Preparation method for quasi-nanostructure WC-Co (tungsten-cobalt) coating with high compactness and low decarburization

A dense, quasi-nano technology, applied in the coating, metal material coating process, molten spraying, etc., can solve the problems of process route extension, fuel consumption increase, powder deposition efficiency reduction, etc., to achieve low decarbonization, improve Density, the effect of simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

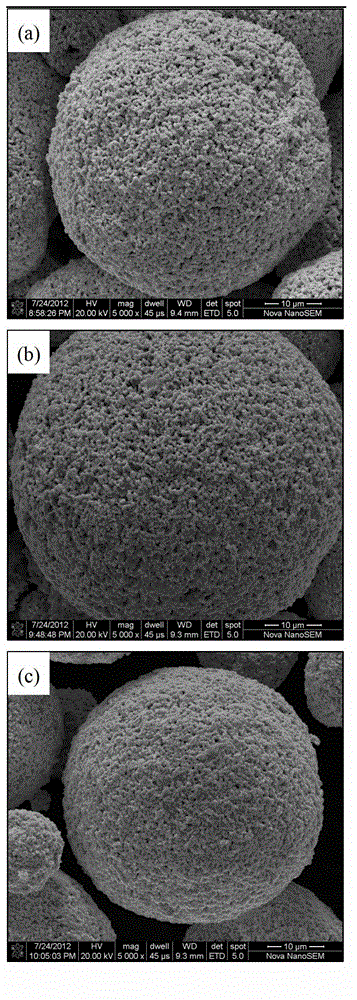

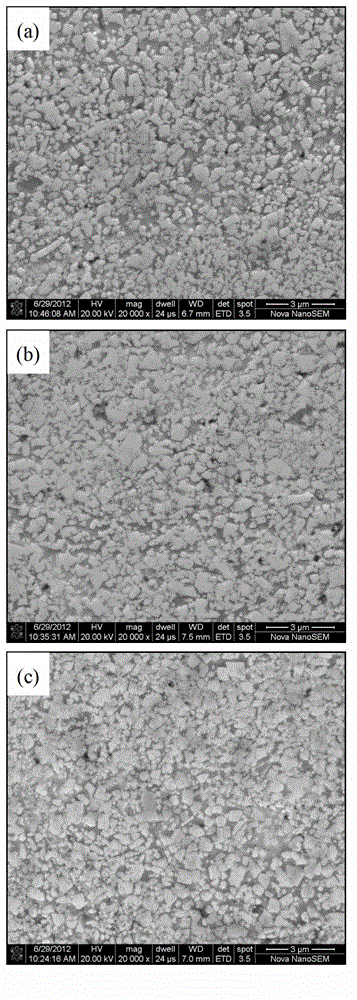

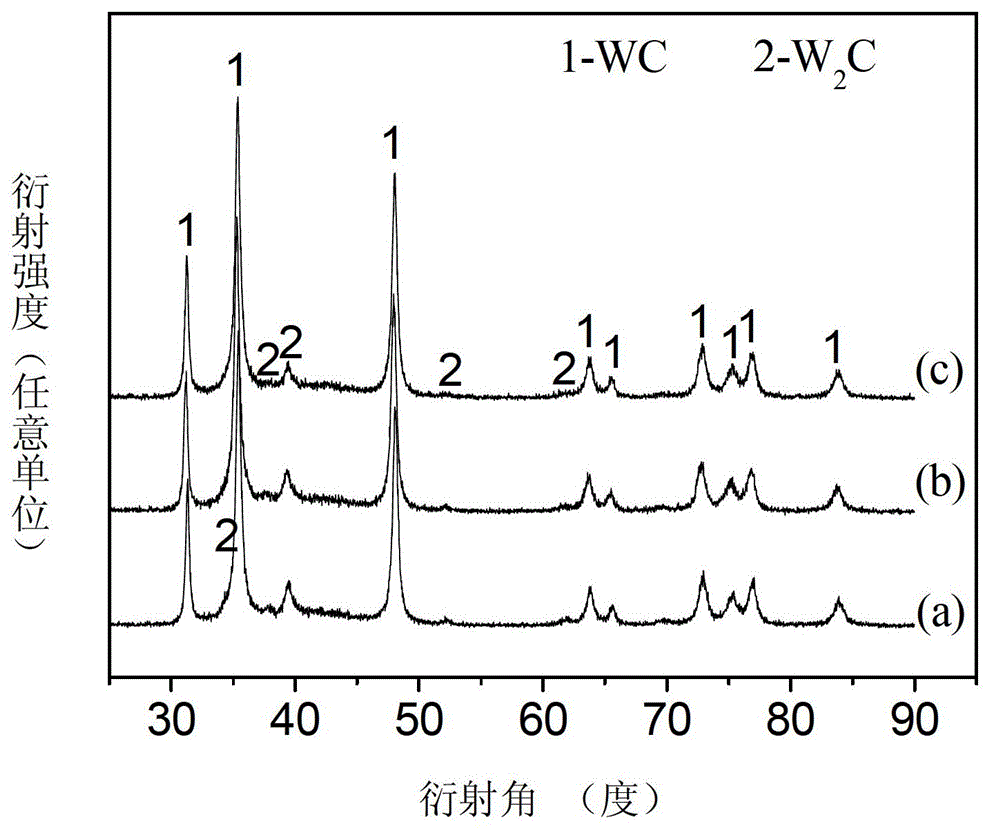

[0019] WC-12Co composite powder with an average particle size of 80nm and Cr with a mass fraction of 0.60% 3 C 2 The powder and VC powder with a mass fraction of 0.40% were mixed for ball milling, using absolute ethanol as the ball milling medium, and the ball milling time was 15 hours. After ball milling, it was dried in a vacuum oven at a temperature of 80°C for 15 hours. Then, the mixed powder after ball milling was spray-dried, granulated and heat-treated. First, it was raised from room temperature to 300°C at a heating rate of 3°C / min, and kept at 300°C for 1 hour; then it was raised to 800°C at a heating rate of 5°C / min. min, hold at 800°C for 1 hour; then raise to 1240°C with a heating rate of 7°C / min, and hold at 1240°C for 3 hours; then cool down to 400°C, control the cooling rate at 5°C / min, and finally cool to room temperature with the furnace, Keep the argon atmosphere in the furnace; for the granulated powder after heat treatment (such as figure 1 a) Sieve and c...

Embodiment 2

