Strain for nattokinase with high activity and thermal stability and fermented product thereof

A fermented product, the technology of nattokinase, which is applied in the field of microorganisms, can solve the problems of nattokinase’s thermal instability, and achieve the effects of good quality natto, improved dissolution activity, and high fibrin hydrolysis activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1 Screening of highly active thermostability mutant strain BSNK-T160

[0042] 1. Materials

[0043] 1.1 Strains

[0044] BSNK-5, Bacillus subtilis natto isolated, screened and identified from Chinese black soybean Douchi by the inventor's laboratory.

[0045] 1.2 Medium

[0046] Seed and liquid fermentation medium: LB medium;

[0047] Screening medium: casein plate medium.

[0048] 1.3 Vitality assay method

[0049] Casein plate method: put the plate (9cm×9cm) on a level to adjust the level, prepare 1% agarose with 10mM pH7.2 PBS solution, heat it in a microwave oven to melt it, add an equal volume of casein prepared by pH8.9 Tris-HCl buffer Protein solution, so that the final concentration is 3mg / ml, pour it into the plate while it is hot, drive the air bubbles to the edge, and solidify at room temperature. Use a puncher with a diameter of 5mm to punch a hole, put the sample to be tested into the hole, incubate at 37°C for 18 hours, take out the plate car...

Embodiment 2B

[0062] Embodiment 2 BSNK-T160 Fibrin Hydrolysis Activity Determination

[0063] 1. Vitality determination method

[0064] Preparation of agarose-fibrin plates

[0065] pH 7.2 PBS solution containing 1% agarose, in a constant temperature water bath at 50°C for 45 minutes, add thrombin (final activity 0.05 IU / ml) and an equal volume of pH 7.2 PBS solution containing 0.1% fibrinogen in water bath at the same temperature for 10 minutes, mix uniform. Add 35ml of this solution to a 9cm×9cm petri dish, and after solidification, punch a hole with a 5mm diameter puncher, load 10ul of the sample, and incubate at a constant temperature at 37°C for 18h, measure the diameter of the dissolution circle, calculate the area of the dissolution circle, and calculate according to the standard curve of urokinase Enzyme activity unit.

[0066] Method for making standard curve of urokinase

[0067] Spot 10ul of each urokinase sample (100, 200, 300, 400, 500U / m1) on a freshly prepared fibrin pl...

Embodiment 3

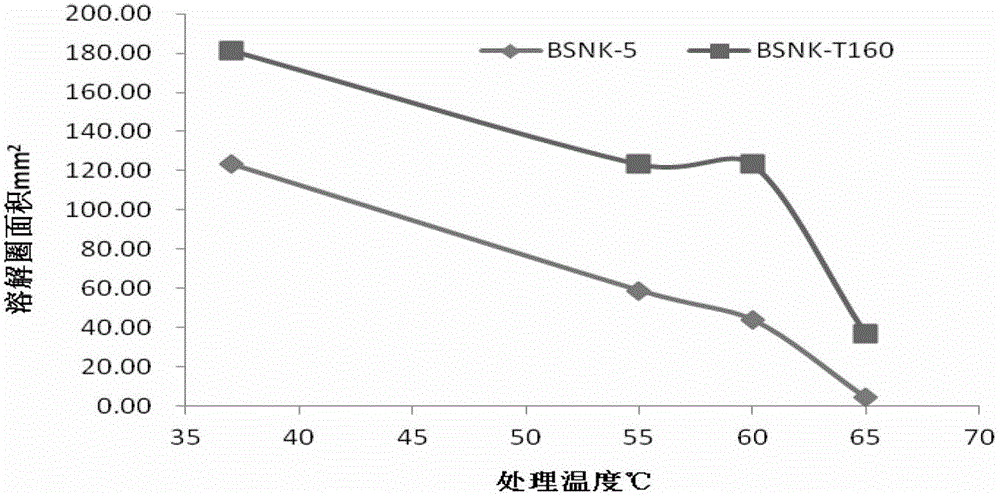

[0073] After heat treatment at 65°C, the area of the dissolution zone of BSNK-5 was 93.42mm2, and the activity relative to urokinase was 77IU / ml; the area of the dissolution zone of BSNK-T160 was 123.44mm2, and the activity relative to urokinase was 140.38IU / ml; Compared with BSNK-5, the area of BSNK-T160 dissolution circle increased by 32.13%, and the activity of urokinase increased by 82.31% ( Figure 4 ). Embodiment 3BSNK-T160 fermentation produces natto

[0074] 1. Process flow

[0075] Soybean raw material-cleaning-soaking-cooking-inoculation-fermentation-cooking-natto; take BSNK-T160 strain and make natto trial according to the above process.

[0076] 2. Method

[0077] 2.1 Bacterial suspension preparation

[0078] Inoculate the BSNK-T160 strain from the LB plate into 3ml liquid medium, incubate at 37°C for 8-9h, add 2% of the inoculum into 20ml LB liquid medium, incubate at 37°C for 4-6h, collect the bacteria by centrifugation, normal saline or without The ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com