Double-throttling three-differential-pressure wet-gas two-phase flow measurement system

A measurement system and double-throttling technology, which is applied in the direction of detecting fluid flow by measuring pressure difference, volume/mass flow generated by mechanical effects, etc., can solve the problem of low signal-to-noise ratio of measurement signal, low measurement accuracy and wide measurement range and other problems, to achieve the effect of high signal-to-noise ratio of measurement signal, good weight balance, and improved measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below with reference to the accompanying drawings and relevant experimental data.

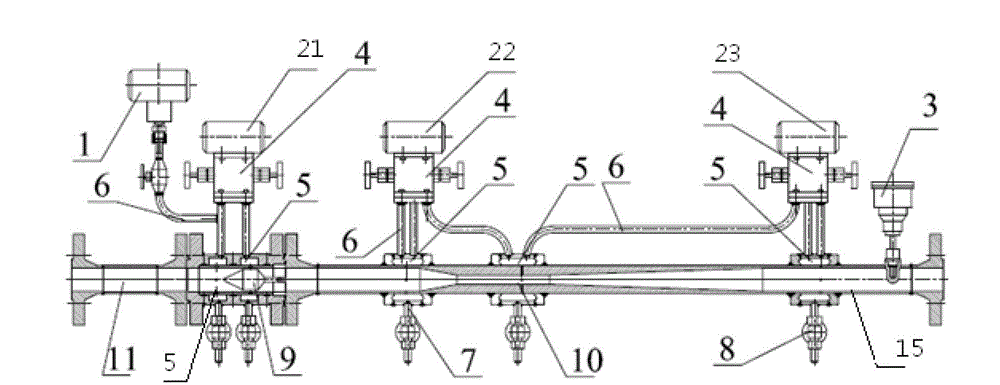

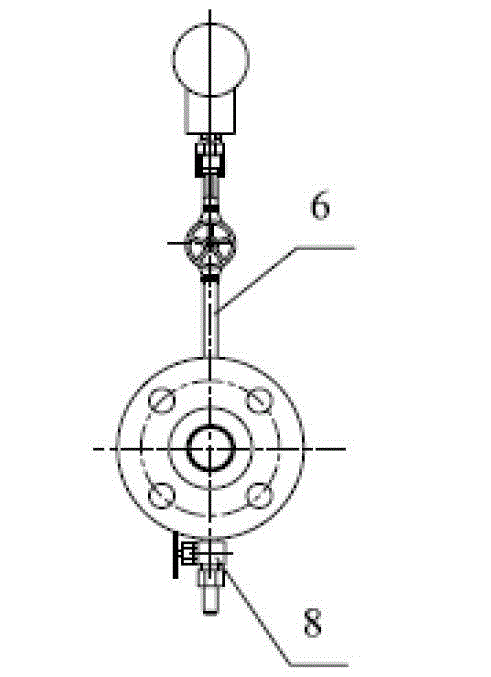

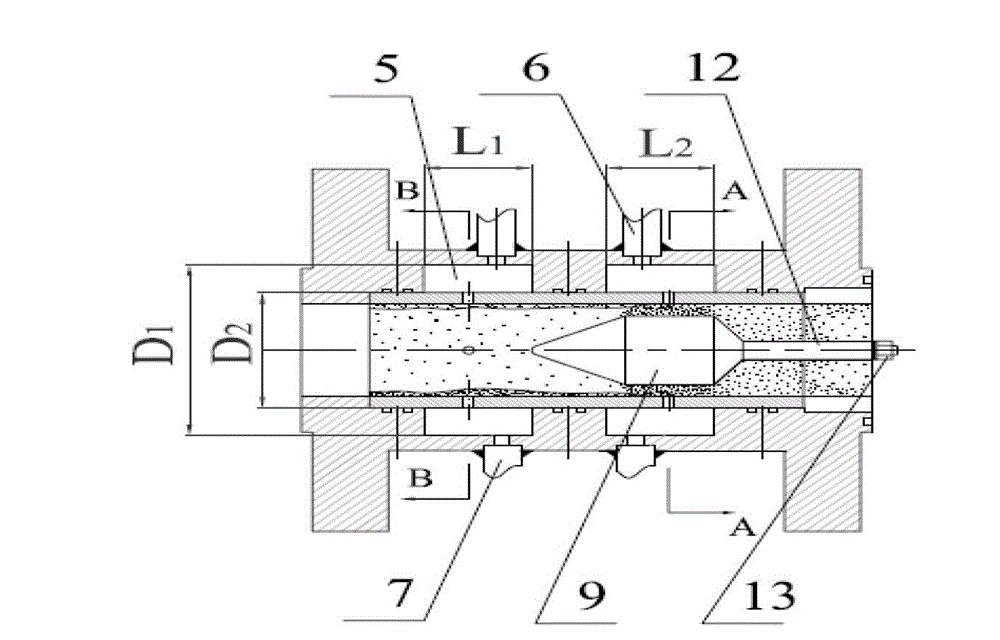

[0019] The system diagram of the present invention is shown in Figure 1, including the first throttling device at the front end, that is, the conical throttling device at the throat with long shrinkage of the fluid side wall, and the second throttling device at the rear end, that is, the long throat Venturi throttling device devices, such as figure 2 ,image 3. The device of the present invention differs from the previous wet gas flow measurement device in that the two throttling devices can provide three-stage differential pressure signals, and the two throttling devices have a more optimized structure and pressure measurement method, which can realize the measurement Effective improvement of range and measurement accuracy, while ensuring its reliability, safety and work efficiency.

[0020] The first throttling device is a coni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com