Loaded nickel-indium (Ni-In) intermetallic compound catalyst and preparation method thereof

An intermetallic compound, supported technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, hydroxyl compound preparation, organic compound preparation, etc. It is difficult to prepare compounds with small particle size and other problems, so as to achieve the effects of convenient industrial production, high yield and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

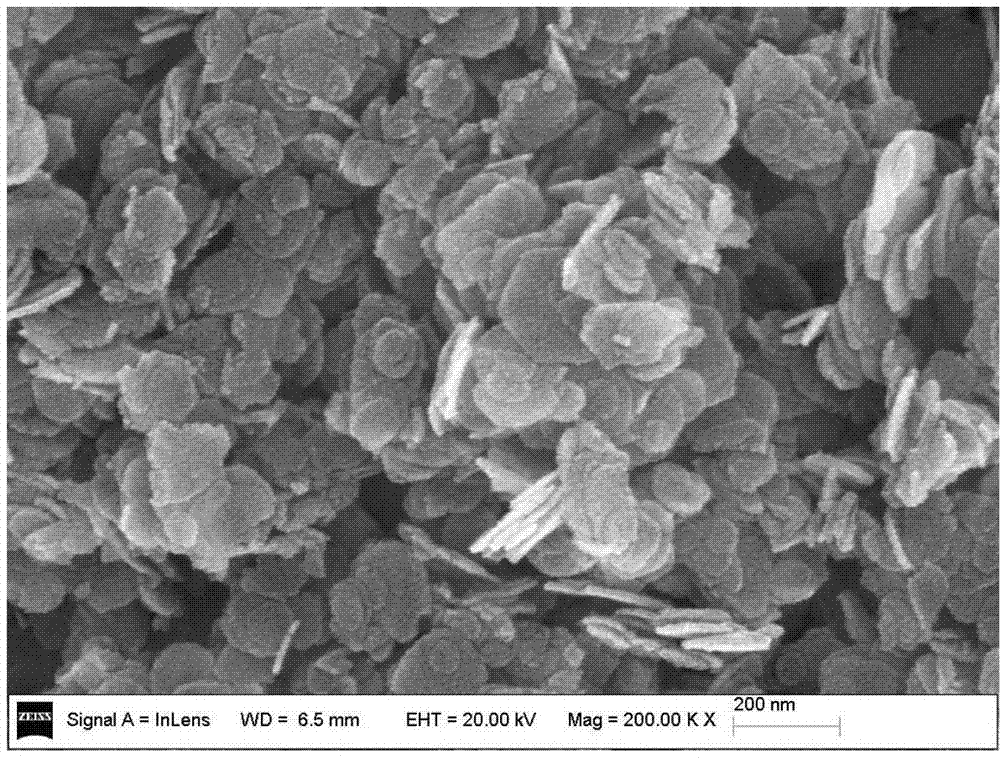

[0021] Weigh 2.91g of nickel nitrate, 1.50g of indium nitrate, and 1.88g of aluminum nitrate, dissolve them into 100ml of pure water to form a uniformly dispersed solution, and weigh 1.44g of sodium hydroxide and 2.12g of sodium carbonate into 100ml of pure water to form Alkaline solution, the two solutions were uniformly mixed in a colloid mill at a speed of 3000r / min for 2 minutes to form a suspension, the suspension was poured into a hydrothermal kettle, placed in a 120°C oven for 24 hours, taken out, centrifuged and washed, 60 ℃ oven-dried, ground into Ni 2 AlIn-LDHs powder; then Ni 2 Put the AlIn-LDHs powder into a quartz boat, put it into an atmosphere furnace, and in a hydrogen atmosphere, raise the temperature to 450°C at a heating rate of 2°C / min, and keep it for 5h to prepare the supported Ni 2 In / Al 2 o 3 Intermetallic catalysts.

[0022] The supported Ni prepared above 2 In / Al 2 o 3 The intermetallic compound catalyst is prepared by using hydrotalcite as a p...

