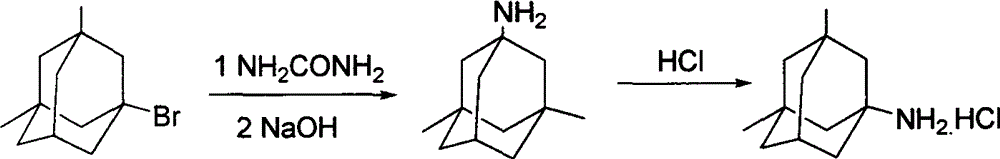

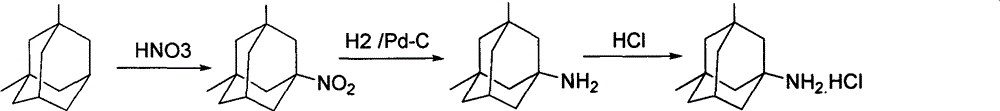

Synthesis of memantine hydrochloride

A technology of memantine hydrochloride and concentrated hydrochloric acid, which is applied in the field of memantine hydrochloride, can solve the problems of long reaction time, complicated post-treatment, severe heat release, etc., and achieve the effects of low production cost, shortened reaction time, and lowered reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] First, buy 1-chloro-3,5-dimethyladamantane on the market (require its GC≥98%. The appearance is colorless or light yellow liquid) or use self-made 1-chloro-3,5-dimethyl Adantane; the applicant uses self-made 1-chloro-3,5-dimethyladamantane, and its self-made method is as follows:

[0041] Preparation of 1-Hydroxy-3,5-Dimethyladamantane

[0042] Take 250g (1.52mol) of 1,3-dimethyladamantane in a three-necked flask, connect the drying pipe and exhaust gas absorption device, add 390mL (7.31mol) of bromine water dropwise at room temperature (the dropwise addition is completed in about 10-15 minutes), drop After completion, the mixture was heated to 90°C and refluxed for 5 h, cooled to room temperature, extracted by adding 100 mL of ether, washed with 4 L of 15% sodium bisulfite, separated the organic layer, dried over anhydrous sodium sulfate, concentrated to obtain a white solid, washed with petroleum ether , and dried to give 1-hydroxy-3,5-dimethyladamantane (260 g) in p...

Embodiment 2

[0048] Mix (10g, 0.05mol) 1-chloro-3,5-dimethyladamantane and (51mL, 1.30mol) formamide, heat to 150°C for 8 hours, cool to room temperature, add 30ml of ice water at 0°C , 70 mL of chloroform, extracted, separated the organic phase, and dried over anhydrous sodium sulfate. Concentration gave a white solid, which was dried under vacuum at 35°C to give 1-carboxamido-3,5-dimethyladamantane (9.9 g). Yield 95%, purity (99.7% GC). Continue to add it to 80mL concentrated hydrochloric acid, heat to reflux at 100°C for 7h, cool the reaction solution, stir at room temperature for 2h, a white solid is produced, filter with suction, and dry under vacuum at 50°C to obtain memantine hydrochloride (8.3g) with purity (99.8% GC) The total yield is 76.5%.

[0049] The difference from Example 1 is that the amount of aminating agent formamide changes, but basically does not affect the product purity and yield.

Embodiment 3

[0051] Mix (20g, 0.10mol) 1-chloro-3,5-dimethyladamantane and formamide (100mL, 2.50mol), heat and react at 150°C for 8 hours, then add 70ml of ice water at 0°C, chloroform 100 mL was extracted, the organic phase was separated, dried over anhydrous sodium sulfate, concentrated to obtain a white solid, and dried under vacuum at 35°C to obtain 1-formamido-3,5-dimethyladamantane (20.2 g). Yield 97.1%, purity (98.9% GC). Add it to 190mL concentrated hydrochloric acid, heat to 100°C and reflux for 7h, cool the reaction solution, stir at room temperature for 2h, a white solid is produced, filter it with suction, and dry it under vacuum at 50°C to obtain memantine hydrochloride (16.8g) with purity (99.85% GC) , a total yield of 77.6%.

[0052] The difference from Example 1 is that the amination reaction conditions remain unchanged, and the hydrolysis of 1-formyl 3,5-dimethyladamantane with concentrated hydrochloric acid becomes 10 times the specific product yield and purity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com