Poly(vinyl imidazole-acrylate-acrylic acid)polyethylene glycol quasi solid electrolyte and preparation method and application thereof

A vinyl imidazole and acrylate technology, applied in the field of poly/polyethylene glycol quasi-solid electrolyte and its preparation, can solve the problems of DSSC battery packaging difficulties, corrosion of counter electrodes, short life, dye desorption, etc., and achieve electrochemical Good stability, improved electrical conductivity, and easy packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

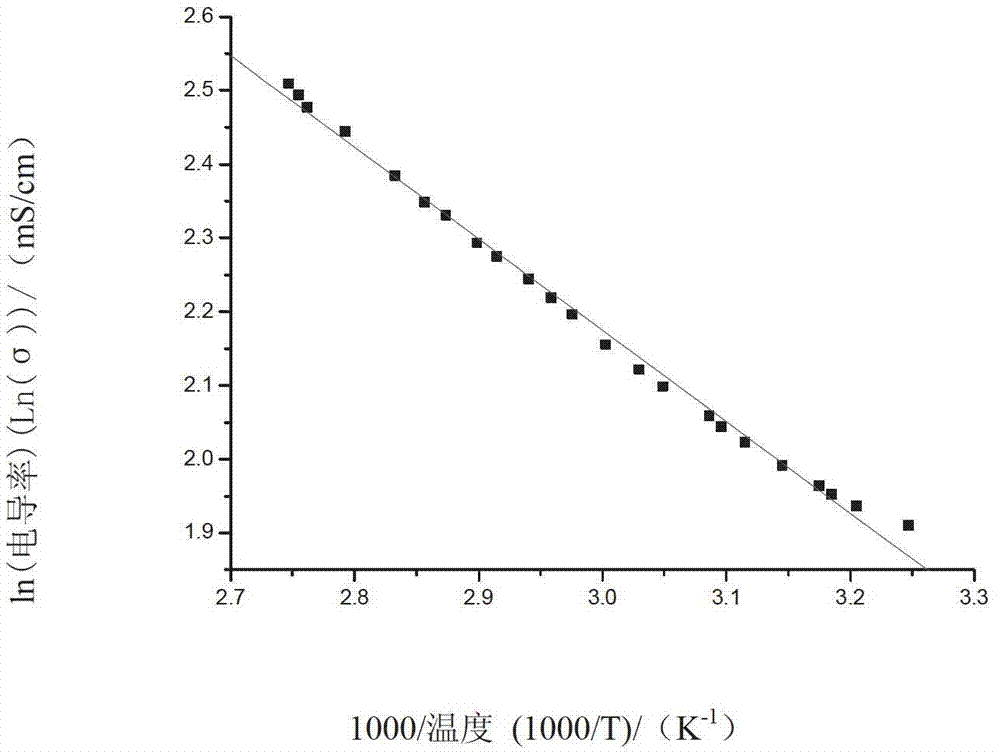

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of poly(vinylimidazole-acrylate-acrylic acid) / polyethylene glycol P(VIM-A-AA) / PEG blend gel electrolyte is through P(VIM-A-AA) / PEG blending And redox p-iodide / I 2 The mixing reaction forms the quasi-solid electrolyte of the present invention. Specifically, the preparation method of the present invention includes the following steps:

[0042] Step 1: Preparation of poly(vinylimidazole-acrylate-acrylic acid) / polyethylene glycol blend

[0043] The reaction flask is respectively connected with condensed water and flowing nitrogen. First, polyethylene glycol and solvent are added to the reaction flask, and the vinyl imidazole monomer and acrylic ester monomers such as methyl methacrylate (MMA), methyl acrylate and butyl acrylate are added. Ester (BA), hydroxyethyl methacrylate, hydroxypropyl acrylate, fluoroheptyl acrylate, fluoroheptyl methacrylate, acrylic monomers such as methacrylic acid (MAA) or acrylic acid are dissolved in a solvent; The initiator ...

Embodiment 1

[0065] Step 1: Preparation of poly(vinylimidazole-methyl methacrylate-methacrylic acid) / polyethylene glycol blend

[0066] The reaction flask was connected with condensed water and flowing nitrogen. Firstly, 3.00g polyethylene glycol (PEG400) and 3ml toluene were added to the reaction flask, 2.08g vinyl imidazole, 4.53g acrylic ester monomer methyl methacrylate, acrylic acid The monomer methacrylic acid 0.35g is dissolved in toluene 3ml; the initiator azobisisobutyronitrile 0.11g is dissolved in the solvent 1ml toluene, the flowing nitrogen is passed, the temperature is raised to 70℃, the vinyl imidazole monomer and acrylate monomer The solution and the initiator solvent were slowly dropped into the reaction flask at the same time, and reacted for 12 hours. In this embodiment, the solvent toluene can be replaced with chloroform, tetrahydrofuran, etc.

[0067] In this embodiment, the mass ratio of monomer vinylimidazole: methyl methacrylate: methacrylic acid: initiator azobisisobut...

Embodiment 2

[0085] Step 1: Preparation of poly(vinylimidazole-methyl methacrylate) / polyethylene glycol blend

[0086] In this example, the content of acrylic monomer is zero, so that the properties of the polymer electrolyte when the content of acrylic monomer is zero are investigated.

[0087] The reaction flask was connected with condensed water and flowing nitrogen. First, 6.3g polyethylene glycol (PEG20000) and 3ml chloroform were added to the reaction flask, and 0.3g vinyl imidazole and 2.4g methyl methacrylate, an acrylic monomer, were dissolved in the reaction flask. In 2ml of chloroform; dissolve 0.0286g of the initiator azobisisobutyronitrile in 1ml of chloroform, flow nitrogen, and increase the temperature to 65℃. Add vinylimidazole monomer, acrylate monomer solution and initiator solvent simultaneously and slowly dropwise In the reaction flask, react for 20 hours. In this embodiment, the solvent chloroform can be replaced with toluene, tetrahydrofuran, etc.

[0088] In this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com