Polishing solution and method for polishing cadmium sulfide (CdS) wafer by applying same

A polishing liquid and wafer technology, which is applied to polishing compositions containing abrasives, grinding devices, grinding machine tools, etc., can solve the problems of poor polishing effect and large surface roughness of CdS single crystal, and achieve easy operation and cleaning. , the effect of small damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

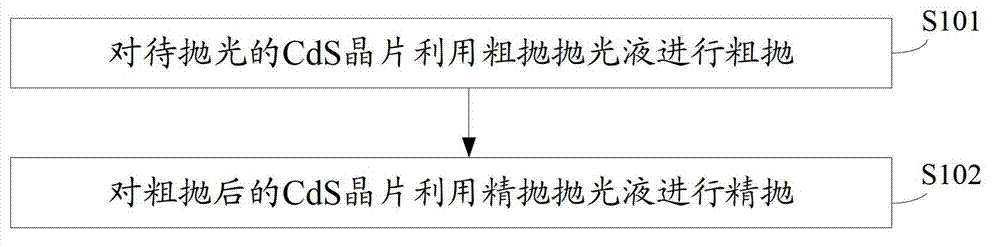

Method used

Image

Examples

Embodiment 1

[0024] The embodiment of the present invention provides a kind of polishing liquid for chemical mechanical polishing, and this polishing liquid comprises:

[0025] The polishing fluid comprises a polishing fluid for rough polishing and a polishing fluid for precise polishing; wherein:

[0026] The polishing liquid for the rough polishing comprises: 5-10wt% of nano-abrasives, 1.5-3wt% of an oxidant, 0.01wt% of a surfactant, a pH regulator, and the balance is deionized water, the particle size is 20-50nm, and the pH is 9.5;

[0027] The polishing liquid for fine polishing includes: 1-5wt% of nano-abrasives, 0.5-1.5wt% of oxidizing agent, 0.01wt% of surfactant, pH regulator, the balance is deionized water, particle size is 10-30nm, pH value is 9.5.

[0028] Wherein, the nano-abrasive includes silicon dioxide, or a mixture of silicon dioxide and cerium oxide, and when the nano-abrasive is silicon dioxide and cerium oxide, the weight ratio of silicon dioxide to cerium oxide is gr...

Embodiment 2

[0033] The embodiment of the present invention provides a kind of polishing liquid for chemical mechanical polishing, and this polishing liquid comprises:

[0034] The polishing fluid comprises a polishing fluid for rough polishing and a polishing fluid for precise polishing; wherein:

[0035] The polishing liquid for rough polishing includes: 5wt% silicon dioxide, 1.5wt% sodium hypochlorite, 0.01wt% fatty alcohol polyoxyethylene ether, pH regulator, the balance is deionized water, the particle size is 20nm, and the pH value is 9.5 ;

[0036] The polishing liquid for fine polishing includes: 1wt% of silicon dioxide, 0.5wt% of sodium hypochlorite, 0.01wt% of fatty alcohol polyoxyethylene ether, pH regulator, the balance is deionized water, the particle size is 10nm, and the pH value is 9.5 .

[0037] Wherein, the pH regulator includes an inorganic solution and an organic solution, the volume ratio of the inorganic solution to the organic solution is 1:1, the inorganic solutio...

Embodiment 3

[0040] The embodiment of the present invention provides a kind of polishing liquid for chemical mechanical polishing, and this polishing liquid comprises:

[0041] The polishing fluid comprises a polishing fluid for rough polishing and a polishing fluid for precise polishing; wherein:

[0042] The polishing liquid for the rough polishing includes: 10wt% of silicon dioxide, 3wt% of sodium hypochlorite, 0.01wt% of polyoxyethylene amide, a pH regulator, and the balance is deionized water, the particle size is 50nm, and the pH value is 9.5;

[0043] The polishing liquid for fine polishing includes: 5wt% of silicon dioxide, 1.5wt% of sodium hypochlorite, 0.01wt% of polyoxyethylene amide, pH regulator, the balance is deionized water, the particle size is 30nm, and the pH value is 9.5.

[0044] The pH regulator includes an inorganic solution and an organic solution, wherein the volume ratio of the inorganic solution to the organic solution is 1:5, the inorganic solution is potassium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com