A method of manufacturing an LED package

A LED packaging body and LED packaging technology, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of large amount of phosphor powder and uneven coating of phosphor powder, and achieve the effect of flexible and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

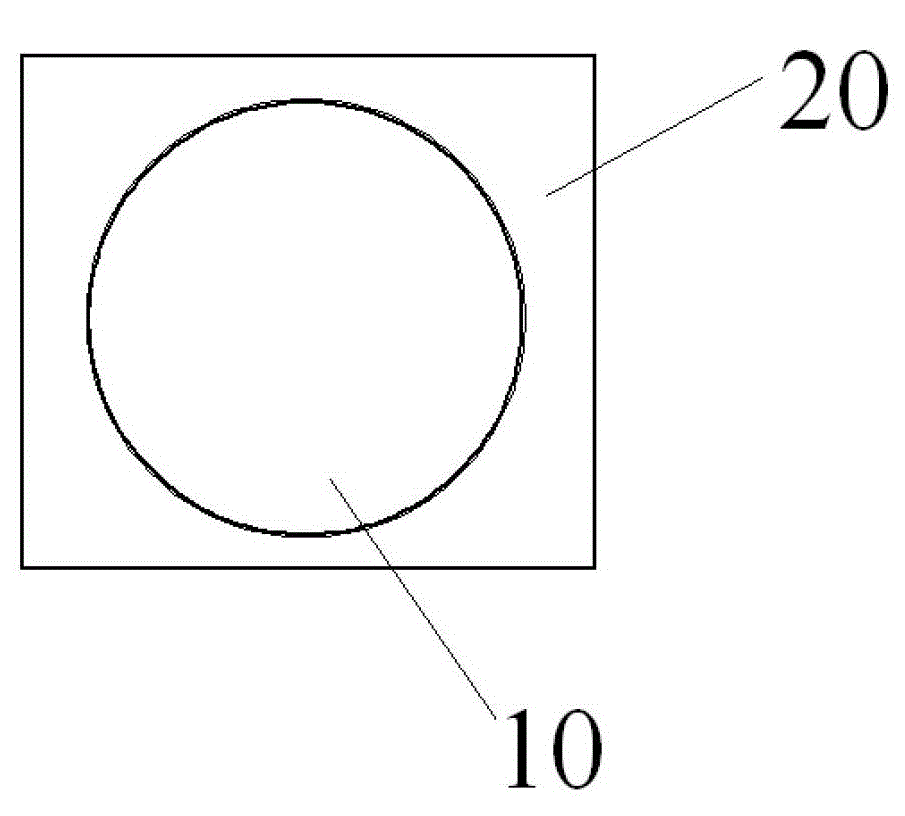

[0032] 1) if figure 1 As shown, the LED wafer 10 is fixed on the adhesive film 20 (the electrode pins are stuck on the adhesive film, figure 1 not shown in );