[0021] WC-12Co composite powder with an average particle size of 150nm and Cr with a mass fraction of 0.80% 3 C 2 The powder and VC powder with a mass fraction of 0.56% were mixed for ball milling, using absolute ethanol as the ball milling medium, and the ball milling time was 12 hours. After ball milling, it was dried in a vacuum oven at a temperature of 90°C for 12 hours. Then, the mixed powder after ball milling was spray-dried, granulated and heat-treated. First, it was raised from room temperature to 300°C at a heating rate of 3°C / min, and kept at 300°C for 1 hour; then it was raised to 800°C at a heating rate of 5°C / min. min, hold at 800°C for 1 hour; then raise to 1260°C with a heating rate of 7°C / min, and hold at 1260°C for 2 hours; then cool down to 400°C, control the cooling rate at 5°C / min, and finally cool to room temperature with the furnace, Keep the argon atmosphere in the furnace; for the granulated powder after heat treatment (such as figure 1 b) Sieve and ...

Embodiment 3

[0023] WC-12Co composite powder with an average particle size of 200nm and Cr with a mass fraction of 1.20% 3 C 2 The powder was mixed with VC powder with a mass fraction of 0.9% for ball milling, using absolute ethanol as the ball milling medium, and the ball milling time was 10 hours. After ball milling, it was dried in a vacuum oven at 100°C for 10 hours. Then, the mixed powder after ball milling was spray-dried, granulated and heat-treated. First, it was raised from room temperature to 300°C at a heating rate of 3°C / min, and kept at 300°C for 1 hour; then it was raised to 800°C at a heating rate of 5°C / min. min, hold at 800°C for 1 hour; then raise to 1280°C with a heating rate of 7°C / min, and hold at 1280°C for 1 hour; then cool down to 400°C, control the cooling rate at 5°C / min, and finally cool to room temperature with the furnace, Keep the argon atmosphere in the furnace; for the granulated powder after heat treatment (such as figure 1 c) Sieve and classify, and comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com