Titanium nickel aluminium molybdenum alloy material and preparation process thereof

A preparation process and molybdenum alloy technology, which is applied in the field of titanium-nickel-aluminum-molybdenum alloy material and its preparation process, can solve the problems of low mechanical properties of powder metallurgy materials, achieve the goal of improving strength, promoting alloy structure refinement, and promoting sintering densification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

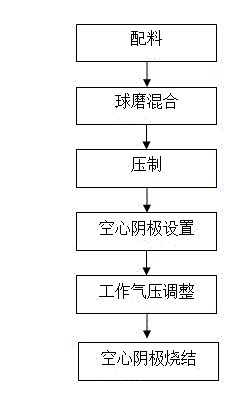

[0029] like figure 1 As shown, a kind of titanium-nickel-aluminum-molybdenum alloy material and its preparation process according to the present invention, the specific steps and its process conditions are as follows:

[0030] Step 1, batching: Take titanium powder with a particle size of 600 mesh, nickel powder with 1000 mesh, aluminum powder with 600 mesh, and nickel-molybdenum pre-alloyed powder with a molybdenum content of 20wt.% in 200 mesh for batching. The composition is calculated by atomic percentage, titanium 48.5% , Nickel 46.5%, Aluminum 4.5%, Molybdenum 0.5%.

[0031] Step 2, ball milling and mixing: put the above-mentioned powder into a ball mill tank at a ball-to-material ratio of 5:1, and ball mill it for 3 hours at a speed of 300r / min; ; Then pass the ball-milled mixture through the 100-mesh sieve specified in GB / T6005.

[0032] In step 3, the mixed material after ball milling and sieving in step 2 is subjected to two-way molding with a molding pressure of 4...

Embodiment 2

[0040] A kind of titanium-nickel-aluminum-molybdenum alloy material and its preparation process according to the present invention, concrete steps and process conditions thereof are as follows:

[0041] Step 1, batching: take titanium powder with a particle size of 800 mesh, nickel powder with 2000 mesh, aluminum powder with 800 mesh, nickel-molybdenum pre-alloyed powder with a molybdenum content of 20wt.% in 300 mesh for batching, and its composition is calculated by atomic percentage, titanium 47% , nickel 46%, aluminum 6.2%, molybdenum 0.8%.

[0042] Step 2, ball milling and mixing: put the above-mentioned powder into a ball mill tank at a ball-to-material ratio of 5:1, and ball mill for 4 hours at a speed of 250r / min; ; Then pass the ball-milled mixture through the 100-mesh sieve specified in GB / T6005.

[0043] In step 3, the mixed material after ball milling and sieving in step 2 is subjected to two-way molding with a molding pressure of 300 MPa to obtain a pressed blank...

Embodiment 3

[0049] A kind of titanium-nickel-aluminum-molybdenum alloy material and its preparation process according to the present invention, concrete steps and process conditions thereof are as follows:

[0050] Step 1, batching: take titanium powder with a particle size of 1000 mesh, nickel powder with 1500 mesh, aluminum powder with 1000 mesh, nickel-molybdenum pre-alloyed powder with a molybdenum content of 20wt.% in 400 mesh for batching, and its composition is calculated by atomic percentage, titanium 48% , Nickel 45%, Aluminum 6%, Molybdenum 1%.

[0051] Step 2, ball milling and mixing: put the above-mentioned powder into a ball mill tank at a ball-to-material ratio of 5:1, and ball mill it for 5 hours at a speed of 200r / min; ; Then pass the ball-milled mixture through the 100-mesh sieve specified in GB / T6005.

[0052] In step 3, the mixed material after ball milling and sieving in step 2 is subjected to two-way molding with a molding pressure of 500 MPa to obtain a compact.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com