Clopidogrel hydrogen sulfate tablet and preparation method thereof

A technology of clopidogrel hydrogen sulfate tablets and clopidogrel hydrogen sulfate is applied in the directions of pharmaceutical formulations, medical preparations without active ingredients, medical preparations containing active ingredients, etc. Large-scale production, easy sticking and punching of tablets, etc., to achieve the effect of easy industrialization, reducing sticking and punching, and solving easy sticking and punching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

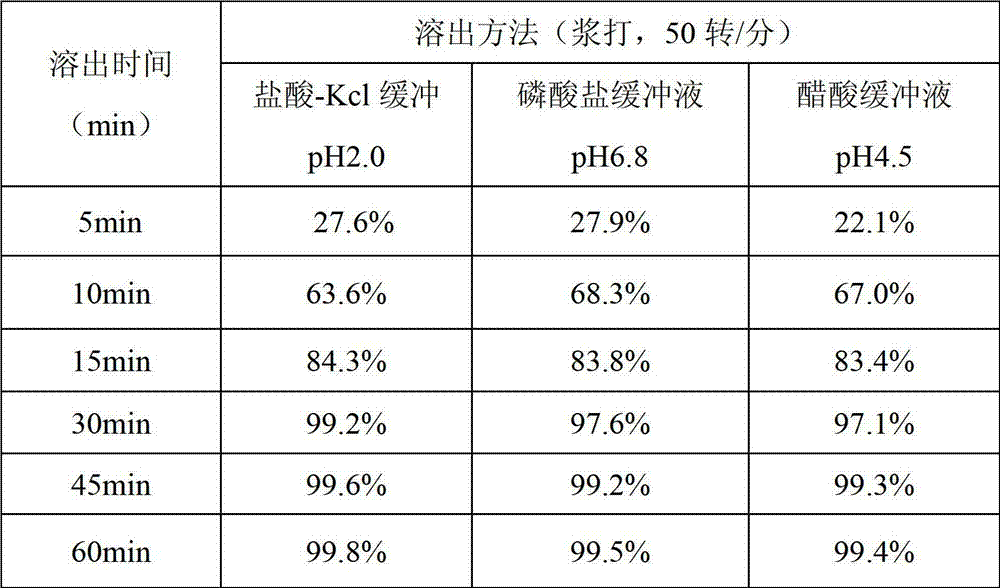

Image

Examples

Embodiment 1

[0019] The clopidogrel bisulfate tablet of this embodiment comprises the following components by mass: 39.44 parts of clopidogrel bisulfate, 31.53 parts of lactose, 15 parts of pregelatinized starch, 10 parts of microcrystalline cellulose, 6000 parts of polyethylene glycol 2.7 parts, 1.33 parts of hydrogenated castor oil, 3 parts of coating film.

[0020] The preparation method of the clopidogrel bisulfate tablet provided in this example (the weight of the tablet core is 248 mg, taking the preparation of 1000 tablets as an example), comprises the following steps:

[0021] 1) Dry microcrystalline cellulose and pregelatinized starch at 80°C until the water content is <3% and <14% respectively; then pass clopidogrel bisulfate through a 40-mesh sieve, polyethylene glycol 6000 through a 100-mesh sieve, spare;

[0022] 2) Mix 97.8g of clopidogrel bisulfate, 78.204g of lactose, 24.8g of microcrystalline cellulose, 12.4g of pregelatinized starch and 3.348g of polyethylene glycol 6000...

Embodiment 2

[0028] The clopidogrel bisulfate tablet of this embodiment comprises the following components by mass: 39.44 parts of clopidogrel bisulfate, 31.53 parts of lactose, 15 parts of pregelatinized starch, 10 parts of microcrystalline cellulose, 6000 parts of polyethylene glycol 2.7 parts, 1.33 parts of hydrogenated castor oil, 3 parts of coating film.

[0029] The preparation method of the clopidogrel bisulfate tablet provided in this example (the weight of the tablet core is 248 mg, taking the preparation of 1000 tablets as an example), comprises the following steps:

[0030] 1) Dry microcrystalline cellulose and pregelatinized starch at 80°C until the water content is <3% and <14% respectively; then pass clopidogrel bisulfate through a 40-mesh sieve, polyethylene glycol 6000 through a 100-mesh sieve, spare;

[0031] 2) Mix 97.8g of clopidogrel bisulfate, 78.204g of lactose, 24.8g of microcrystalline cellulose, 12.4g of pregelatinized starch and 3.348g of polyethylene glycol 6000...

Embodiment 3

[0037] The clopidogrel bisulfate tablet of this embodiment includes the following components by mass: 39.44 parts of clopidogrel bisulfate, 31.53 parts of lactose, 15 parts of pregelatinized starch, 10 parts of microcrystalline cellulose, 6000 parts of polyethylene glycol 2.7 parts, 1.33 parts of hydrogenated castor oil, 3 parts of coating film.

[0038] The preparation method of the clopidogrel bisulfate tablet provided in this example (the weight of the tablet core is 248 mg, taking the preparation of 1000 tablets as an example), comprises the following steps:

[0039] 1) Dry microcrystalline cellulose and pregelatinized starch at 80°C until the water content is <3% and <14% respectively; then pass clopidogrel bisulfate through a 40-mesh sieve, polyethylene glycol 6000 through a 100-mesh sieve, spare;

[0040] 2) Mix 97.8g of clopidogrel hydrogen sulfate, 78.204g of lactose, 24.8g of microcrystalline cellulose, 12.4g of pregelatinized starch and 60003.348g of polyethylene g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com