Halogen-free flame retardant heat conduction insulation warmish and preparation method thereof

A thermal insulation, insulating paint technology, applied in polyester coatings, coatings, etc., can solve the problems of halogen-free flame retardant, poor thermal conductivity, high temperature loss and other problems, achieve thermal conductivity flame retardant, high thermal conductivity, fast curing speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

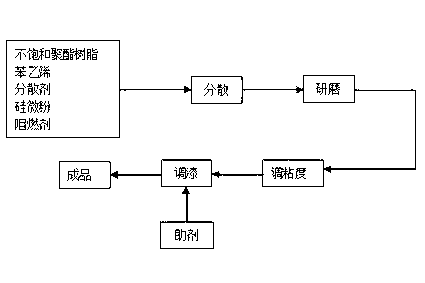

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 (by weight percentage):

[0031] Heat-resistant unsaturated polyester resin: 45%

[0032] Styrene: 20%

[0033] Alumina: 20%

[0034] Magnesium hydroxide: 5%

[0035] DOPO: 10%

[0036] Hydroquinone: 0.05%

[0037] p-Benzoquinone: 0.03%

[0038] BYK 9076 2%

[0039] BYK 333: 0.2%

[0040] Defom 3100: 0.1%

[0041] Cobalt naphthenate: 0.05%

[0042] tert-butyl peroxybenzoate: 2%

Embodiment 2

[0043] Embodiment 2 (by weight percentage):

[0044] Heat-resistant unsaturated polyester resin: 34%

[0045] Vinyltoluene: 23%

[0046] Silica powder: 18%

[0047] Aluminum hydroxide: 18%

[0048] Triphenyl phosphate: 7%

[0049] Hydroquinone: 0.05%

[0050] o-Toluene Hydroquinone: 0.03%

[0051] BYK 220S: 2%

[0052] TEGO Flow 370: 0.2%

[0053] BYK065: 0.1%

[0054] Cobalt isooctanoate: 0.05%

[0055] Di-tert-butylperoxycyclohexane: 2%

Embodiment 3

[0056] Embodiment 3 (by weight percentage):

[0057] Heat-resistant unsaturated polyester resin: 30%

[0058] Diallyl phthalate: 20%

[0060] Magnesium hydroxide: 20%

[0061] Hydroquinone: 0.08%

[0062] Disponer 931 2%

[0063] BYK 315: 0.2%

[0064] TEGO Rad 2500: 0.1%

[0065] Manganese naphthenate: 0.08%

[0066] Di-tert-butyl peroxide: 2%

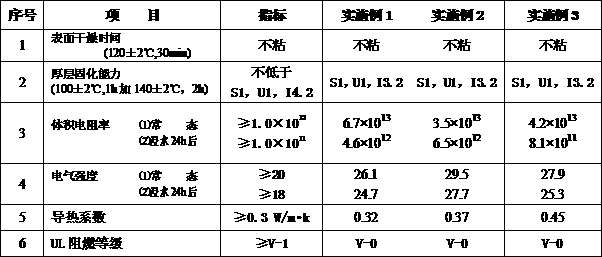

[0067] Example effect

[0068] After the above flame-retardant and heat-conducting insulating varnish is cured by heating, its properties are shown in Table 1:

[0069] Table 1. Properties of flame retardant and thermally conductive insulating varnishes

[0070]

[0071] The tests of various indicators are carried out according to the provisions of GB / T 15023-1994 "Test Methods for Electrical Insulation Solvent-free Polymerizable Resin Compounds".

[0072] Volume resistivity, electric strength, thermal conductivity and flame retardant grade: The sample curing condition is 120±2°C, 0.5h plus 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com