Method for preparing three-dimensional block polylactic acid at high efficiency

A polylactic acid and three-dimensional technology, which is applied in the field of efficient preparation of three-dimensional block polylactic acid, can solve the problems of low production efficiency and achieve the effects of convenient operation, low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

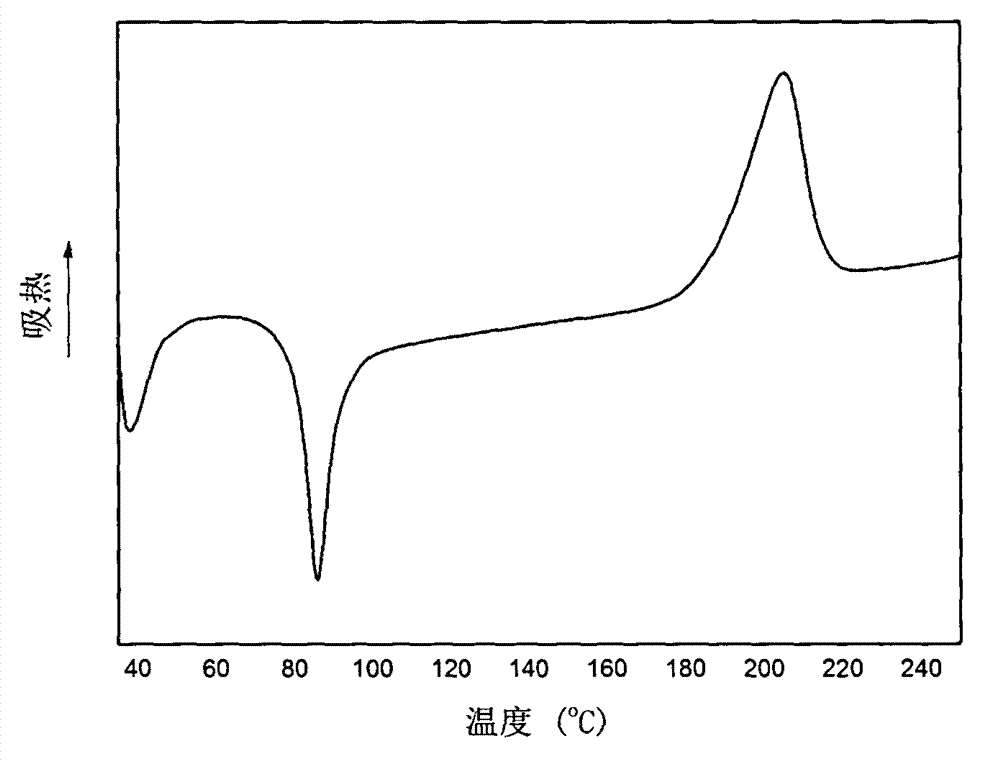

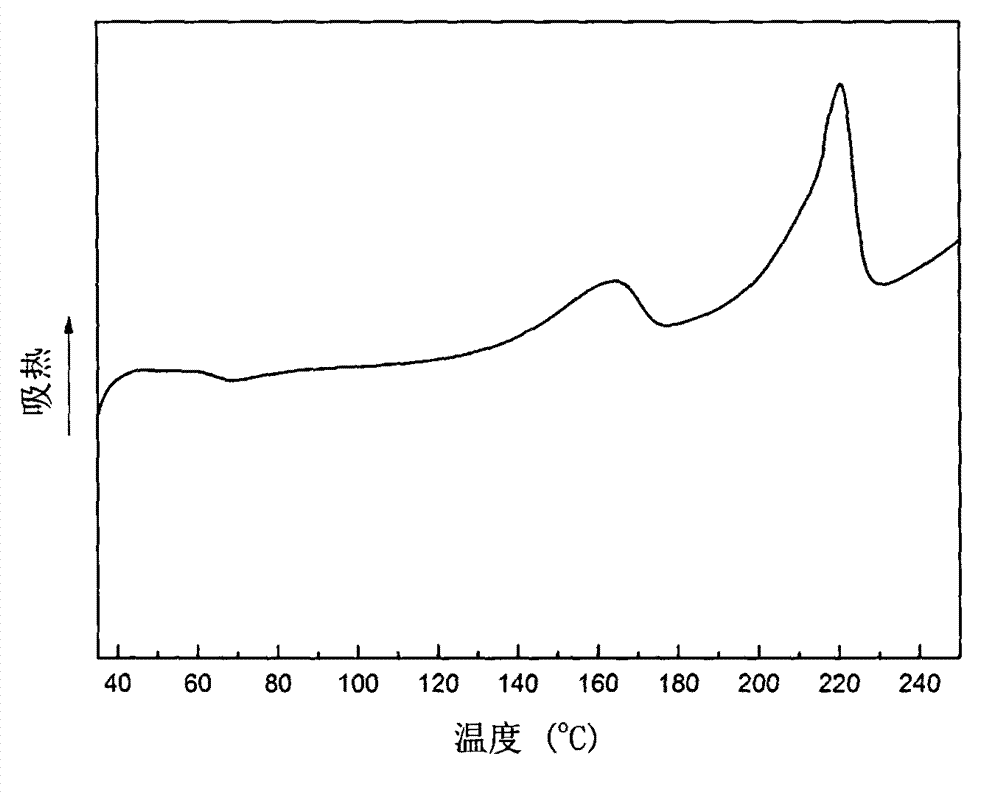

Image

Examples

preparation example 1

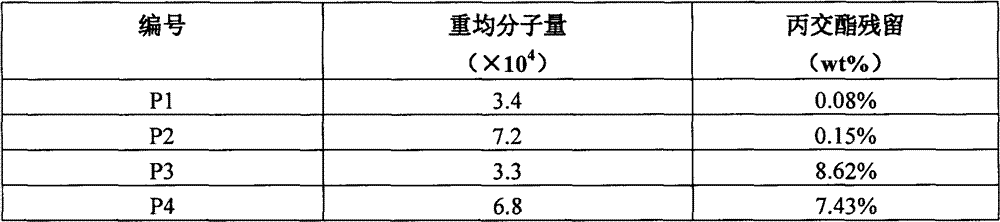

[0024] Add 20.0g of polymer grade D-type lactide, 0.004g of stannous octoate, and 0.18g of lauryl alcohol into the polymerization reactor. Under the protection of nitrogen, heat up to the first reaction temperature of 180°C, and react for 4 hours after reaching the set temperature. Then the temperature was lowered to the second reaction temperature of 130° C., and the reaction was performed for 2 hours to obtain the prepolymer P1.

preparation example 2

[0026] Add 20.0g of polymer grade D-type lactide, 0.004g of stannous octoate, and 0.10g of lauryl alcohol into the polymerization reactor. Under the protection of nitrogen, heat up to the first reaction temperature of 190°C, and react for 0h after reaching the set temperature. Then the temperature was lowered to the second reaction temperature of 100° C. and reacted for 5 hours to obtain prepolymer P2.

preparation example 3

[0028] Add 20.0g of polymer grade D-type lactide, 0.004g of stannous octoate, and 0.18g of lauryl alcohol into the polymerization reactor. Under the protection of nitrogen, heat up to the first reaction temperature of 180°C, and react for 0h after reaching the set temperature. Prepolymer P3 is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com