Embodiment 2

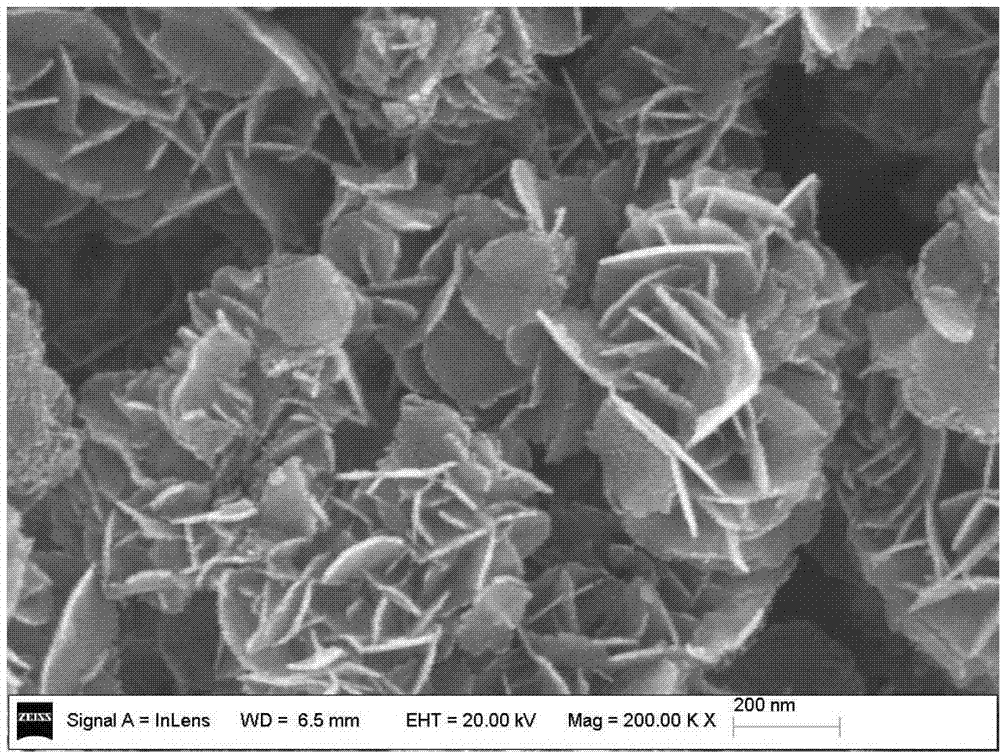

[0025] Weigh 1.45g of nickel nitrate, 1.50g of indium nitrate, and 2.56g of magnesium nitrate, and dissolve them into 100ml of pure water to form a uniformly dispersed solution; another weigh 1.44g of sodium hydroxide and 1.06g of sodium carbonate into 100ml of pure water to form alkaline solution. The two solutions were uniformly mixed for 1 min at a high speed of 3000 r / min in a colloid mill to form a suspension. Pour the suspension into a hydrothermal kettle, place it in an oven at 120°C for 24 hours, take it out, wash it by centrifugation, dry it in an oven at 60°C, and grind it into NiMg 2 In-LDHs powder is ready for use. NiMg 2 Put the In-LDHs hydrotalcite precursor into a quartz boat, put it into an atmosphere furnace, and in a hydrogen atmosphere, raise the temperature to 450°C at a heating rate of 2° / min and keep it for 5h to prepare a highly dispersed NiIn / MgO intermetallic compound catalyst.

[0026] The supported NiIn / MgO intermetallic compound catalyst prepare...