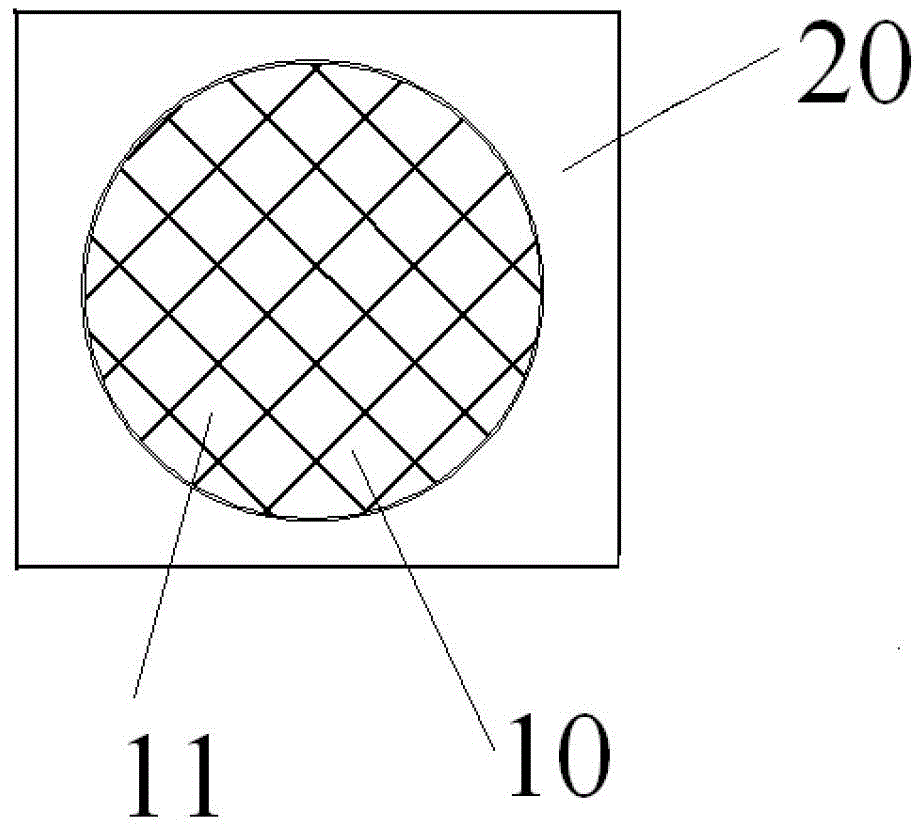

[0033] 2) Carry out cutting to obtain LED chips 11 of suitable size, such as figure 2 shown;

[0034] 3) Spray, brush, roll or screen-print phosphor glue, or press thermoplastic curing glue to apply phosphor-containing glue to the above-mentioned entire board of LED chips 11 on the adhesive film, and bake Curing to obtain a whole board of LED chips 11 uniformly coated with phosphor powder, such as image 3 shown;

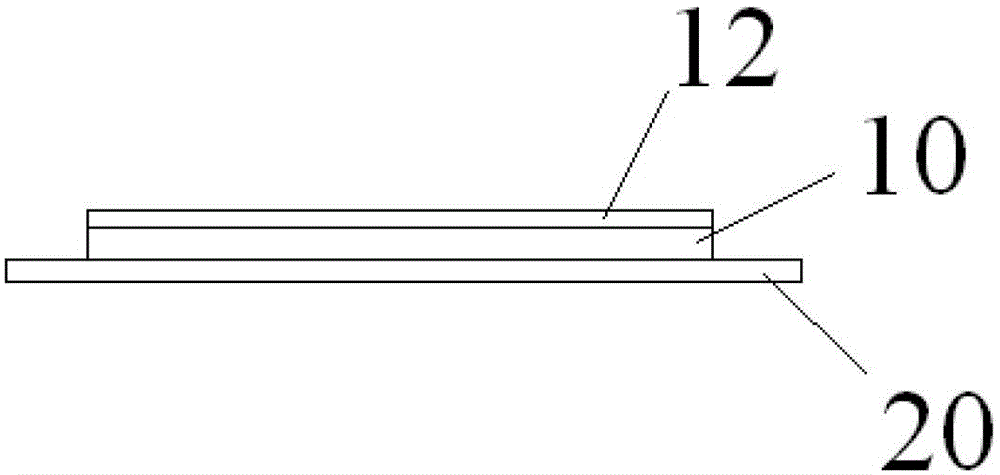

[0035] 4) Carry out crystal expansion treatment on the entire board LED chip 11 evenly coated with phosphor powder on the adhesive film, such as Figure 4 As shown, the LED chip 11 provided with the phosphor layer 12 is obtained;

[0036] 5) Encapsulate the LED chip 11 provided with the phosphor layer 12; wherein, the encapsulation may include the following steps: cleaning the encapsulation substrate,...

Embodiment 2

[0038] 1) if figure 1As shown, the LED wafer 10 is fixed on the adhesive film 20 (the electrode pins are stuck on the adhesive film, figure 1 not shown in ),

[0039] 2) Carry out cutting to obtain LED chips 11 of suitable size, such as figure 2 shown;

[0040] 3) Carry out crystal expansion treatment on the entire board of LED chips 11 on the adhesive film, such as Figure 4 shown;

[0041] 4) Apply phosphor-containing glue to the entire LED chip 11 on the adhesive film by spraying, brushing, rolling or screen-printing phosphor glue, or pressing thermoplastic curing glue, and bake Curing to obtain the whole board LED chip 11 uniformly coated with phosphor layer 12, such as image 3 Shown; The LED chip 11 that obtains after cutting is as Figure 5 As shown, wherein the fluorescent layer 12 covers the surface of the LED chip 11;

[0042] 5) Encapsulate the LED chip 11 provided with the phosphor layer 12; wherein, the encapsulation may include the following steps: cleani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com