Fluidized bed hydrogenation and heavy oil catalytic cracking combining method and hydrogenation catalyst

A hydrogenation catalyst and heavy oil catalysis technology, which is applied in the field of heavy oil deep processing, can solve the problems of poor cracking performance, low cracking rate, and low economic benefits, and achieve the effects of small cracking rate, reduced cracking rate, and extended operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

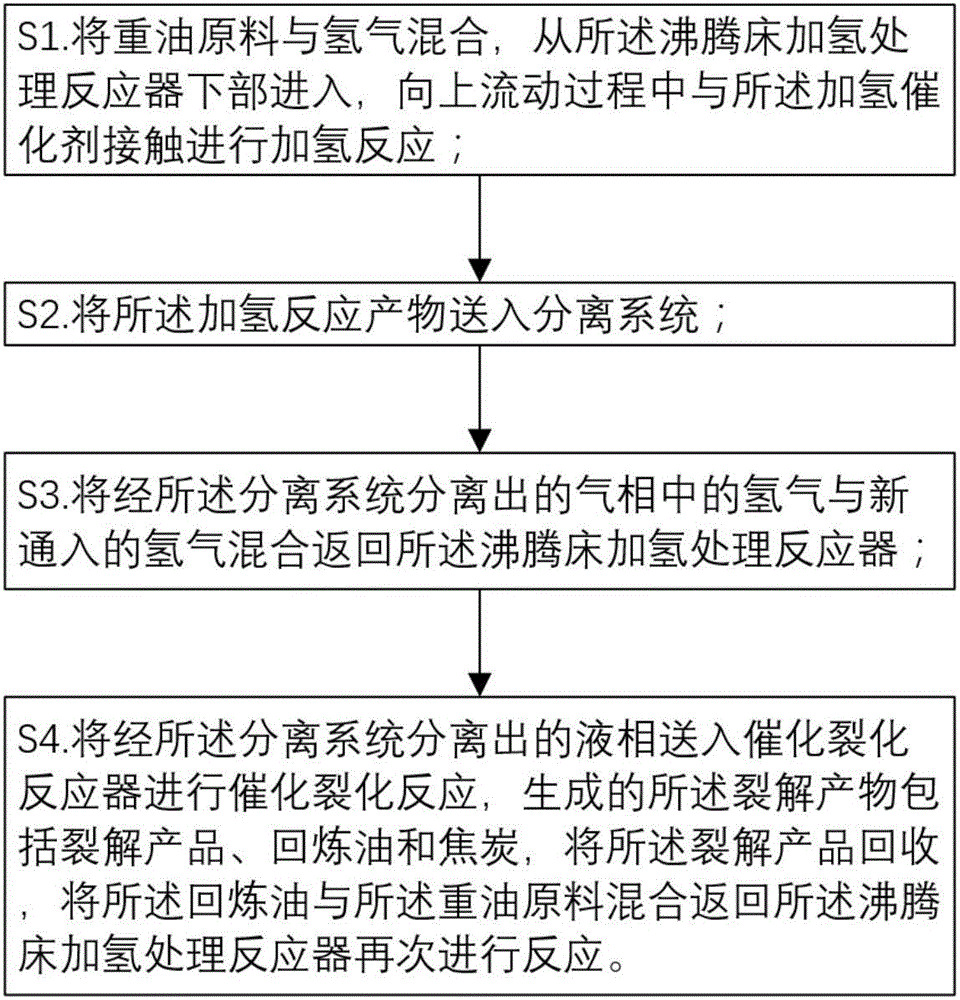

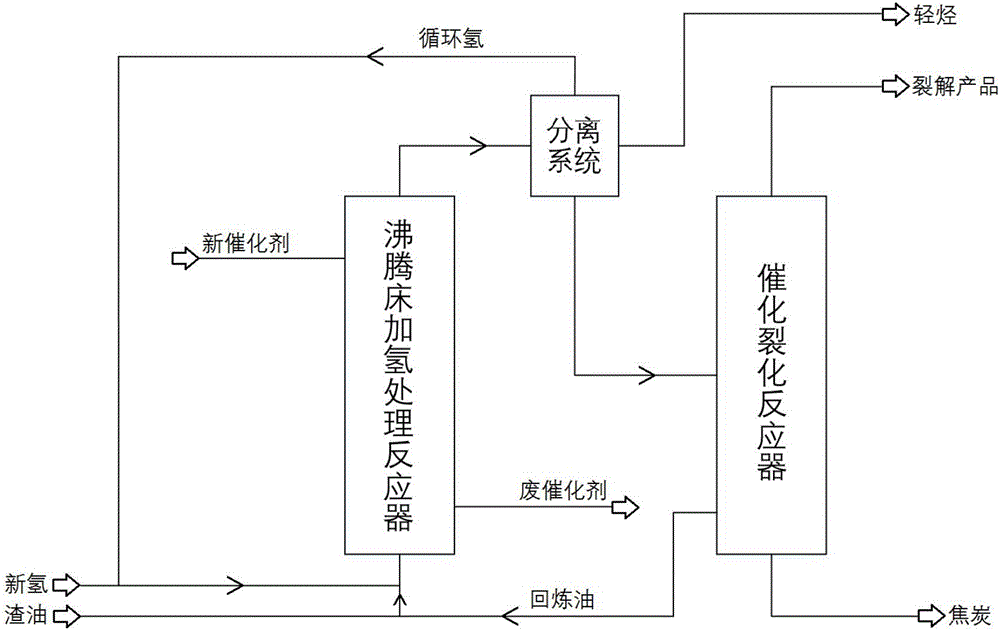

[0044] A new fluidized bed hydrogenation and heavy oil catalytic cracking combined process, the process flow is as follows figure 2 shown. The combined process of fluidized bed hydrogenation and heavy oil catalytic cracking is used to process inferior heavy oil. The specific steps are:

[0045] The raw material of heavy oil, whose properties are shown in Table 1, is mixed with catalytic cracking oil refining, mixed with hydrogen, enters the ebullating bed hydrotreating reactor from the lower part, and contacts with a special hydrogenation catalyst. The catalyst composition is shown in Table 2, forming an ebullating fluidized bed. The hydrogenation saturation reaction of polycyclic aromatic hydrocarbons is carried out, and