Organic-inorganic composite hydrophilic coating

An inorganic composite and hydrophilic technology, applied in the direction of coating, etc., can solve the problems of poor stain resistance of exterior wall coatings, and achieve the effects of durable stain resistance, improved film-forming properties, and improved hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

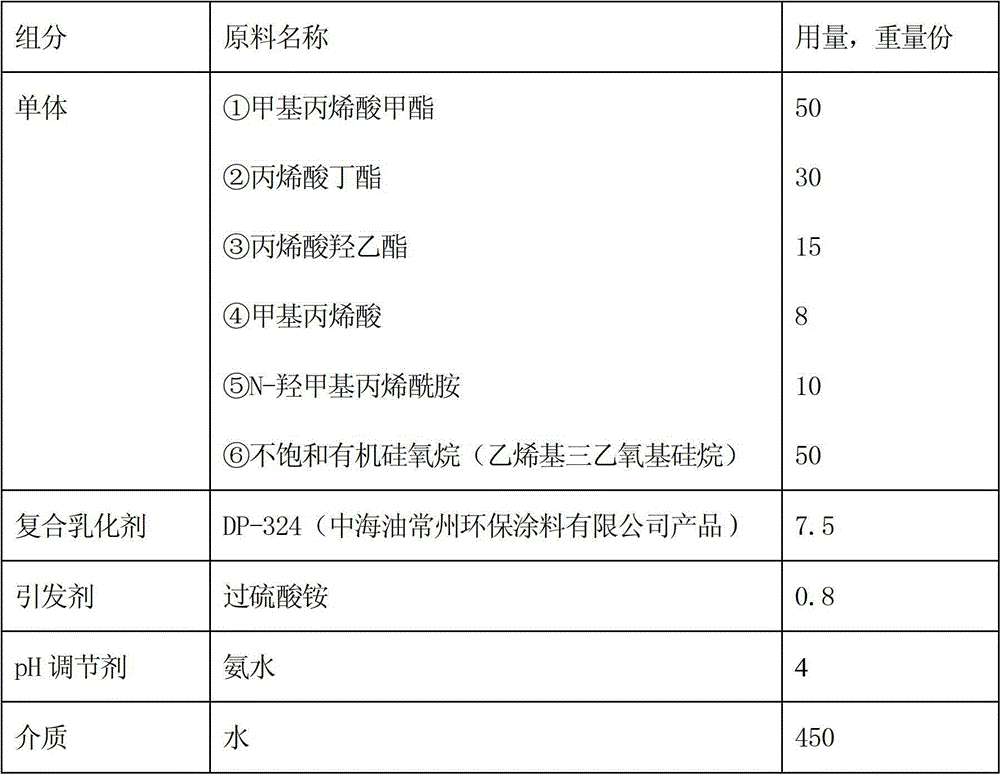

Embodiment 1

[0022] Prepare according to the following steps:

[0023] ① Prepare the raw materials according to the dosage in Table 1;

[0024] Table 1

[0025]

[0026] ②Add part of 160 parts by weight of water, 0.5 parts by weight of 11% compound emulsifier and 0.1 parts by weight of 20% ammonium persulfate into a reaction vessel equipped with a stirrer, thermometer, condenser and two dropping funnels, Methyl methacrylate monomer, butyl acrylate monomer, hydroxyethyl acrylate monomer, methacrylic acid monomer and unsaturated organosiloxane monomer are mixed uniformly, and then put into a dropping funnel, and the remaining Mix water, compound emulsifier and ammonium persulfate with all N-methylol acrylamide monomers uniformly, and then put them into another dropping funnel;

[0027] ③Start stirring and increase the temperature. When the temperature rises to 80°C, the materials in the 2 dropping funnels are added dropwise at the same time. After the dropwise addition is completed within 1.5 hours...

