Conductive composite with positive temperature coefficient (PTC), preparation method and application thereof

A conductive composite material, positive temperature coefficient technology, applied in resistors with positive temperature coefficient, resistors with current response, etc., can solve the problems of poor adhesion, can not effectively reduce the overall resistance value, poor resistance reproducibility, etc. Adhesion, saving labor cost and raw material cost, effect of reducing resistance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

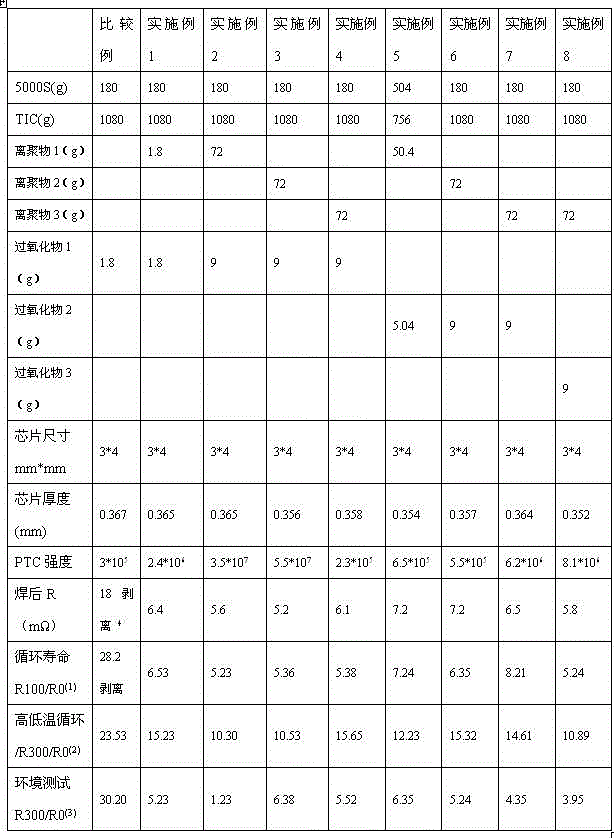

[0049] Set the feed temperature of the batch mixer (Hakke-600) at 170°C, the feed program is to add a certain amount of high-density polyethylene 180G and ionomer 1 to 1.8g, and then add titanium carbide after stirring for 1 minute 1080, the mixing speed is set at 15rmp. After 2 minutes, immediately increase the speed to 60rmp. After continuing to knead for 5 minutes, the material was discharged to form a conductive composite material with a positive temperature coefficient.

[0050] The above composite material is then plasticized on an open mill, and peroxide 1 is added, with a mass of 1.8g, and drawn into a sheet of 10cm*20cm. Put a layer of Teflon release cloth on the top and bottom of the above materials, heat it for 2 minutes first, and pre-press the operating pressure at 10Kg / cm 2 , the temperature is 180°C, and the exhaust and pressurization are performed once. Press again, the time is 10 minutes, and the pressing pressure is controlled at 150kg / cm 2 , the temperatur...

Embodiment 2

[0052] The procedure for preparing the positive temperature coefficient element is the same as that of Example 1, except that the ionomer 1 is changed to 72 g, and the electrical properties of the positive temperature coefficient element are shown in Table 2.

Embodiment 3

[0054] The steps for preparing the positive temperature coefficient element are the same as in Example 2, except that ionomer 1 is replaced by ionomer 2, the mass is 72 g, and the electrical properties of the positive temperature coefficient element are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com