the reaction conditions of ebullated bed heavy oil hydrotreating are shown in Table 3, and the reactions of hydrodemetallization, hydrodesulfurization, hydrodenitrogenation and hydrodecarbonization are carried out at the same time.

[0046] Table 1. Propert...

Embodiment 2

[0063] The process flow, catalyst and raw materials of Example 2 are the same as in Example 1. The reaction conditions of ebullated bed hydrotreating are shown in Table 7, the properties of products of ebullated bed heavy oil hydrotreating are shown in Table 8, and the reaction conditions of catalytic cracking are shown in Table 9. The catalytic cracking products The distribution is shown in Table 10.

[0064] Table 7. Ebullated bed hydrotreating reaction conditions:

[0065]

[0066]

[0067] Table 8. Properties of ebullated bed heavy oil hydrotreating products:

[0068]

[0069] Table 9. Catalytic cracking reaction conditions:

[0070] project value project value Reaction temperature (°C) 550~580 Reaction pressure (kPaG) 80~150

[0071] Table 10. FCC product distribution:

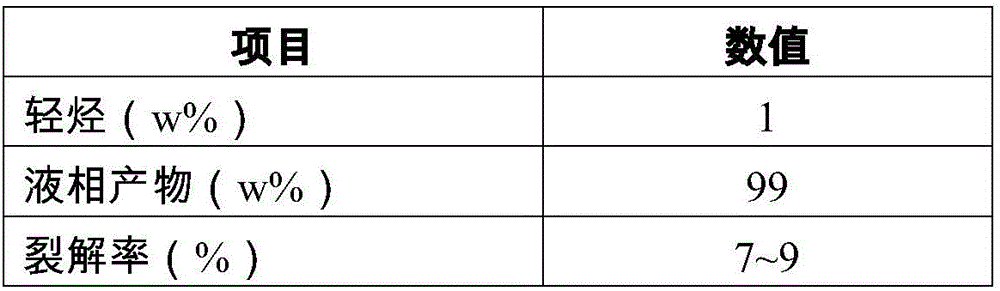

[0072] project value Dry gas (w%) 2.35 Liquid hydrocarbon (w%) 22.5 Gasoline fraction (38~187℃,w%) 46.6 Diesel fraction (187~370...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com