Embodiment 3

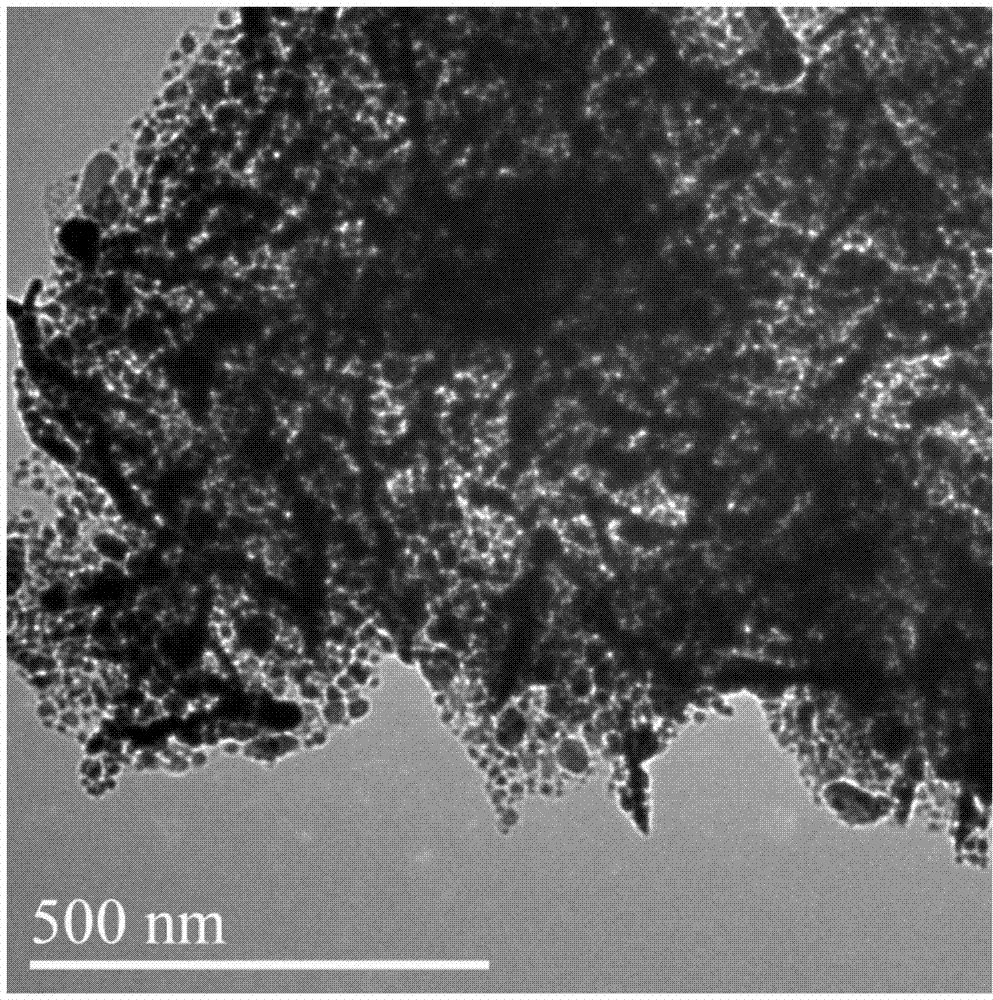

[0029] Weigh 0.96g of nickel nitrate, 1.50g of indium nitrate, and 3.00g of magnesium nitrate, dissolve them in 100ml of pure water to form a uniformly dispersed solution, and dissolve 1.44g of sodium hydroxide and 1.06g of sodium carbonate into 100ml of pure water to form an alkali Solution, the two solutions were uniformly mixed in a colloid mill at a speed of 3000r / min for 1min to form a suspension, the suspension was poured into a hydrothermal kettle, placed in a 120°C oven for 24h, taken out, centrifuged and washed at 60°C Oven dried and ground to Ni 2 Mg 7 In 3 -LDHs powder; then Ni 2 Mg 7 In 3 - Put the LDHs powder into a quartz boat, put it into an atmosphere furnace, and raise the temperature to 450°C at a heating rate of 2°C / min in a hydrogen atmosphere, and keep it for 5h to prepare a supported Ni 2 In 3 / MgO intermetallic compound catalyst.

[0030] The supported Ni prepared above 2 In 3 / MgO intermetallic compound catalyst, which uses hydrotalcite as the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com