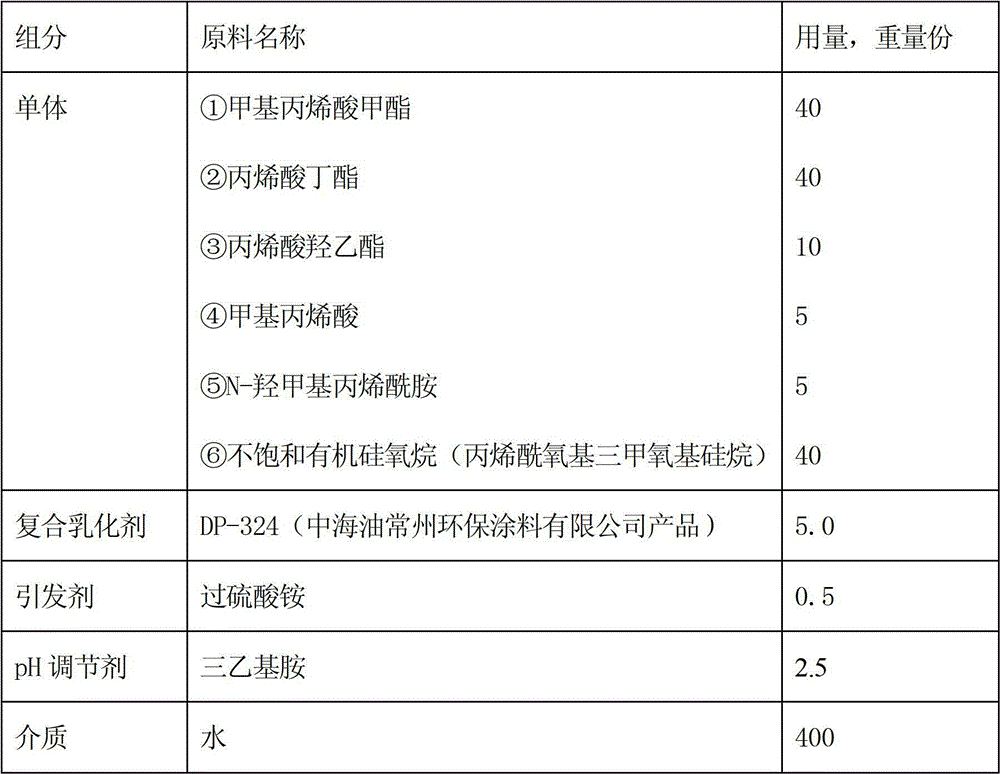

Embodiment 2

[0029] Prepare according to the following steps:

[0030] ① Prepare the raw materials according to the dosage in Table 2;

[0031] Table 2

[0032]

[0033] ②Add 250 parts by weight of part of water, 1.5 parts by weight of 20% composite emulsifier and 0.2 parts by weight of 25% ammonium persulfate into a reaction vessel equipped with a stirrer, thermometer, condenser and two dropping funnels, Methyl methacrylate monomer, butyl acrylate monomer, hydroxyethyl acrylate monomer, methacrylic acid monomer and unsaturated organosiloxane monomer are mixed uniformly, and then put into a dropping funnel, and the remaining Mix water, compound emulsifier and ammonium persulfate with all N-methylol acrylamide monomers uniformly, and then put them into another dropping funnel;

[0034] ③Start stirring and increase the temperature. When the temperature rises to 80°C, the materials in the two dropping funnels are added dropwise at the same time. After the dropwise addition is completed within 2 hour...

Embodiment 3

[0036] Prepare according to the following steps:

[0037] ① Prepare the raw materials according to the dosage in Table 3;

[0038] table 3

[0039]

[0040] ②Add 200 parts by weight of partial water, 1.0 part by weight of 20% composite emulsifier and 0.2 part by weight of 40% ammonium persulfate into a reaction vessel equipped with a stirrer, a thermometer, a condenser and two dropping funnels. Methyl methacrylate monomer, butyl acrylate monomer, hydroxyethyl acrylate monomer, methacrylic acid monomer and unsaturated organosiloxane monomer are mixed uniformly, and then put into a dropping funnel, and the remaining Mix water, compound emulsifier and ammonium persulfate with all N-methylol acrylamide monomers uniformly, and then put them into another dropping funnel;

[0041] ③Start stirring and increase the temperature. When the temperature rises to 80°C, add the materials in the 2 dropping funnels dropwise at the same time. After the dropwise addition is completed within 1.5h, contin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com