Guide cylinder and preparation method thereof

A technology of a guide tube and a production method, which is applied to chemical instruments and methods, self-melting liquid pulling method, crystal growth, etc., and can solve the problems that the guide tube cannot meet the production requirements, the graphite strength is low, and the heat preservation effect is poor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

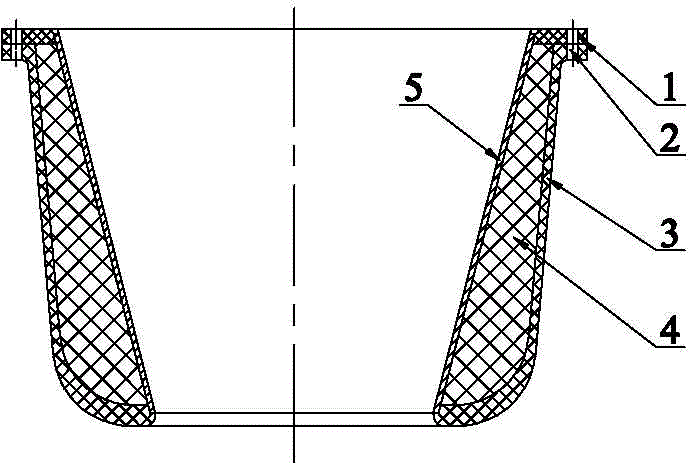

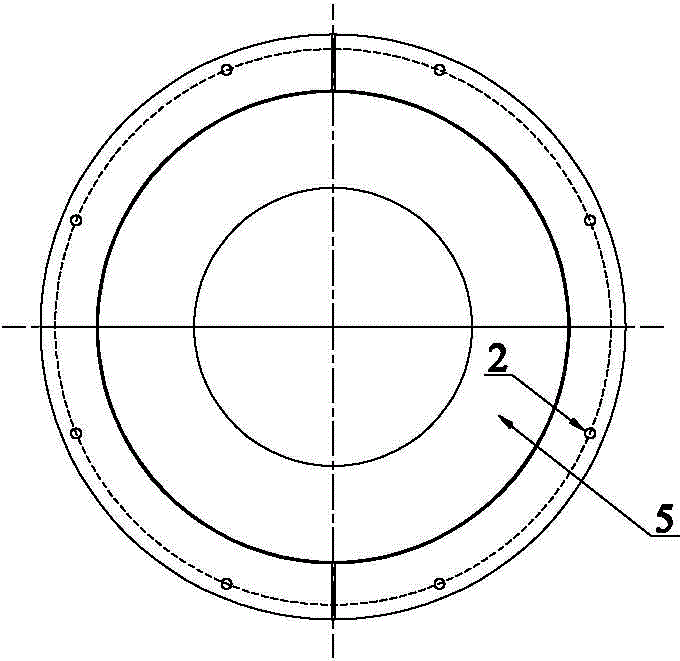

[0034] Depend on figure 1 , figure 2 It can be seen that a guide tube includes an inverted cone cylinder, and the cylinder includes an outer screen 3 and an inner screen 5, and an insulating layer 4 is provided between the outer screen 3 and the inner screen 5. The outer screen 3 is made of carbon / carbon composite material, and the inner screen 5 is made of metal molybdenum or metal tungsten (molybdenum metal is used in this embodiment); the outer screen 3 is connected with the outer screen 3 , the positioning disc 1 covered by the inner screen 5 and the insulation layer 4, so that the outer screen 3, the inner screen 5, the insulation layer 4 and the positioning disc 1 form an integral structure.

[0035] The thickness of the inner screen 5 according to the present invention is 0.5㎜~1.5㎜ (0.8㎜ in this embodiment); the positioning plate 1 is a multi-lobe structure (a two-lobe structure evenly divided in this embodiment), and graphite or Made of carbon / carbon composite mater...

Embodiment 2

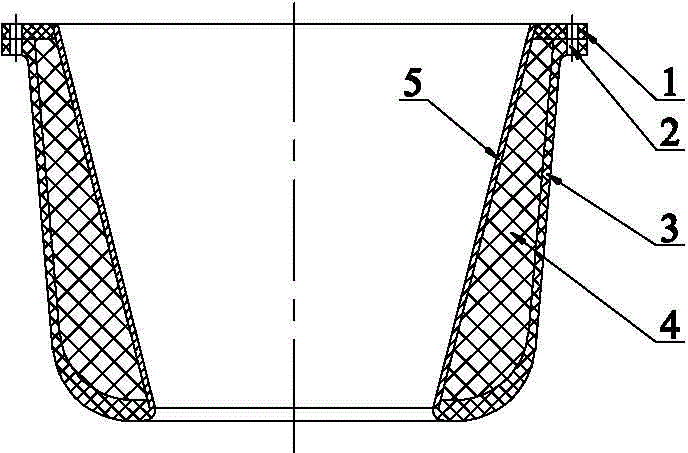

[0042] The positioning plate 1 of the present invention has a multi-lobed structure (this embodiment is a two-lobed structure), made of graphite, with a thickness of 5 mm to 15 mm (10 mm in this embodiment), and a density of 1.7 g / ㎝ 3 ~2.0g / ㎝ 3 (This embodiment is 1.8g / ㎝ 3 ).

[0043] A kind of preparation method of above-mentioned guide cylinder, it adopts density as 1.7g / ㎝ in step (1) in positioning disc 1 3 ~2.0g / ㎝ 3 (This embodiment is 1.8g / ㎝ 3 ) graphite material is machined according to the required size, and the thickness is 5 mm to 15 mm (10 mm in this embodiment); The positioning plate 1 is prepared by step (1) and connected with the outer screen 3 through fasteners, so that the positioning plate 1 covers the outer screen 3, the insulation layer 4, and the inner screen 5 to form a tight whole.

[0044] The rest are the same as embodiment 1.

Embodiment 3

[0046] The inner screen 5 of the present invention is made of metal molybdenum or metal tungsten (the metal tungsten used in this embodiment); the positioning plate 1 is made of graphite, with a thickness of 5mm-15mm (this embodiment 10㎜), the density is 1.7g / ㎝ 3 ~2.0g / ㎝ 3 (This embodiment is 1.8g / ㎝ 3 ); said insulation layer 4 has a density of 0.1g / ㎝ 3 ~0.5g / ㎝ 3 (0.25 g / ㎝ in this example 3 ) of cured felt or polyacrylonitrile-based carbon felt (this embodiment is cured felt).

[0047] Remaining with embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com