Method for selective hydrogenation of methyl-alpha-methyl styrene

A technology of methyl styrene and selective hydrogenation, which is applied in the fields of hydrogenation to hydrocarbons, organic chemistry, etc., can solve the problems of frequent addition of fresh catalysts, complicated hydrogenation process, undesired by-products, etc., and achieves low catalyst cost and high activity. , mild effect of hydrogenation reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

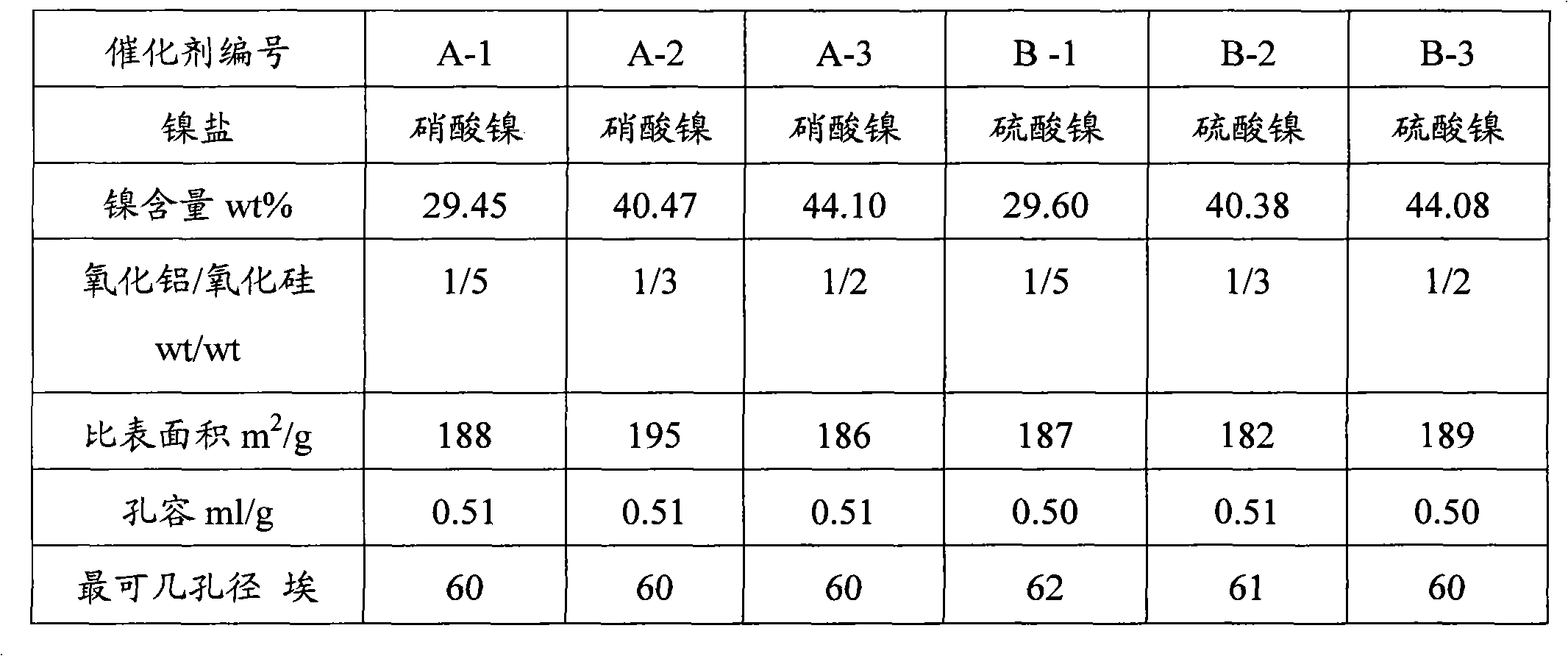

[0023] 2000 milliliters of mixed glue solution that is respectively 20.6 grams of aluminum sulfate and 103.0 grams of sodium silicate (aluminum oxide / silicon oxide weight ratio is 1 / 5) in terms of aluminum oxide and silicon oxide, at a temperature of 50 ° C and a pH value of 6.0. Under normal pressure and strong stirring conditions, add 1000 ml of nickel nitrate aqueous solution with a content of 76.4 g in terms of nickel oxide to the above mixed glue, settle for 30 minutes, filter, and use 10 times the volume of the filter cake with deionized water Wash for 40 minutes, filter, wash again, filter again, and this process is repeated four times.

[0024] The filter cake was dried at 100°C for 10 hours, calcined at 450°C for 8 hours, cooled to room temperature, ground into powder, and punched into flakes to obtain catalyst A-1 of the present invention. See Table 1 for the data.

Embodiment 2

[0026] 2000 milliliters of mixed glue solution that is respectively 24.55 grams of aluminum sulfate and 73.64 grams of sodium silicate (aluminum oxide / silicon oxide weight ratio is 1 / 3) in terms of alumina and silica, at a temperature of 60 ° C and a pH value of 7.0. Under normal pressure and strong stirring conditions, add 1000 ml of nickel nitrate aqueous solution with a content of 101.81 g in terms of nickel oxide to the above mixed glue, settle for 30 minutes, filter, and use 10 times the volume of the filter cake with deionized water Wash for 40 minutes, filter, wash again, filter again, and this process is repeated four times.

[0027] The filter cake was dried at 100° C. for 10 hours, calcined at 500° C. for 5 hours, cooled to normal temperature, ground into powder, and made into a column to obtain catalyst A-2 of the present invention. See Table 1 for the data.

Embodiment 3

[0029] 2000 milliliters of mixed glue solution with a content of 28.49 grams of aluminum sulfate and 56.98 grams of sodium silicate (alumina / silicon oxide weight ratio is 1 / 2) in terms of alumina and silica, at a temperature of 70 ° C and a pH value of 6.0 , under normal pressure and strong stirring conditions, 1000 ml of nickel nitrate aqueous solution with a content of 114.53 grams in terms of nickel oxide was added to the above-mentioned alumina-silica gel solution, precipitated for 40 minutes, filtered, and removed with 20 times the volume of the filter cake. Wash with deionized water for 40 minutes, filter, wash again, and filter again, and this process is repeated four times.

[0030] The filter cake was dried at 100° C. for 10 hours, calcined at 500° C. for 5 hours, cooled to normal temperature, ground into powder, and punched into flakes to obtain catalyst A-3 of the present invention. See Table 1 for the data.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com