A carbon-supported noble metal nanoparticle composite material and its preparation method and application

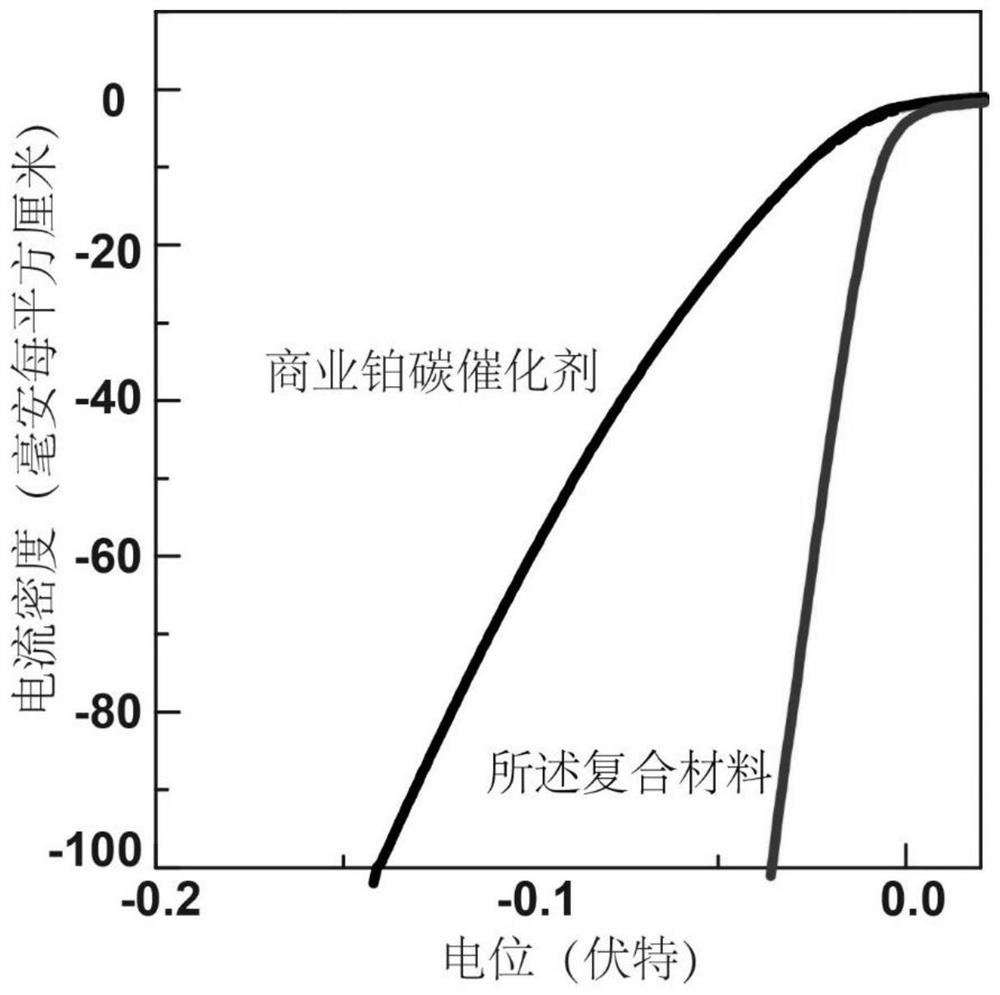

A nanoparticle and composite material technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the control of metal nanoparticle size, dispersion and loading Difficulty, limiting the effective expression of catalytic activity, reducing catalyst activity and other problems, to achieve excellent catalytic performance, broad industrial application prospects, and the effect of reducing overpotential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

