Aluminum-doped zinc oxide (AZO) transparent conducting film and preparation method thereof

A transparent conductive film, aluminum-doped zinc oxide technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve problems such as being unsuitable for large-area production, unfavorable for flexible substrate coating, power consumption, etc. Achieve the effect of increasing anti-peeling ability, low cost and low resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

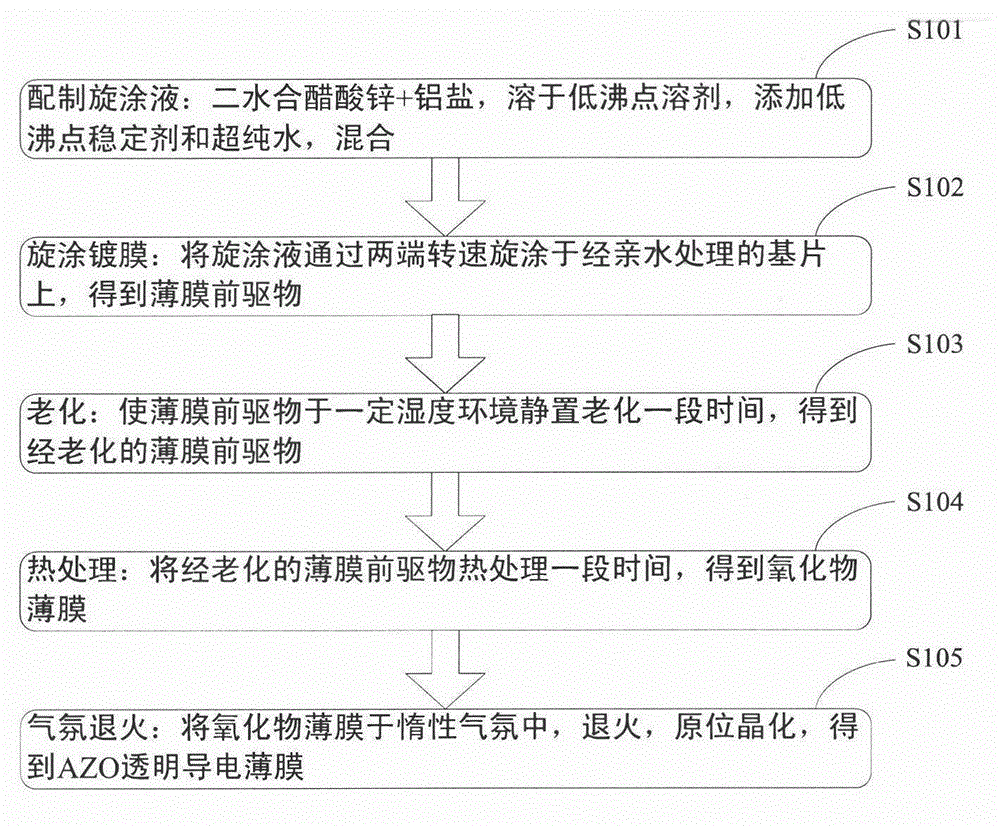

Method used

Image

Examples

Embodiment 1

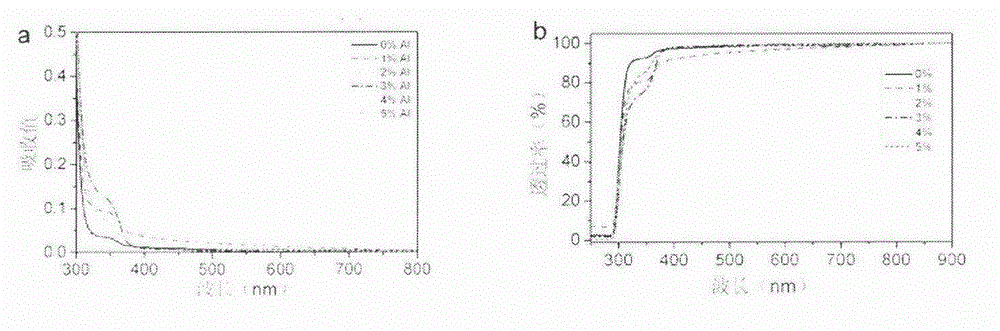

[0060] Weigh 0.8g of zinc acetate dihydrate and 0.0137g of aluminum nitrate nonahydrate, add 18ml of ethanol, stir, then add 6ml of water and 0.6ml of glacial acetic acid to form a clear and transparent solution. [Al / Zn] is 1%,

[0061] Common soda-lime glass was used as the spin-coating substrate. Substrates are washed with detergent to remove visible stains from the surface; rinse with tap water. Then soak in a mixed solution of ultrapure water and ammonia water-hydrogen peroxide, and then ultrasonically clean; rinse with ultrapure water. Then soak and ultrasonically clean with ultrapure water, hydrochloric acid-hydrogen peroxide mixed solution; rinse with ultrapure water. Store in ethanol and air dry before use.

[0062] Coating using a spin coater. Add the liquid evenly and dropwise at rest. First, uniform the glue at 500rpm for 10 seconds, then at 1800rpm for 40 seconds, and repeat the spin coating 4 times.

[0063] The coated substrate was aged in a 60% RH environme...

Embodiment 2

[0068] Similar to Example 1, the only difference is that the amount of aluminum nitrate nonahydrate added is 0.0683g, and the heat treatment temperature is 200°C. [Al / Zn] is 5%.

Embodiment 3

[0070] Similar to Example 1, the only difference is that the amount of aluminum nitrate nonahydrate added is 0.0683g, and the stabilizer is 0.4ml formic acid. [Al / Zn] is 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com