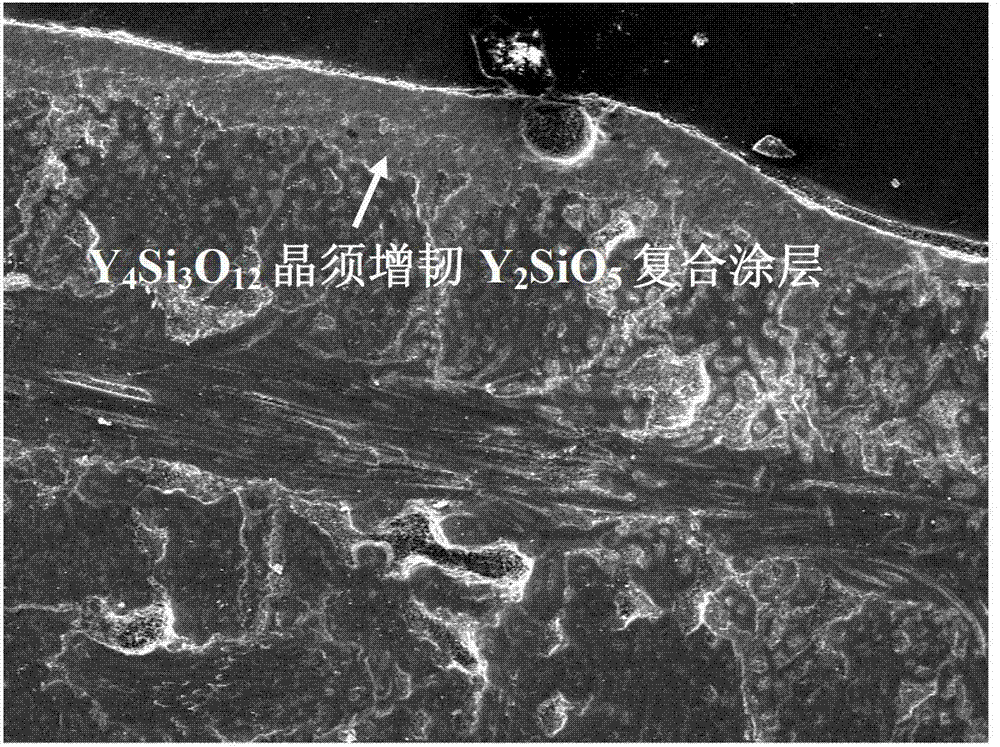

Preparation method of Y4Si3O12 whisker toughened Y2SiO5 composite coating

A composite coating and whisker technology, which is applied in the field of C/C composite materials, can solve the problems of easy falling off and oxidation protection time, failure to reach, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step 1: C / C composite material pretreatment:

[0030] 1) Take the 2D-carbon / carbon composite material used for aircraft brake pads and process it into 35×35×35mm 3 The cube, and its surface treatment of grinding and chamfering, the chamfering is 30°;

[0031] 2) Then use deionized water and absolute ethanol to ultrasonically clean 4 times respectively, the ultrasonic time for each cleaning is 10min, the ultrasonic power is 80W, and finally dry in an electric blast drying oven at 50°C.

[0032] Step 2: Prepare SiC porous inner coating on the surface of C / C composite substrate by embedding method

[0033] 1) First, take commercially available analytically pure Si powder, C powder and B powder with a particle size of 20-30 μm 2 o 3 Powder, according to Si powder: C powder: B 2 o 3 Powder = 3:5:0.5 mass ratio to prepare embedding powder, then put the pretreated carbon / carbon composite material into a graphite crucible, and embed it in the embedding powder;

[0034] 2)...

Embodiment 2

[0047] Step 1: C / C composite material pretreatment:

[0048] 1) Take the 2D-carbon / carbon composite material used for aircraft brake pads and process it into 38×38×38mm 3The cube, and its surface treatment of grinding and chamfering, the chamfering is 35°;

[0049] 2) Then use deionized water and absolute ethanol to ultrasonically clean 3 times respectively, the ultrasonic time of each cleaning is 20min, the ultrasonic power is 100W, and finally dry in an electric blast drying oven at 55°C.

[0050] Step 2: Prepare SiC porous inner coating on the surface of C / C composite substrate by embedding method

[0051] 1) First, take commercially available analytically pure Si powder, C powder and B powder with a particle size of 20-30 μm 2 o 3 Powder, according to Si powder: C powder: B 2 o 3 Powder = 4:4:0.8 mass ratio to prepare embedding powder, then put the pretreated carbon / carbon composite material into a graphite crucible, and embed it in the embedding powder;

[0052] 2) ...

Embodiment 3

[0064] Step 1: C / C composite material pretreatment:

[0065] 1) Take the 2D-carbon / carbon composite material used for aircraft brake pads and process it into 40×40×40mm 3 The cube, and its surface treatment of grinding and chamfering, the chamfering is 40°;

[0066] 2) Then use deionized water and absolute ethanol to ultrasonically clean 5 times respectively, the ultrasonic time of each cleaning is 30min, the ultrasonic power is 120W, and finally dry in an electric blast drying oven at 60°C.

[0067] Step 2: Prepare SiC porous inner coating on the surface of C / C composite substrate by embedding method

[0068] 1) First, take commercially available analytically pure Si powder, C powder and B powder with a particle size of 20-30 μm 2 o 3 Powder, according to Si powder: C powder: B 2 o 3 Powder = 5:6:1.0 mass ratio to prepare embedding powder, then put the pretreated carbon / carbon composite material into a graphite crucible, and embed it in the embedding powder;

[0069] 2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com