Method for squeezing and refining walnut oil at low temperature

A technology of walnut oil and low temperature is applied in the field of low temperature pressing and refining of walnut oil, which can solve the problems of increased workload and production cost, decreased quality of walnut oil, loss of trace elements, etc. The effect of less energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

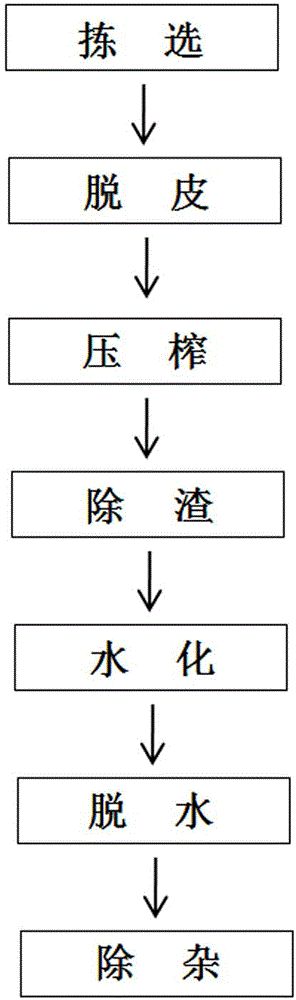

Image

Examples

Embodiment 1

[0034] First, select the walnut kernels, remove the deteriorated walnut kernels and foreign matter, and make the impurity content ≤ 5%. Then, soak the walnut kernels in 0.6% dilute sodium hydroxide solution at 70°C for 10 minutes, and then rinse the walnut kernels with cold water. The peeled walnuts are dried in a mixed-flow hot air dryer to a moisture content of 10%. The dried walnut kernels are subpackaged into 4kg small packages, and put into the mold of the vertical cylinder hydraulic oil press, and each material layer is separated by a thin iron sheet. Pressing at room temperature, using segmented boosting method, the boosting speed of the pre-pressing section with a pressure ≤ 10MPa is 4MPa / min, the boosting speed of the oil outlet section with a pressure of 11-20MPa is 2MPa / min, and the draining section with a pressure of 21-40MPa The pressure increase speed is 3MPa / min, and the pressure is released after the pressure rises to 40MPa. Put the squeezed walnut oil aside ...

Embodiment 2

[0036] First, select the walnut kernels, remove the deteriorated walnut kernels and foreign matter, and make the impurity content ≤ 5%. Then, soak the walnut kernels in 0.5% dilute sodium hydroxide solution at 80°C for 15 minutes, and then rinse the walnut kernels with cold water. The peeled walnut kernels are dried in a vacuum constant temperature dryer to a moisture content of 8%. The dried walnut kernels are subpackaged into 6kg small packages, and put into the mold of the vertical cylinder hydraulic oil press, and each material layer is separated by a thin iron sheet. Pressing at room temperature, using segmented boosting method, the boosting speed of the pre-pressing section with a pressure ≤ 10MPa is 4MPa / min, the boosting speed of the oil outlet section with a pressure of 11-20MPa is 2MPa / min, and the draining section with a pressure of 21-40MPa The pressure increase speed is 3MPa / min, and the pressure is released after the pressure rises to 40MPa. Centrifuge the fres...

Embodiment 3

[0038]First, select the walnut kernels, remove the deteriorated walnut kernels and foreign matter, and make the impurity content ≤ 5%. Then, soak the walnut kernels in 0.4% dilute potassium hydroxide solution at 90°C for 20 minutes, and then rinse the walnut kernels with cold water. The peeled walnut kernels are dried in a continuous disc dryer to a moisture content of 6%. The dried walnut kernels are subpackaged into 8kg small packages, and put into the mold of the vertical cylinder hydraulic oil press, and each material layer is separated by a thin iron sheet. Pressing at room temperature, using segmented boosting method, the boosting speed of the pre-pressing section with a pressure ≤ 10MPa is 4MPa / min, the boosting speed of the oil outlet section with a pressure of 11-20MPa is 2MPa / min, and the draining section with a pressure of 21-40MPa The pressure increase speed is 3MPa / min, and the pressure is released after the pressure rises to 40MPa. Centrifuge the freshly squeez...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com