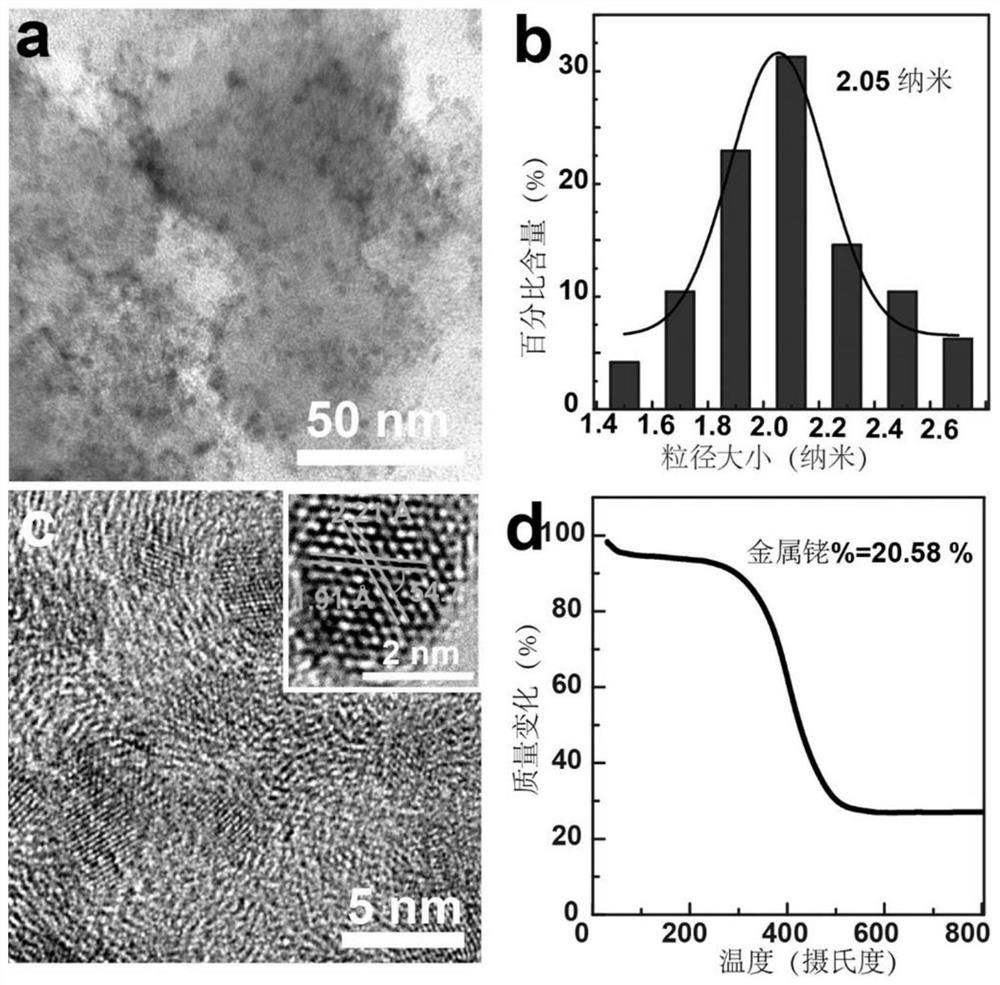

[0044] Embodiment 1, preparation conductive carbon supported precious metal rhodium nanoparticle composite material

[0045] Prepare carbon-loaded noble metal rhodium nanoparticle composites according to the following steps: (1) 30 mg of conductive carbon (XC-72R Vulcan carbon; specific surface area is 254.0 square meters per gram) purchased from Sigma Company and 27 mg purchased from Kunming Platinum The company's rhodium trichloride hydrate is added to the mortar, and after grinding evenly, sodium hydroxide purchased from Aladdin Company is added according to the molar ratio of sodium hydroxide and rhodium trichloride at 4:1, and sodium borohydride and precious metal The molar ratio of the precursor salt is 4:1, adding sodium borohydride purchased from Alpha Company, and after grinding for 30 minutes, the carbon-loaded noble metal rhodium nanoparticle composite material is initially prepared, and finally the above-mentioned prepared material is washed and dried, namely The c...

Embodiment 2

[0051] Embodiment 2, preparation conductive carbon supported precious metal rhodium nanoparticle composite material

[0052] Prepare conductive carbon supported precious metal rhodium nanoparticle composite material substantially according to the same method as Example 1, difference is: the amount of rhodium trichloride hydrate, sodium hydroxide and sodium borohydride in step (1) increases respectively To 2 times in Example 1.

[0053] The thermogravimetric curve of the carbon-supported noble metal rhodium nanoparticle composite material prepared in this embodiment is as follows Figure 4 shown. It can be seen from the analysis of the thermogravimetric curve that the mass percentage of the noble metal rhodium in the carbon-supported noble metal rhodium nanoparticle composite material prepared in this example is 35.71%.

Embodiment 3

[0054] Embodiment 3, preparation conductive carbon supported precious metal rhodium nanoparticle composite material

[0055] Prepare conductive carbon supported precious metal rhodium nanoparticle composite material substantially according to the same method as Example 1, difference is: the amount of rhodium trichloride hydrate, sodium hydroxide and sodium borohydride in step (1) is respectively reduced To 0.5 times in Example 1.

[0056] The thermogravimetric curve of the carbon-supported noble metal rhodium nanoparticle composite material prepared in this embodiment is as follows Figure 4 shown. It can be seen from the analysis of the thermogravimetric curve that the mass percentage of the noble metal rhodium in the carbon-supported noble metal rhodium nanoparticle composite material prepared in this example is 5.59%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com