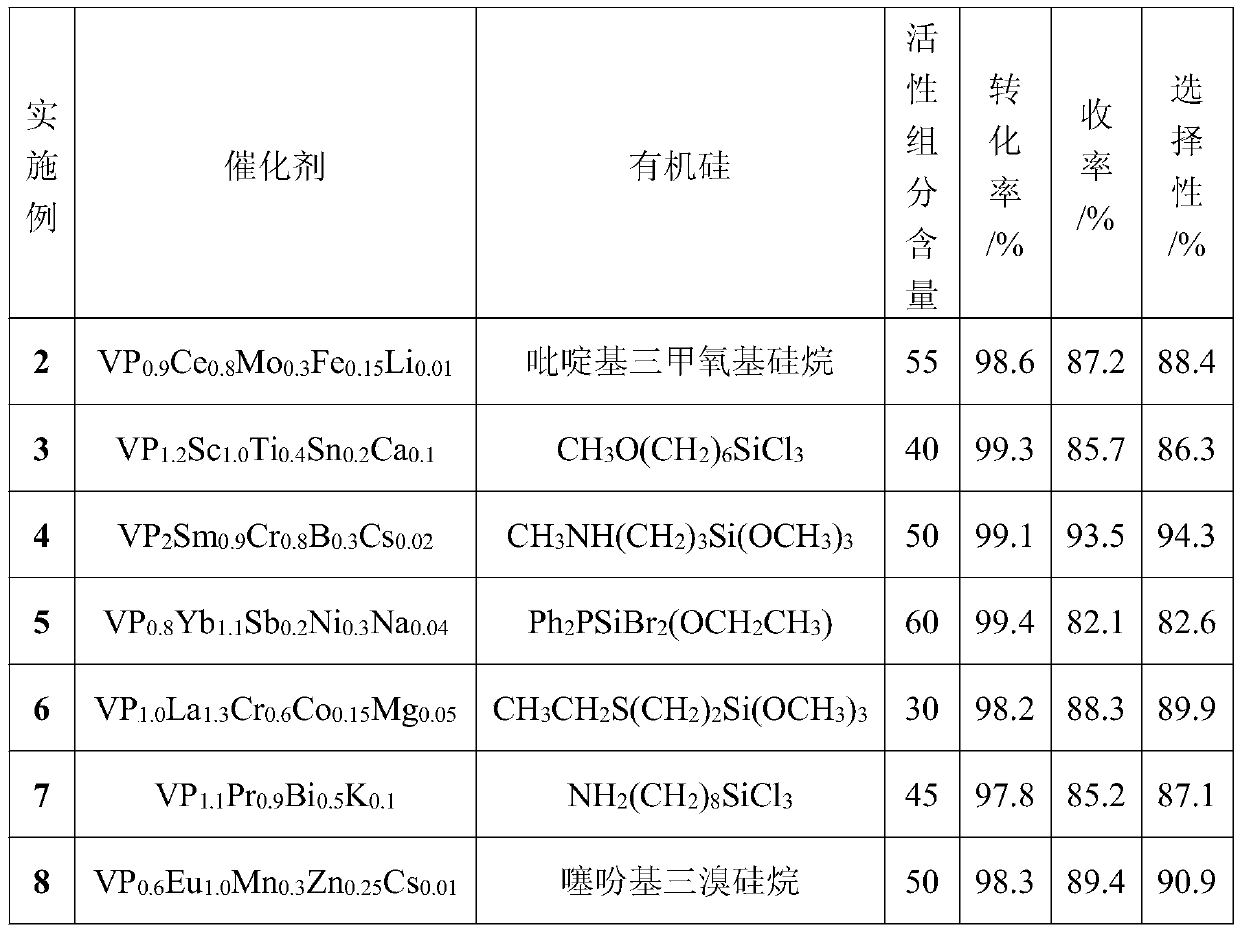

[0026] Catalyst formula is different, and reaction condition is with embodiment 1, and result is as follows:

[0027]

[0028] The catalyst of the present invention containing other co-catalysts can be prepared according to the above method, wherein the corresponding precursors can be oxides, salts, acids or bases of other co-catalyst components. During the preparation, the desired catalyst can be obtained by replacing the corresponding precursor substances in proportion with reference to the above-mentioned examples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com